Preparation method of bismuth alloy sample for EBSD test

A technology of bismuth alloy and EDO86, which is applied in the field of preparation of bismuth alloy samples, can solve the problems of high cost, long cycle, and many sample preparation processes, and achieve the effect of improving imaging quality and high calibration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

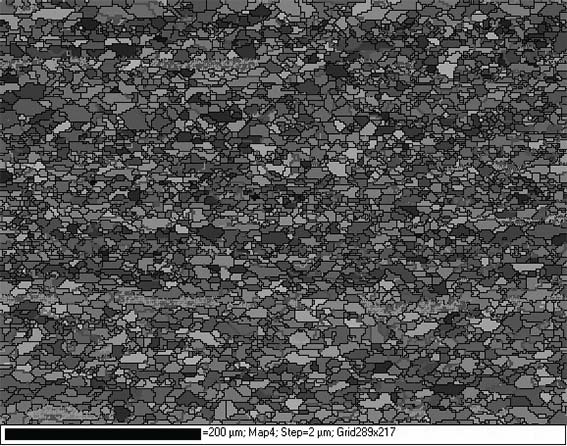

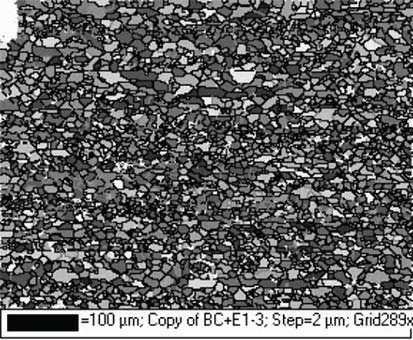

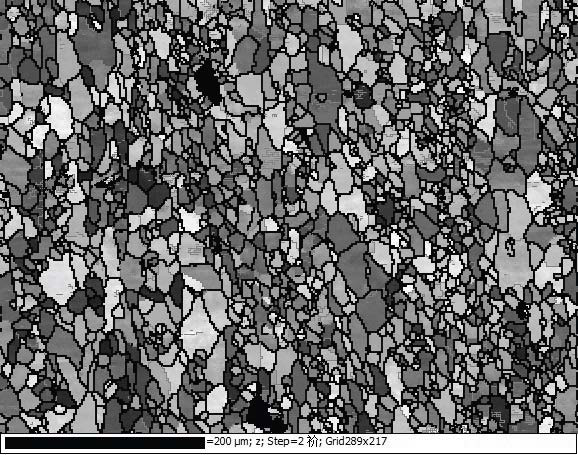

Image

Examples

Embodiment 1

[0025] The preparation method of the bismuth alloy sample used in the EBSD test in this embodiment includes the bismuth alloy sample cutting, grinding, mechanical polishing, electrolytic polishing, cleaning, and drying processes. The specific process steps are as follows:

[0026] (1) The sample is made into a size of 7mm*7mm*3mm in length, width and thickness by wire cutting;

[0027] (2) Use 1500-mesh, 2000-mesh, and 3000-mesh silicon carbide water-grinding paper in turn to rough-grind, fine-grind, and fine-grind the sample;

[0028] (3) Use diamond polishing paste with a particle size of 1.5 μm and 0.5 μm to perform two polishings on the sample in sequence. The speed of the metallographic grinding and polishing machine is 500r / min and 200r / min respectively, and the polishing time is 5min and 3min respectively;

[0029] (4) Put the mechanically polished sample into the electrolytic cell for electrolytic polishing. The electrolytic conditions are: volume ratio of perchloric a...

Embodiment 2

[0034] The preparation method of the bismuth alloy sample used in the EBSD test in this embodiment includes the bismuth alloy sample cutting, grinding, mechanical polishing, electrolytic polishing, cleaning, and drying processes. The specific process steps are as follows:

[0035] (1) The sample is made into a size of 10mm*10mm*2mm in length, width and thickness by wire cutting;

[0036] (2) Use 1500-mesh, 2000-mesh, and 3000-mesh silicon carbide water-grinding paper in turn to rough-grind, fine-grind, and fine-grind the sample;

[0037] (3) Use diamond polishing paste with a particle size of 1.5 μm and 0.5 μm to perform two polishings on the sample in sequence. The speed of the metallographic grinding and polishing machine is 500r / min and 200r / min respectively, and the polishing time is 5min and 3min respectively;

[0038] (4) Put the mechanically polished sample into the electrolytic cell for electrolytic polishing. The electrolytic conditions are: volume ratio of perchloric...

Embodiment 3

[0043] The preparation method of the bismuth alloy sample used in the EBSD test in this embodiment includes the bismuth alloy sample cutting, grinding, mechanical polishing, electrolytic polishing, cleaning, and drying processes. The specific process steps are as follows:

[0044] (1) The sample is made into a size of 10mm*7mm*2mm in length, width and thickness by wire cutting;

[0045] (2) Use 1500-mesh, 2000-mesh, and 3000-mesh silicon carbide water-grinding paper in turn to rough-grind, fine-grind, and fine-grind the sample;

[0046] (3) Use diamond polishing paste with a particle size of 1.5 μm and 0.5 μm to perform two polishings on the sample in sequence. The speed of the metallographic grinding and polishing machine is 500r / min and 200r / min respectively, and the polishing time is 5min and 3min respectively;

[0047] (4) Put the mechanically polished sample into the electrolytic cell for electrolytic polishing. The electrolytic conditions are: volume ratio of perchloric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com