Quality trimming method for hemispherical harmonic oscillator

A hemispherical resonator and resonator technology, which is applied to surface-polished machine tools, parts of grinding machine tools, metal processing equipment, etc., can solve the problems affecting the quality factor of resonators, high operating requirements, and unfriendly environment, and achieve both The effect of trimming accuracy, simple and flexible operation, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

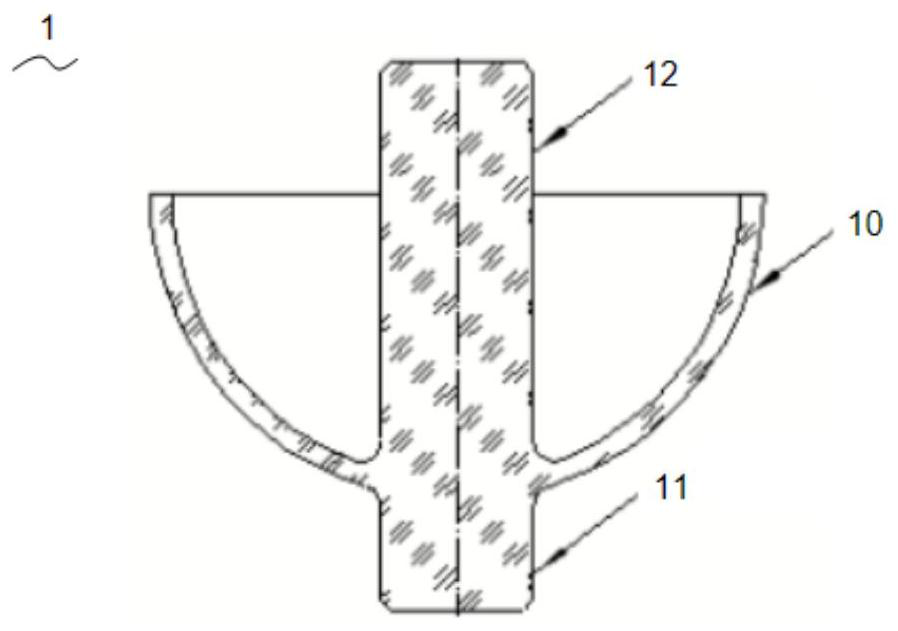

[0029] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

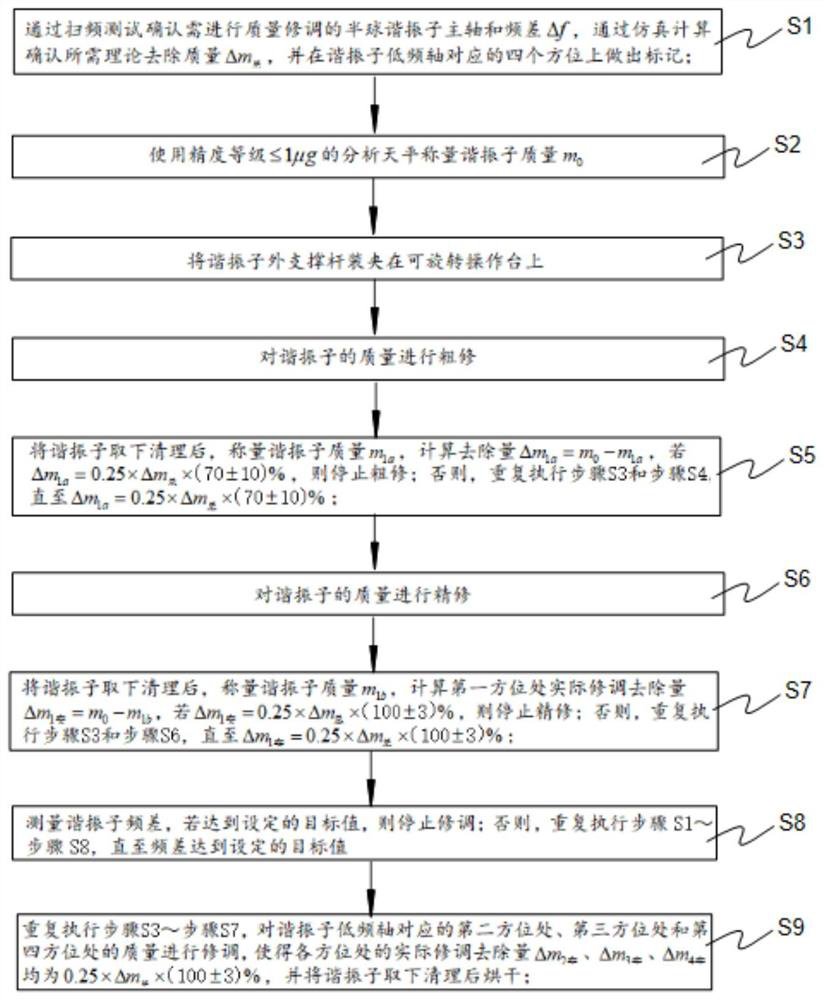

[0030] see figure 1 , figure 1 Shown is the flow chart of the quality adjustment method of the hemispherical harmonic oscillator of the present invention. The quality trimming method of the hemispherical harmonic oscillator includes:

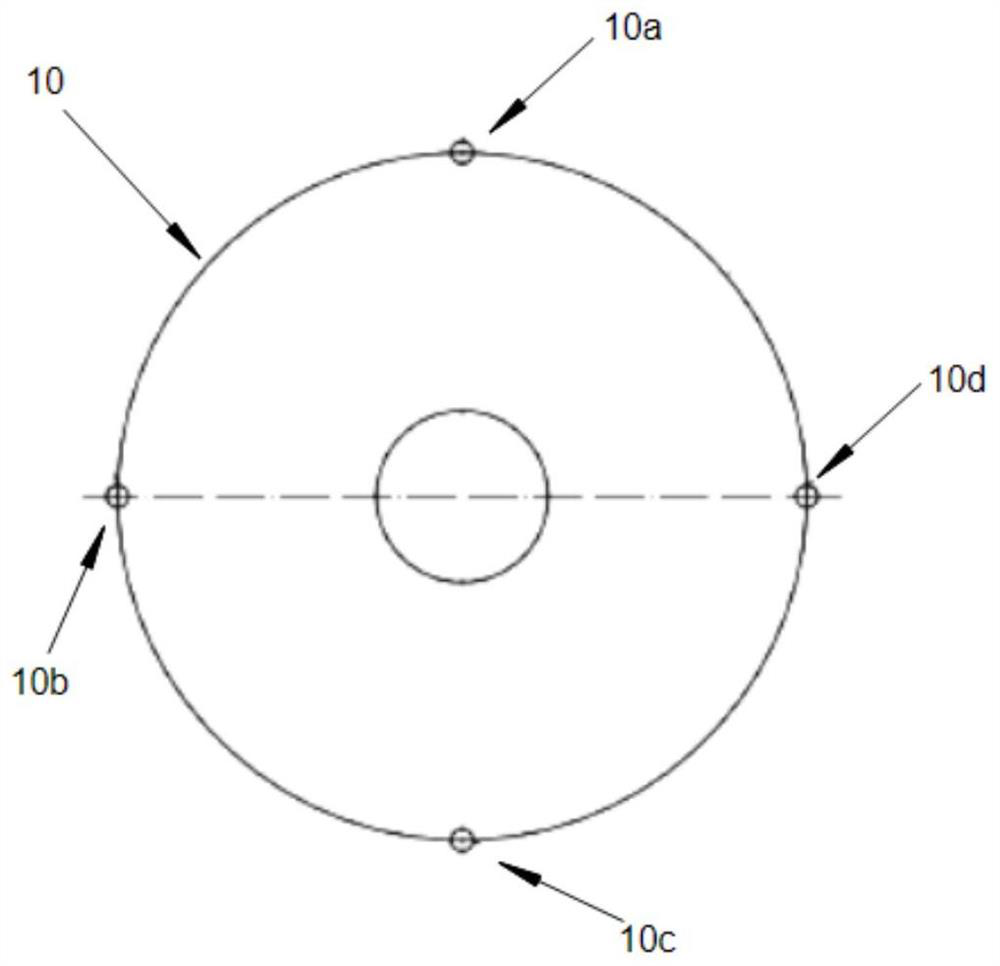

[0031] Execute step S1: Confirm the hemispherical resonator main axis and frequency difference Δf that need to be adjusted by the frequency sweep test, and confirm the required theoretical removal mass Δm by simulation calculation 总 , and make marks on the four directions corresponding to the low frequency axis of the harmonic oscillator;

[0032] Execute step S2: use an analytical balance with an accuracy class ≤ 1 μg to weigh the mass m of the harmonic oscillator 0 ;

[0033] Execute step S3: clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com