Preparation method of NiMoCu catalyst with nano-porous surface

A surface porous, nanoporous technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention provides a method for preparing a surface nanoporous NiMoCu catalyst, and the specific implementation method is as follows.

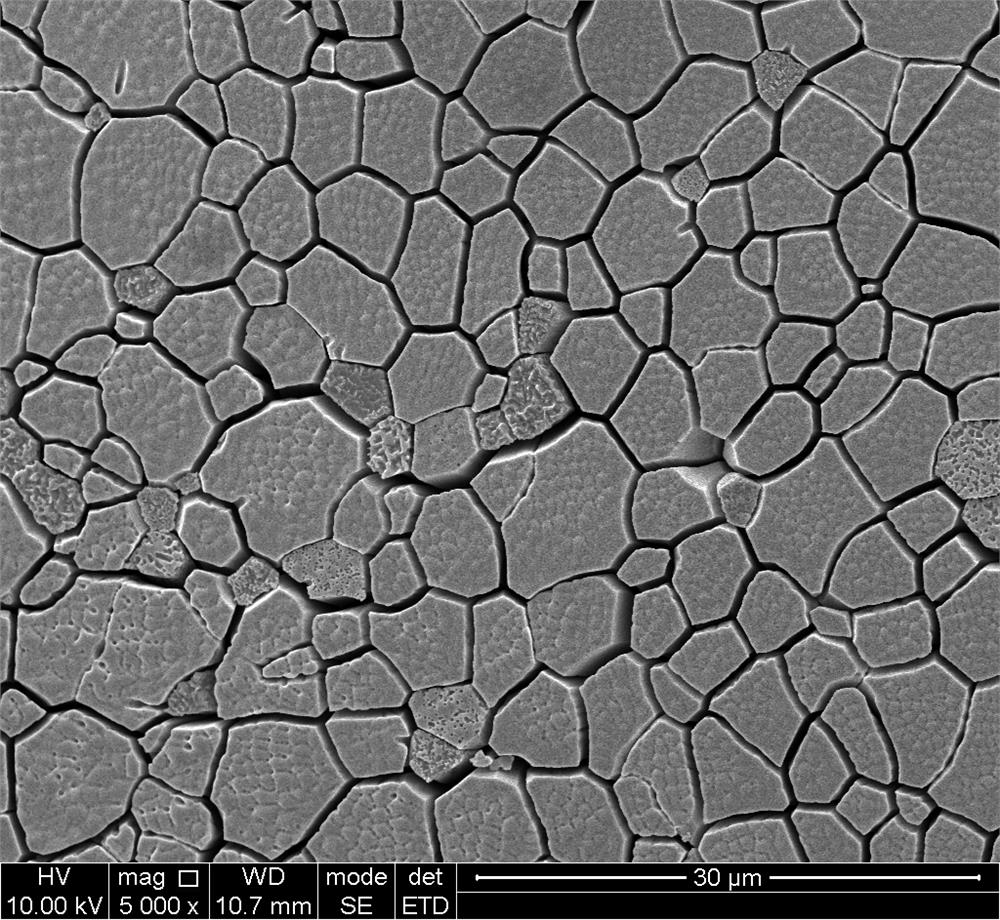

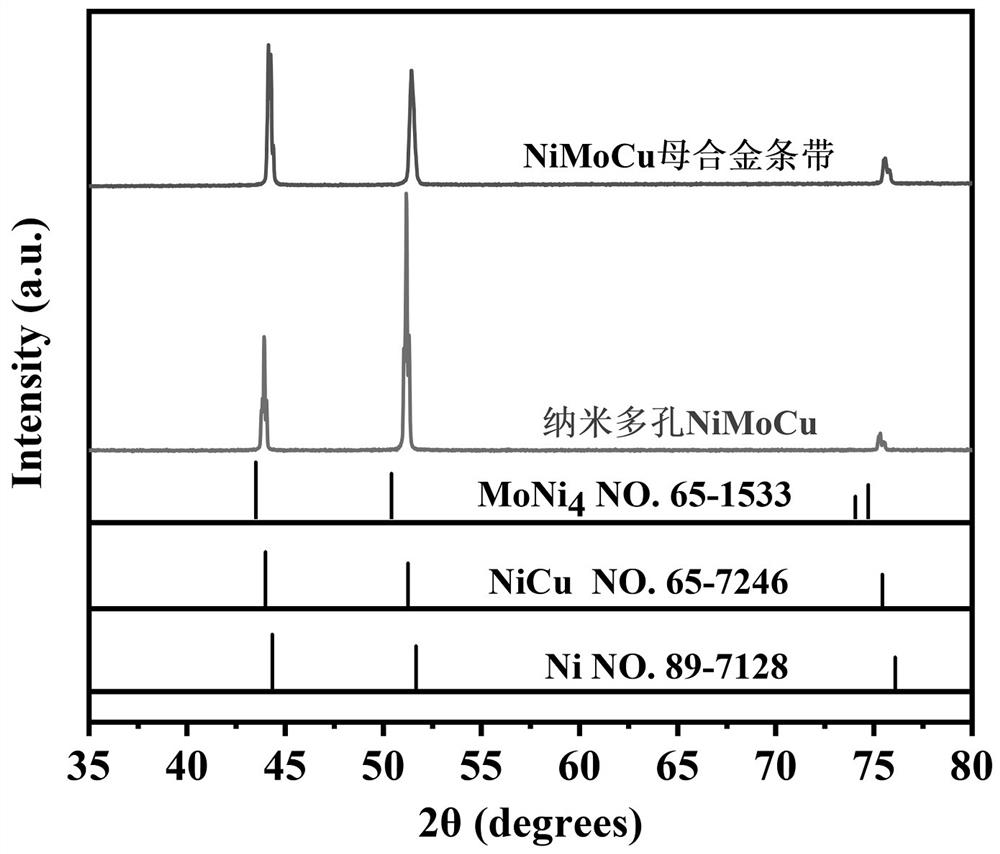

[0019] High-purity Ni, Cu, Mo ingots are made into Ni by arc melting technology according to the atomic ratio of 74:20:6 74 Mo 6 Cu 20 master alloy. Ni 74 Mo 6 Cu 20 Master alloy strips, and cut the obtained master alloy strips into 1×0.2cm 2 spare.

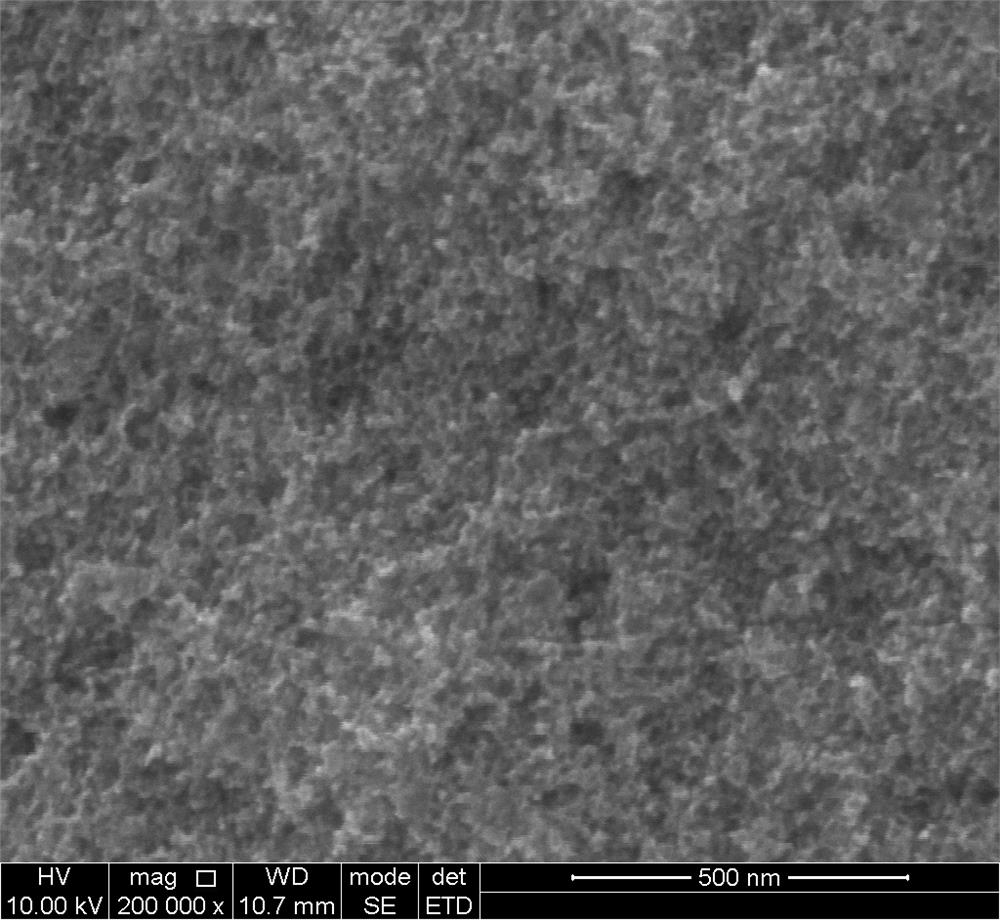

[0020] The Ni obtained by ultrasonic cleaning with acetone and ultrapure water 74 Mo 6 Cu 20 The master alloy strip was dried for 20 minutes and connected to the electrochemical workstation as the working electrode in the three-electrode system. At the same time, the same method was used to treat the gold sheet as an auxiliary electrode; the Ag / AgCl electrode was used as a reference electrode, and it was used as an auxiliary electrode at 0.5M H 2 SO 4 electrochemical etching. The etching voltage is 1.25V (vs.Ag / AgCl), and the etching time is 300s. After the etching is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com