Preparation method of chlorotoxin

A technology for chlorotoxin and peptide segment, which is applied in the field of preparation of chlorotoxin, can solve problems such as low-cost and large-scale industrial production of chlorotoxin, and achieve the effects of shortening synthesis cycle, reducing side reactions and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

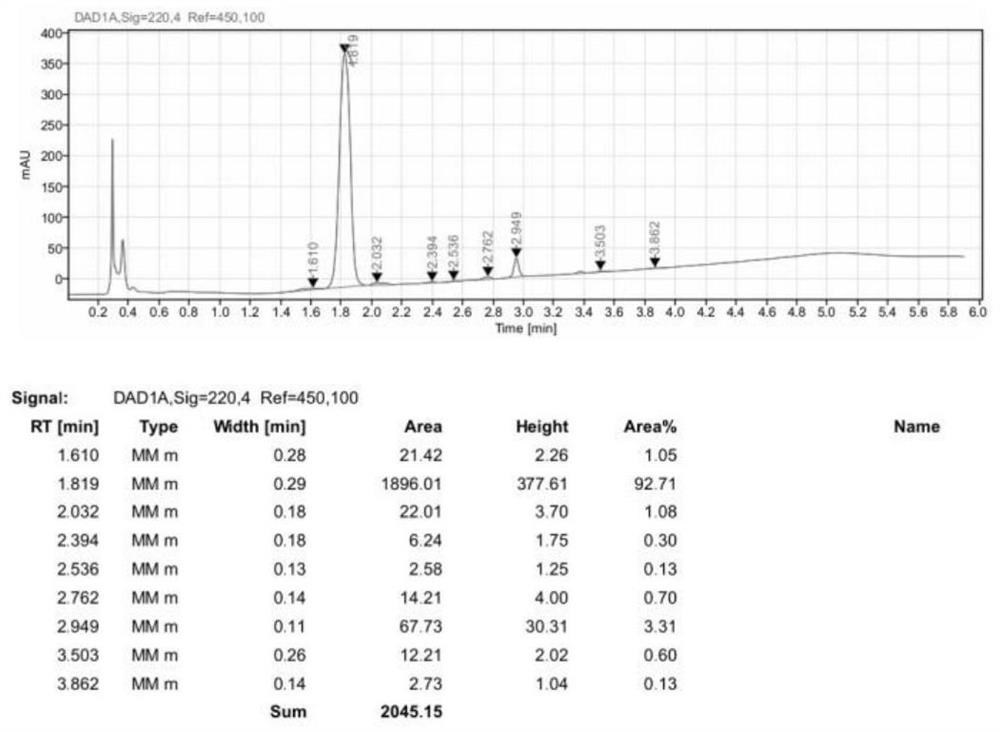

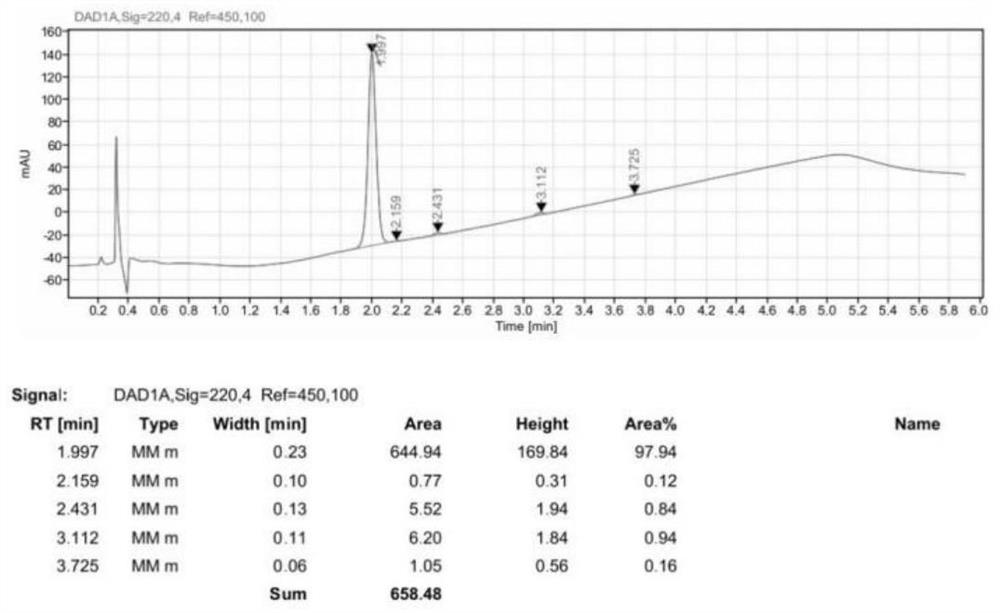

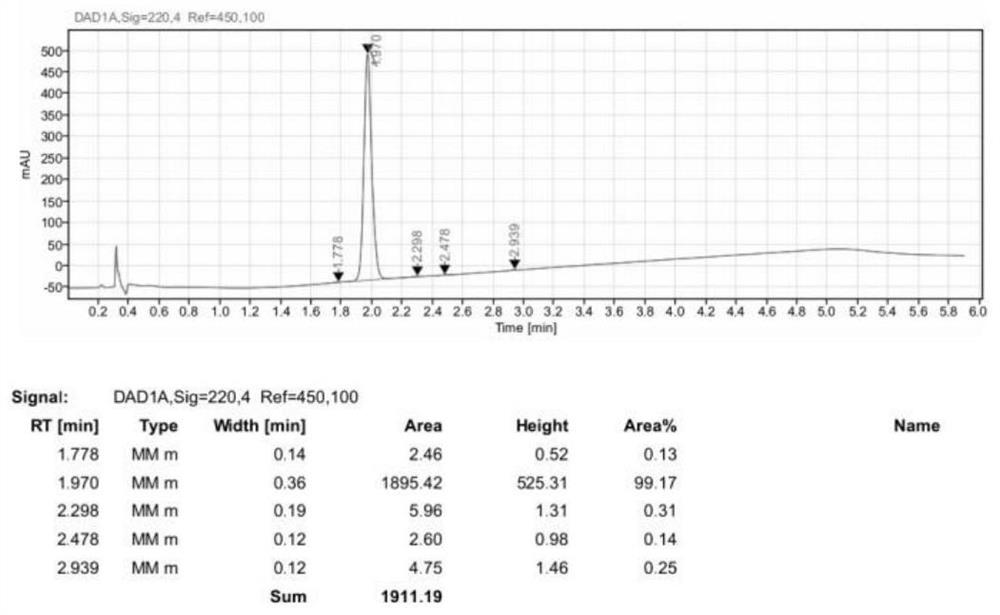

Image

Examples

preparation example Construction

[0049] The present invention provides a preparation method of chlorotoxin, which can be achieved by those skilled in the art by referring to the content of this article and appropriately improving the process parameters. In particular, it should be pointed out that all similar replacements and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention. The method and application of the present invention have been described through preferred embodiments, and relevant personnel can obviously make changes or appropriate changes and combinations to the method and application herein without departing from the content, spirit and scope of the present invention to realize and apply the present invention Invent technology.

[0050] The preparation method of chlorotoxin provided by the invention comprises:

[0051] Step 1: Using Fmoc-AA-OH as raw material, solid-phase step-by-step synthesis to obtain the resin peptide Fmo...

Embodiment 1

[0086] Example 1: Fragment Coupling Method

[0087] step 1:

[0088] Fmoc-Arg(Pbf) 14 -Lys(Boc) 15 -Cys(Trt) 16 -Asp(tBu) 17 -Asp(tBu) 18 -Cys(Trt) 19 -Cys(Trt) 20 -Gly 21 -Gly 22 -Lys(Boc) 23 -Gly 24 -Arg(Pbf) 25 -Gly 26 -Lys(Boc) 27 -Cys(Trt) 28 -Tyr(tBu) 29 -Gly 30 -Pro 31 -Gln(Trt) 32 -Cys(Trt) 33 -Leu 34 -Cys(Trt) 35 -Arg(Pbf) 36 - Synthesis of AM Resin:

[0089] Removal of Fmoc protecting group: Weigh AM Resin (31.646g, 10.0mmol) with a substitution degree of 0.316mmol / g, add it to a solid-phase reaction column, swell the resin with DMF (310ml) for 30 minutes, and drain the solvent. Use DBLK (20% piperidine / DMF, 200ml) to remove the Fmoc protection for 10 minutes, remove the protection twice, and then wash 6 times with DMF (300ml) (take a little resin and add 0.3ml of 5% ninhydrin ethanol solution, Heating at 100 degrees Celsius for 5-10 minutes, the resin will not turn blue).

[0090] Fmoc-Arg(Pbf)-OH coupling: Weigh 12.981g of Fmoc-Arg(Pbf)-OH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com