Cold spraying copper-containing stainless steel coating with antibacterial and antiviral functions

A copper stainless steel, cold spray technology, applied in metal processing equipment, pressure inorganic powder coating, transportation and packaging, etc., can solve the problem of inability to improve the corrosion resistance of door handles, metal silver luster and aesthetics, and achieve low cost, process High efficiency and the effect of increasing plastic deformation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

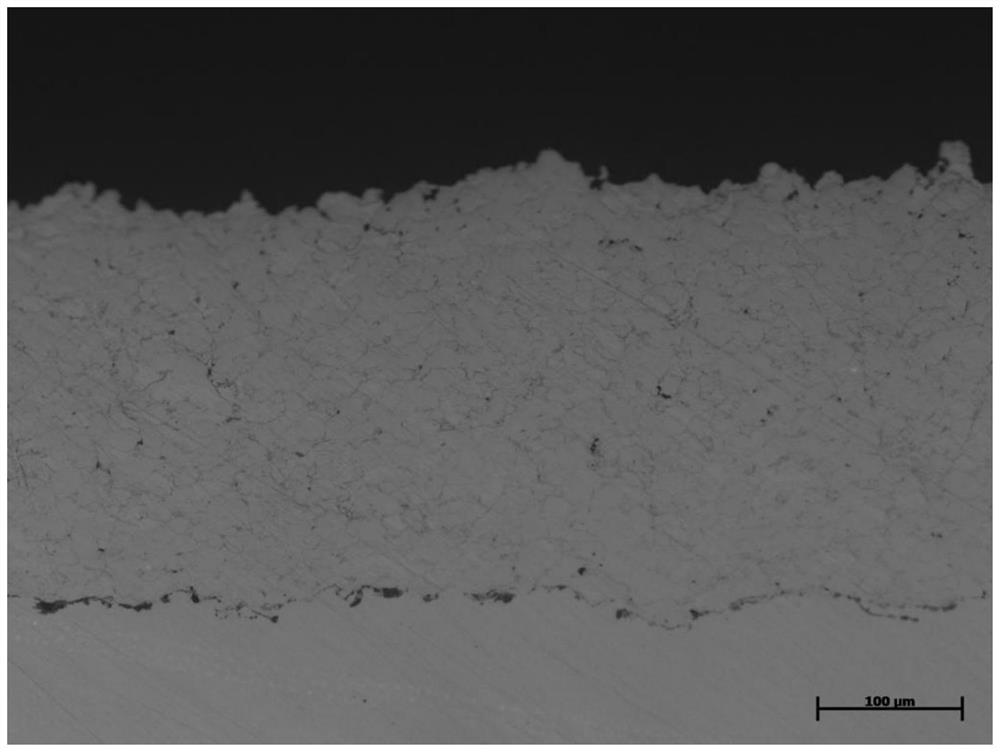

Image

Examples

Embodiment Construction

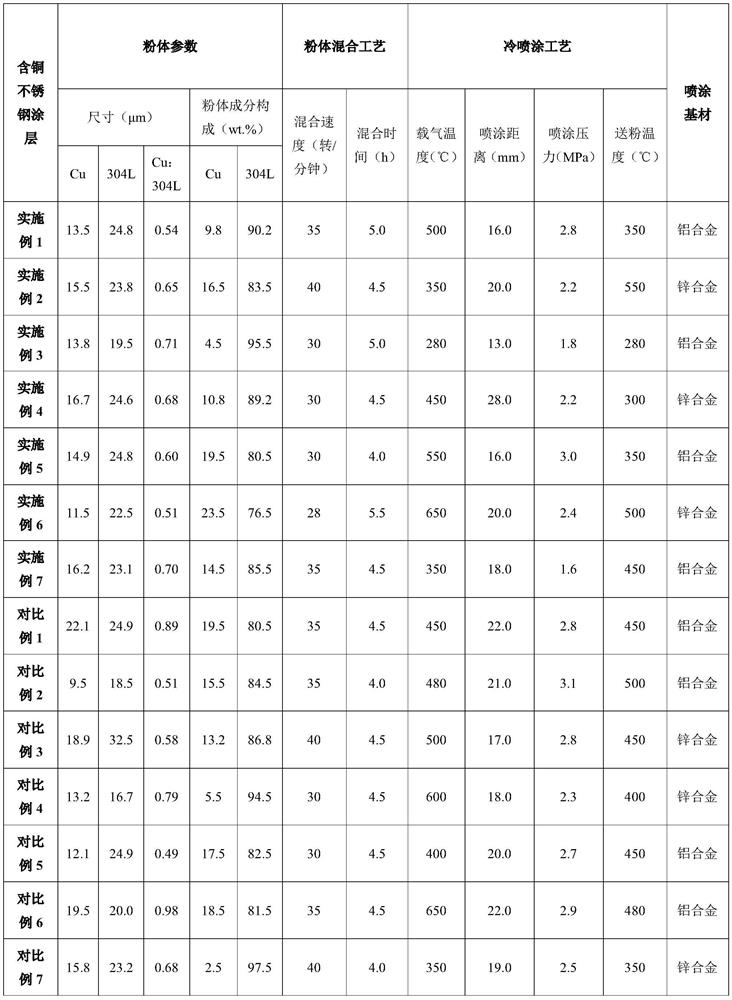

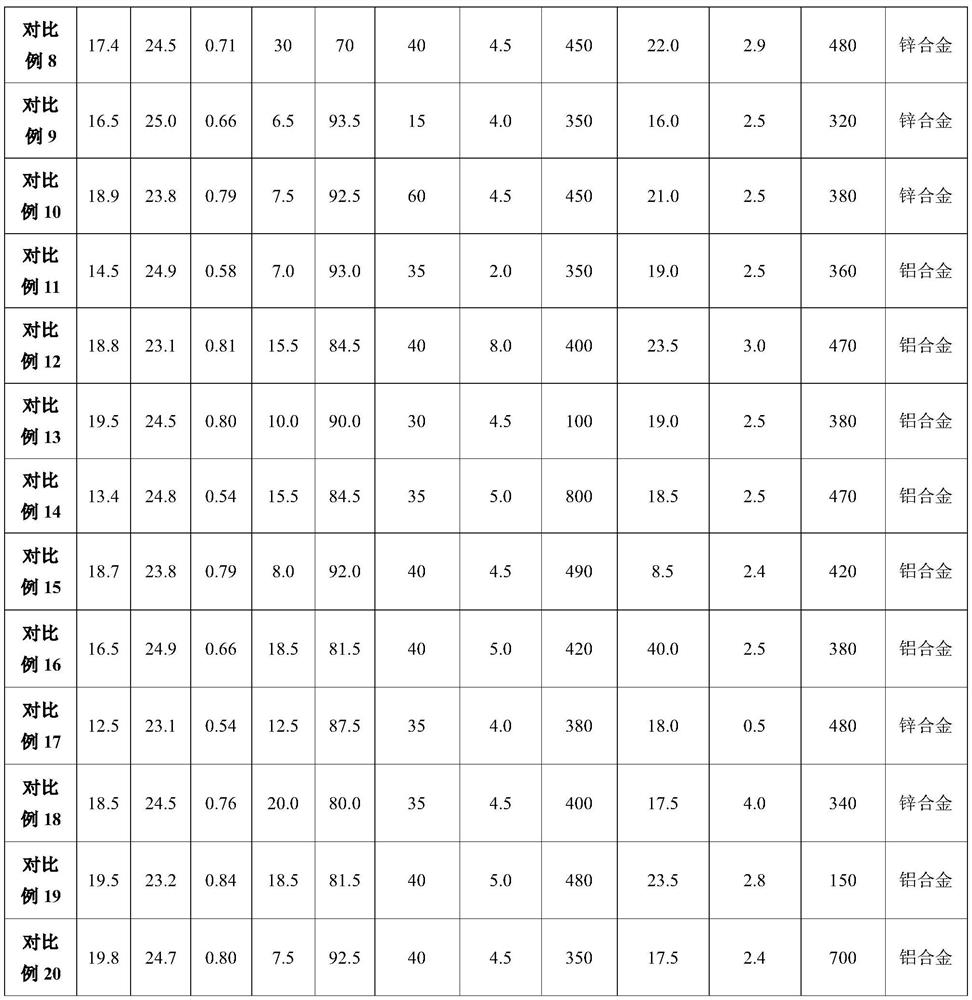

[0023] According to the content of the present invention, the technical solution of the present invention is further described through specific implementation. The examples are only for helping the understanding of the present invention, and are not regarded as specific limitations on the present invention. See Table 1 for the powder composition and cold spraying process parameters used in Examples and Comparative Examples.

[0024] The specific implementation process is as follows:

[0025] (1) Powder mixing: 304L stainless steel powder and pure Cu powder are weighed according to the proportion, and the weighed powder is mixed with a steel ball with a diameter of 5mm, and put into a special mixing tank , to perform uniform mixing under the set speed and time parameters.

[0026](2) Base material preparation: Before cold spraying the base material, use a mixture of ethanol and acetone to degrease the surface of the base material. The mixing ratio of ethanol and acetone is 1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com