Disperse dye with high washing fastness and preparation process thereof

A technology for disperse dyes and washing fastness, applied in the field of dyes, can solve the problems of easy decolorization of dyes, complicated production and high cost, and achieve the effects of low cost, simple preparation process steps and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

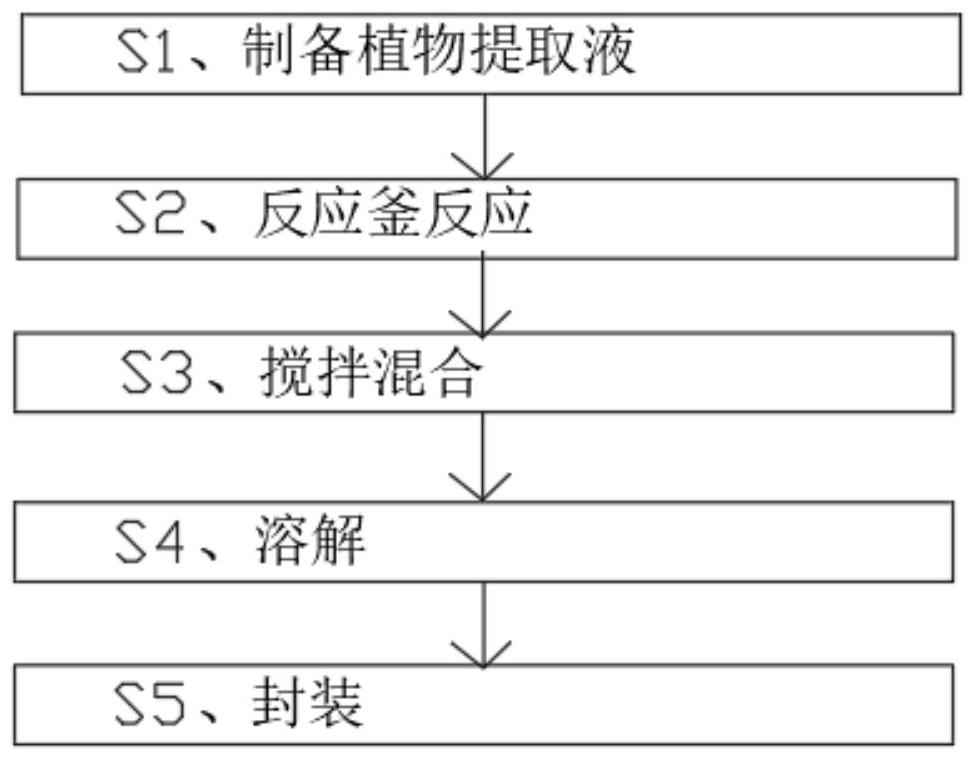

[0025] refer to figure 1 , a disperse dye with high washing fastness, comprising the following components by mass: 60 parts of C.I. Direct Yellow 106 dye, 30 parts of plant extract, 50 parts of o-phenylphenol, 20 parts of methyl salicylate, 40 parts of hematoxylin 4 parts, 4 parts of dibenzodioxazine, 3 parts of cyanuric chloride, 5 parts of anti-sedimentation agent, 4 parts of dispersant, 3 parts of surfactant, 5 parts of stabilizer, 7 parts of antibacterial agent.

[0026] Wherein, the dispersant is a mixture of naphthalenesulfonate formaldehyde condensate NNO and lignosulfonate 85A.

[0027] Wherein, the stabilizer is MF.

[0028] Wherein, the surfactant is fatty amine polyoxyethylene ether two.

[0029] Wherein, the antibacterial agent is anilides.

[0030] Wherein, the anti-deposition agent is sodium citrate.

[0031] This embodiment also discloses a preparation process of disperse dyes with high washing fastness, comprising the following steps:

[0032] S1. Preparat...

Embodiment 2

[0040] refer to figure 1 , a disperse dye with high washing fastness, including the following components by mass: 55 parts of C.I. Direct Yellow 106 dye, 30 parts of plant extract, 54 parts of o-phenylphenol, 24 parts of methyl salicylate, and 32 parts of hematoxylin 5 parts, 5 parts of dibenzodioxazine, 5 parts of cyanuric chloride, 7 parts of anti-sedimentation agent, 5 parts of dispersant, 5 parts of surfactant, 5 parts of stabilizer, 7 parts of antibacterial agent.

[0041] Wherein, the dispersant is a mixture of naphthalenesulfonate formaldehyde condensate NNO and lignosulfonate 85A.

[0042] Wherein, the stabilizer is sodium lignosulfonate.

[0043] Wherein, the surfactant is sulfonated castor oil.

[0044] Wherein, the antibacterial agent is thiazoles.

[0045] Wherein, the anti-deposition agent is ethyl acetate.

[0046] This embodiment also discloses a preparation process of disperse dyes with high washing fastness, comprising the following steps:

[0047] S1. Pr...

Embodiment 3

[0055] refer to figure 1, a disperse dye with high washing fastness, including the following components by mass: 56 parts of C.I. Direct Yellow 106 dye, 34 parts of plant extract, 53 parts of o-phenylphenol, 25 parts of methyl salicylate, and 30 parts of hematoxylin 4 parts, 4 parts of dibenzodioxazine, 3 parts of cyanuric chloride, 5 parts of anti-sedimentation agent, 4 parts of dispersant, 8 parts of surfactant, 5 parts of stabilizer, and 7 parts of antibacterial agent.

[0056] Wherein, the dispersant is a mixture of naphthalenesulfonate formaldehyde condensate NNO and lignosulfonate 85A.

[0057] Wherein, the stabilizer is sodium lignosulfonate.

[0058] Wherein, the surfactant is fatty amine polyoxyethylene ether two.

[0059] Wherein, the antibacterial agent is thiazoles.

[0060] Wherein, the anti-deposition agent is sodium citrate.

[0061] This embodiment also discloses a preparation process of disperse dyes with high washing fastness, comprising the following ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com