TiO2-SnO2 composite material as well as preparation method and application thereof

A composite material and material layer technology, applied in the field of TiO2-SnO2 composite material and its preparation, can solve the problems of materials not tightly anchored, short cycle life, and unsatisfactory effect, so as to avoid lithium dendrites and improve Safety, the effect of slowing down the decline in capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

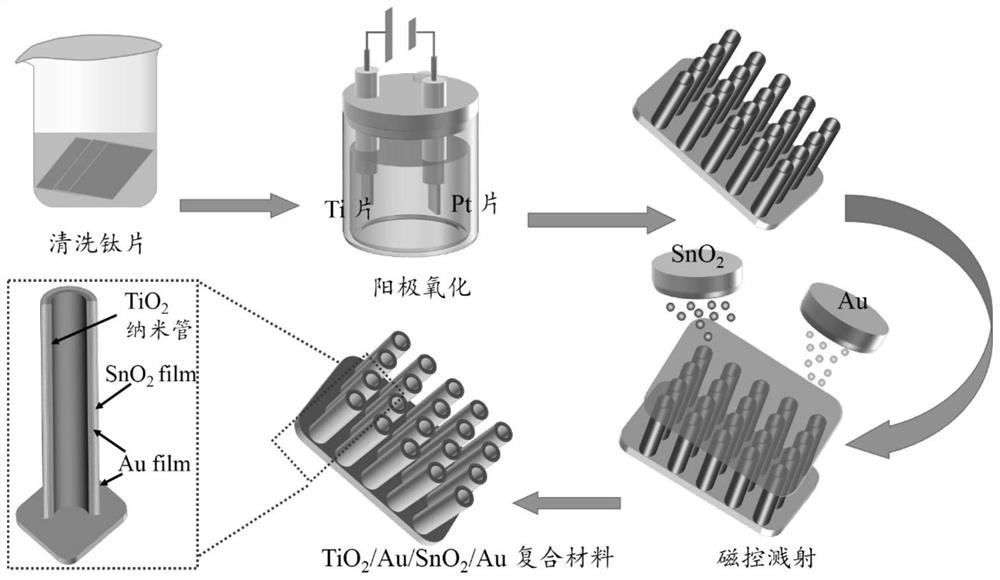

[0045] A kind of TiO 2 / Au / SnO 2 The preparation method of / Au composite material, comprises the following steps:

[0046] (1) Cleaning the titanium sheet: Cut the titanium sheet (99.99% pure) into 40*40*0.1mm, ultrasonically clean it with acetone, alcohol, and deionized water for a certain period of time, and dry it for later use.

[0047] (2) Preparation of electrolyte: take an aqueous solution of 2wt% HF, 2wt% H 2 O is obtained by mixing 96 wt% diethylene glycol.

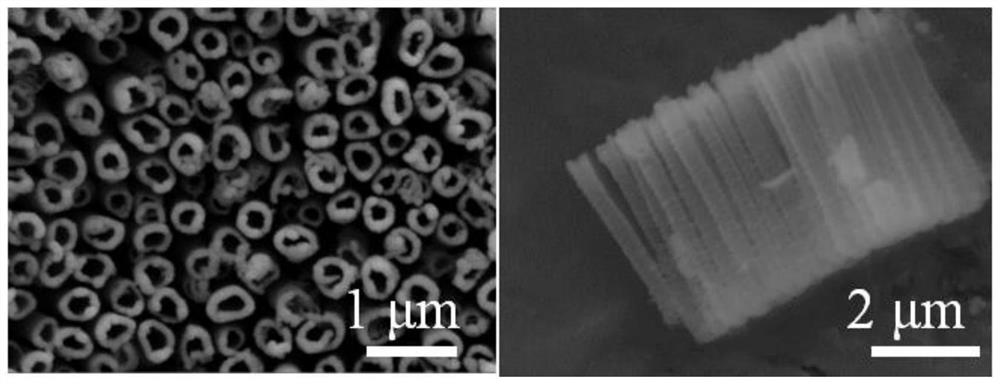

[0048] (3) Anodic oxidation: use the titanium sheet cleaned above as the anode, the platinum sheet as the cathode, use the mixed solution in step (2) as the electrolyte, apply a DC voltage of 60V, and oxidize for 16 hours in the configured electrolyte, and then Continue to oxidize and oxidize for 16 hours in the electrolyte after primary oxidation to obtain TiO 2 Nanotube array, take the second oxidized TiO 2 Nanotube arrays are available.

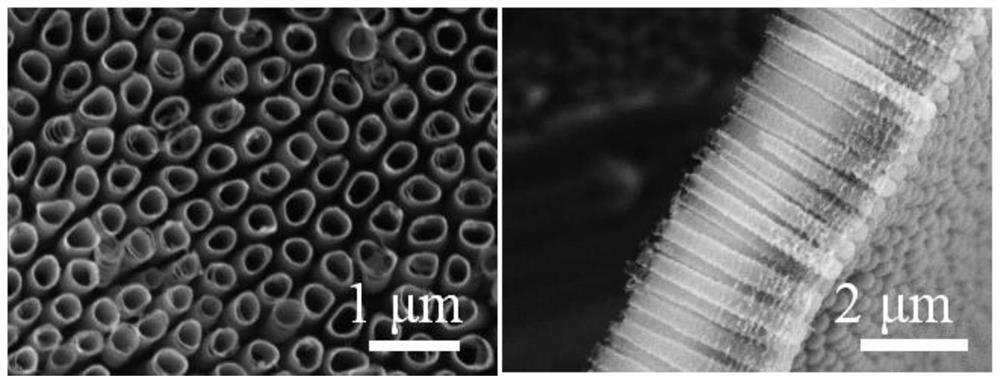

[0049] (4) Magnetron sputtering: the pure TiO prepared in step (3) ...

Embodiment 2

[0053] A kind of TiO 2 / Ag / SnO 2 The preparation method of / Ag composite material, comprises the following steps:

[0054] (1) Cleaning the titanium sheet: Cut the titanium sheet (99.99% pure) into a certain specification, use acetone, alcohol, and deionized water to ultrasonically clean it for a certain period of time, and dry it for later use.

[0055] (2) Preparation of electrolyte: take an aqueous solution of 2wt% HF, 2wt% H 2 O is obtained by mixing 96 wt% diethylene glycol.

[0056] (3) Anodic oxidation: use the titanium sheet cleaned above as the anode, the platinum sheet as the cathode, use the mixed solution in step (2) as the electrolyte, apply a DC voltage of 60V, and oxidize for 16 hours in the configured electrolyte, and then Continue to oxidize and oxidize for 16 hours in the electrolyte after primary oxidation to obtain TiO 2 Nanotube array, take the second oxidized TiO 2 Nanotube arrays are available.

[0057] (4) Magnetron sputtering: the pure TiO prepare...

Embodiment 3

[0061] A kind of TiO 2 / Cu / SnO 2 The preparation method of / Cu composite material, comprises the following steps:

[0062] (1) Cleaning the titanium sheet: Cut the titanium sheet (99.99% pure) into a certain specification, use acetone, alcohol, and deionized water to ultrasonically clean it for a certain period of time, and dry it for later use.

[0063] (2) Preparation of electrolyte: take an aqueous solution of 2wt% HF, 2wt% H 2 O is obtained by mixing 96 wt% diethylene glycol.

[0064] (3) Anodic oxidation: use the titanium sheet cleaned above as the anode, the platinum sheet as the cathode, use the mixed solution in step (2) as the electrolyte, apply a DC voltage of 60V, and oxidize for 16 hours in the configured electrolyte, and then Continue to oxidize and oxidize for 16 hours in the electrolyte after primary oxidation to obtain TiO 2 Nanotube array, take the second oxidized TiO 2 Nanotube arrays are available.

[0065] (4) Magnetron sputtering: the pure TiO prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com