Cellulose-based nano friction generator with high output performance and preparation method thereof

A triboelectric generator and nano-friction technology, which is applied in the field of materials, can solve problems such as loss of electricity and electrons, and achieve the effects of improving output performance, simple preparation method, and environmental protection and pollution-free preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

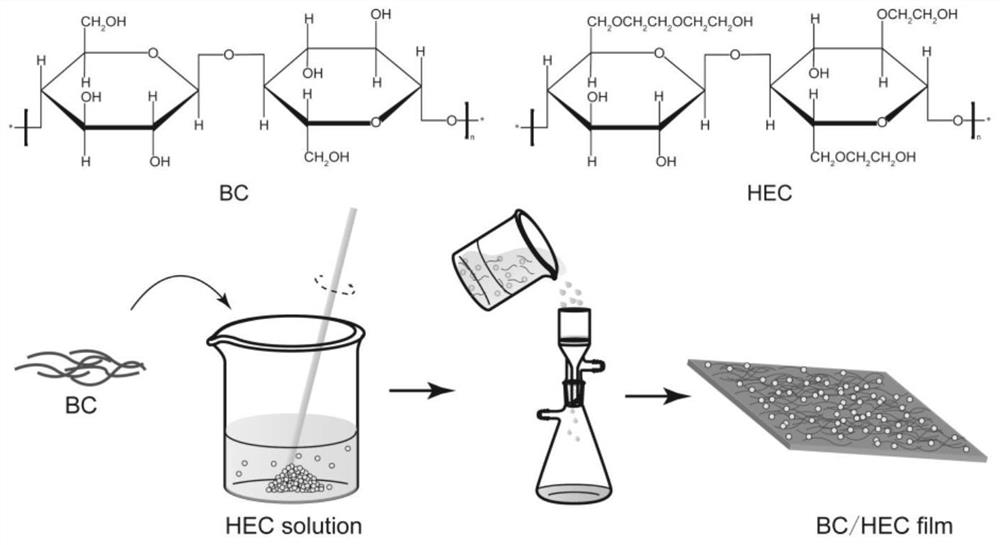

[0033] 1) Weigh 16.36 g of the bacterial cellulose dispersion in a beaker (the bacterial cellulose dispersion is purchased from Chihong Technology, the actual bacterial cellulose content is 0.55%, and the dispersant is water) (implementation Example 1), 14.55g (Example 2), 10.91g (Example 3), and 7.27g (Example 4) were added with 70ml deionized water respectively;

[0034] 2) After weighing 10mg (Example 1), 20mg (Example 2), 40mg (Example 3), and 60mg (Example 4) of hydroxyethyl cellulose powder into a beaker, add 20ml of deionized water to carry out Dissolving, the dissolving process is carried out in a 50°C water bath;

[0035] 3) Add the hydroxyethyl cellulose aqueous solution obtained in step 2) to the bacterial cellulose aqueous solution obtained in step 1) according to the mass ratio, and then use a magnetic stirrer on the stirring table to stir for 10 minutes and then ultrasonically disperse in an ultrasonic cleaner 20min; the mass ratio of the mass of actual bacteria...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com