A kind of instant antiseptic granule and preparation method thereof

A preservative and instant technology, applied in the fields of botanical equipment and methods, fungicides, biocides, etc., can solve the problems of difficult and rapid release of antibacterial agents, inability to comprehensively and quickly sterilize, and difficult water flow, etc., and achieves good promotion and application prospects. Easy to operate and ensure water-soluble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

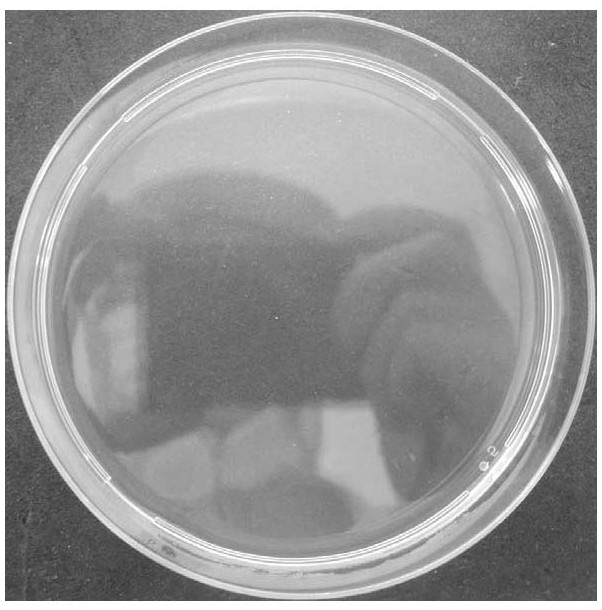

[0033] Preparation of Aqueous Binder Solutions. The binder is mixed with water at a content of 0.5wt% to 15wt% (the content of the binder refers to the mass ratio of the binder to the aqueous solution of the binder), and placed in a heater to heat and stir until the binder dissolve. If the binder content is too low, the bonding effect will be poor; if the binder content is too high, the binder and silver nitrate cannot be mixed uniformly, or the tablet forming and the dissolution rate of the preservative particles will be affected. The temperature of heating and stirring depends on the molecular type of the binder until the binder dissolves. Since each water-soluble polymer has a different thermal upper limit temperature, the heating temperature varies with the type of water-soluble polymer, but it should be lower than its thermal upper limit temperature to prevent property changes. The binder used is a water-soluble polymer, including gum arabic, carboxymethyl cellulose, hy...

Embodiment 1

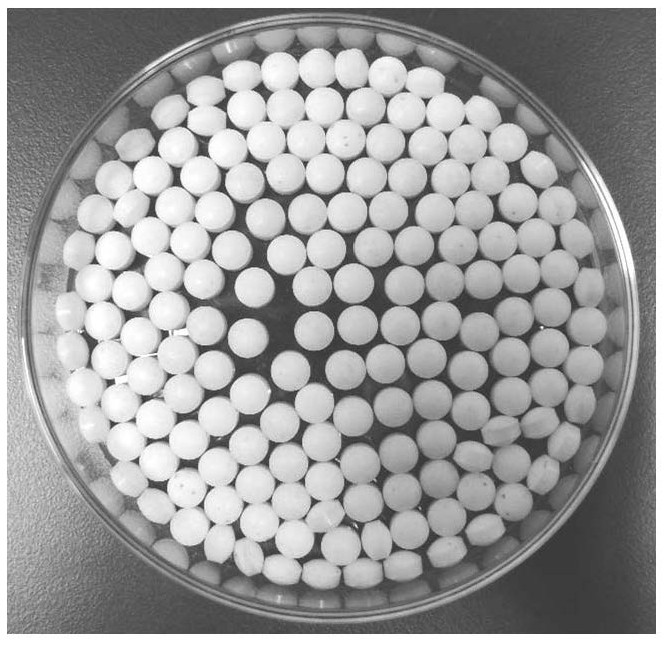

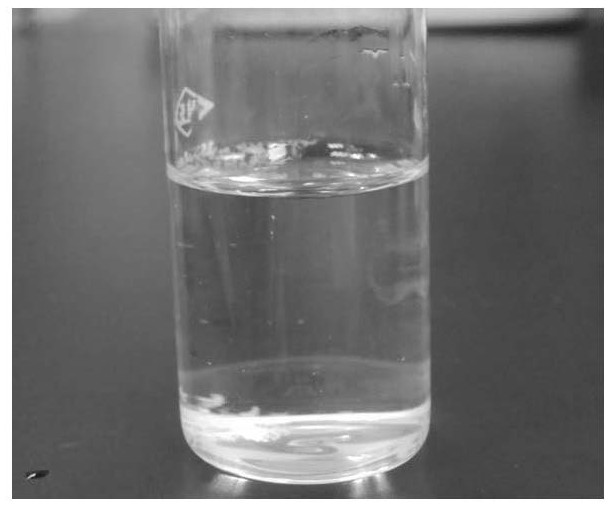

[0039] Preparation of Preservative Granules (Ag-PEG):

[0040] Mix polyethylene glycol (PEG-6000) with water at a content of 0.5 wt %, place in a heater and heat and stir at 60° C. until the polyethylene glycol dissolves. Add 2 mL of 0.5 wt % polyethylene glycol solution to 200 g of silver nitrate, grind and dry at 60° C. for 1 h to obtain a rough mixture. The rough mixture is put into a ball mill tank for ball milling. The ball milling parameters are: the ratio of silver nitrate to balls is 100g:500g, the speed of the ball mill is 20rpm, and the ball milling time is 5min. Transfer the ball mill powder to a mesh sieve for sieving, use a double-layer mesh sieve, the mesh number of the upper mesh is 20 mesh, and the mesh number of the lower mesh is 150 mesh, keep the powder on the 150 mesh mesh, and then 60 °C Dry for 0.5h to obtain granulated powder. The granulated powder was compressed into tablets using a multi-punch tablet machine (pressure 28kN) into granules, and then va...

Embodiment 2

[0046] Preparation of preservative granules (Ag-PVA):

[0047] Mix polyvinyl alcohol (PVA, type 1788, degree of alcoholysis 87% to 89%) with water at a content of 5 wt %, place in a heater and heat and stir at 80° C. until the polyvinyl alcohol dissolves. Add 20 mL of 5 wt % polyvinyl alcohol solution to 200 g of silver nitrate, grind and dry at 60° C. for 1 h to obtain a rough mixture. The rough mixture is put into a ball mill tank for ball milling. The ball milling parameters are: the ratio of silver nitrate to balls: 100g:750g, the speed of the ball mill is 30rpm, and the milling time is 5min. Transfer the ball mill powder to a mesh sieve for sieving, use a double-layer mesh sieve, the mesh number of the upper mesh is 40 mesh, and the mesh number of the lower mesh is 100 mesh, keep the powder on the 100 mesh mesh, and then 60 °C Dry for 0.5h to obtain granulated powder. The granulated powder was compressed into pellets using a multi-punch tablet machine (with a pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com