Preparation method and application of alpha-(o-chloroaniline) methylene-beta-formylaminopropionitrile

A technology of -formamidopropionitrile and o-chloroaniline, which is applied in the field of preparation of α-methine-β-formamidopropionitrile, can solve the pollution of the operating environment by turnover throwing, complicated operation requirements, and high labor intensity and other issues to achieve the effect of avoiding throwing waste, avoiding pollution of the operating environment, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

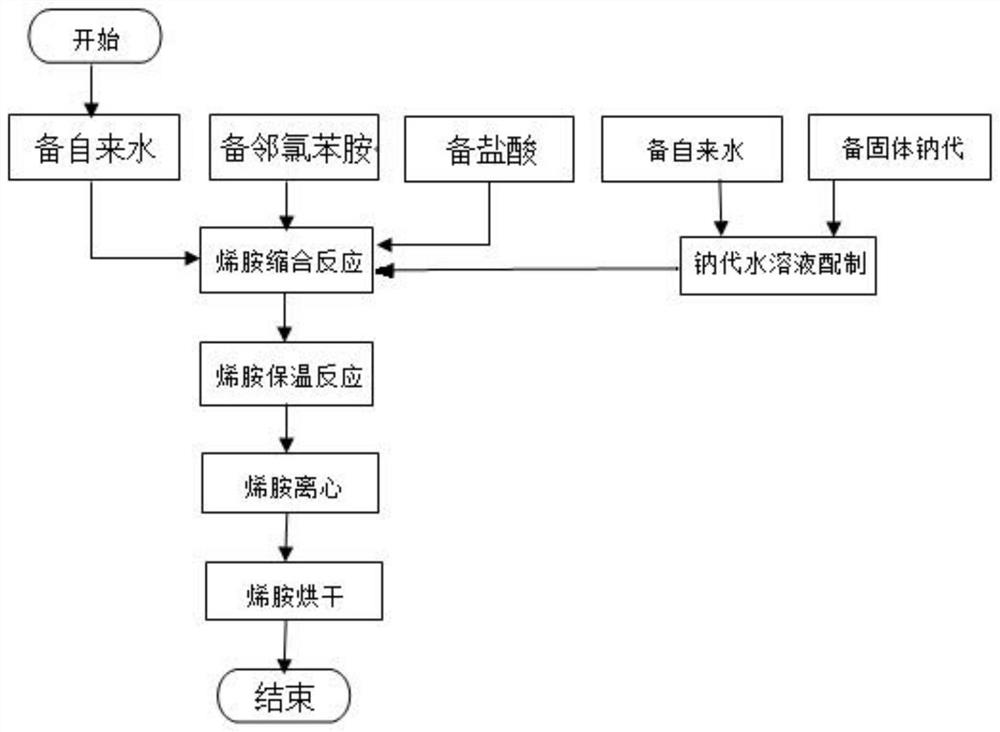

[0033] According to a first aspect of the present invention, a kind of preparation method of α-(o-chloroanilino) methine-β-formamidopropionitrile is provided, comprising the following steps:

[0034] The aqueous solution of α-sodioformyl-β-formamidopropionitrile reacts with the acid solution of o-chloroaniline to obtain α-(o-chloroaniline)methine-β-formamidopropionitrile.

[0035] In the present invention, the aqueous solution of α-sodium formyl-β-formamidopropionitrile is used to replace its solid as a raw material, which avoids the waste of solid materials in the turnover feeding process and the problem of polluting the operating environment, and also reduces The labor intensity of on-site operators is reduced, and since the aqueous solution of α-sodioformyl-β-formylaminopropionitrile is used, there is no need to control the solid α-sodioformyl-β-formyl simultaneously during the reaction process. The addition speed of aminopropionitrile and acid and the control of pH value g...

Embodiment 1

[0061] (a) adding 80g tap water, 76g o-chloroaniline and 105g of hydrochloric acid with a mass fraction of 25% to the reaction flask successively under stirring, and then continuing to stir for 10 minutes to obtain the hydrochloric acid solution of o-chloroaniline;

[0062] (b) 220g tap water is used to dissolve 100g of α-sodioformyl-β-formamidopropionitrile solid (its purity is 80%) to obtain an aqueous solution of α-sodioformyl-β-formamidopropionitrile;

[0063] (c) Add the α-sodioformyl-β-formamidopropionitrile aqueous solution of step (b) to the hydrochloric acid solution of o-chloroaniline in step (a) at a constant speed for about 5 minutes to obtain a reaction system;

[0064] (d) The reaction system of step (c) was incubated at a temperature of 40°C for 8 hours for condensation reaction, and then the product was centrifuged and filtered, and the product was washed with tap water until the pH was 7.0, and then dried to obtain the crude product α-(o-chloroaniline) 126.5 g...

Embodiment 2

[0066] (a) adding 100g tap water, 80g o-chloroaniline and 110g of hydrochloric acid with a mass fraction of 25% to the reaction flask successively under stirring, and then continuing to stir for 15 minutes to obtain the hydrochloric acid solution of o-chloroaniline;

[0067] (b) 250g tap water is used to dissolve 100g of α-sodioformyl-β-formamidopropionitrile solid (its purity is 80%) to obtain an aqueous solution of α-sodioformyl-β-formamidopropionitrile;

[0068] (c) Add the α-sodioformyl-β-formamidopropionitrile aqueous solution of step (b) to the o-chloroaniline hydrochloric acid solution of step (a) at a constant speed for about 10 minutes to obtain a reaction system;

[0069] (d) The reaction system of step (c) is kept at a temperature of 50° C. for 10 hours for condensation reaction, and then the product is centrifuged and filtered, and the product is washed with tap water until the pH is 7.0, and then dried to obtain the crude product α-(o-chloroaniline) 127 g of methi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com