Alloy bone trabecular acetabular cup with gradient porosity and manufacturing method thereof

A technology of gradient pores and manufacturing methods, which is applied in the direction of acetabular sockets, hip joints, joint implants, etc., can solve problems such as unfavorable bone tissue ingrowth, stress shielding, and less load on human bones, so as to reduce weight and Stress shielding, comfort-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

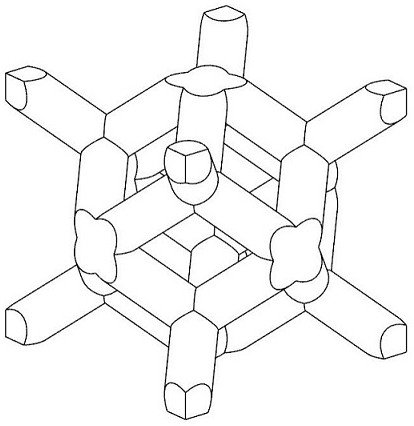

[0025] Such as figure 1 As shown, an alloy trabecular acetabular cup with gradient porosity, including a trabecular structure array filled with trabecular layers on the surface of the acetabular cup; the trabecular structure array consists of more than one trabecular structure Composition; the trabecular bone layer on the surface of the acetabular cup is divided into regions according to its stress range, and each region is filled with the corresponding porosity of the trabecular bone structure according to the requirements of the compressive strength; the porosity of the trabecular bone structure is controlled by the diameter of its struts. The trabecular bone structure on the surface of the acetabular cup is made of Ti6Al4V alloy. The diameter of the struts of the trabecular structure is between 125 and 250 μm, and the porosity can be adjusted within the range of 60% to 90%.

[0026] The porosity of the trabecular structure on the surface of the acetabular cup presents a gra...

Embodiment 2

[0028] A method for manufacturing an alloy trabecular acetabular cup with gradient porosity, comprising the following steps:

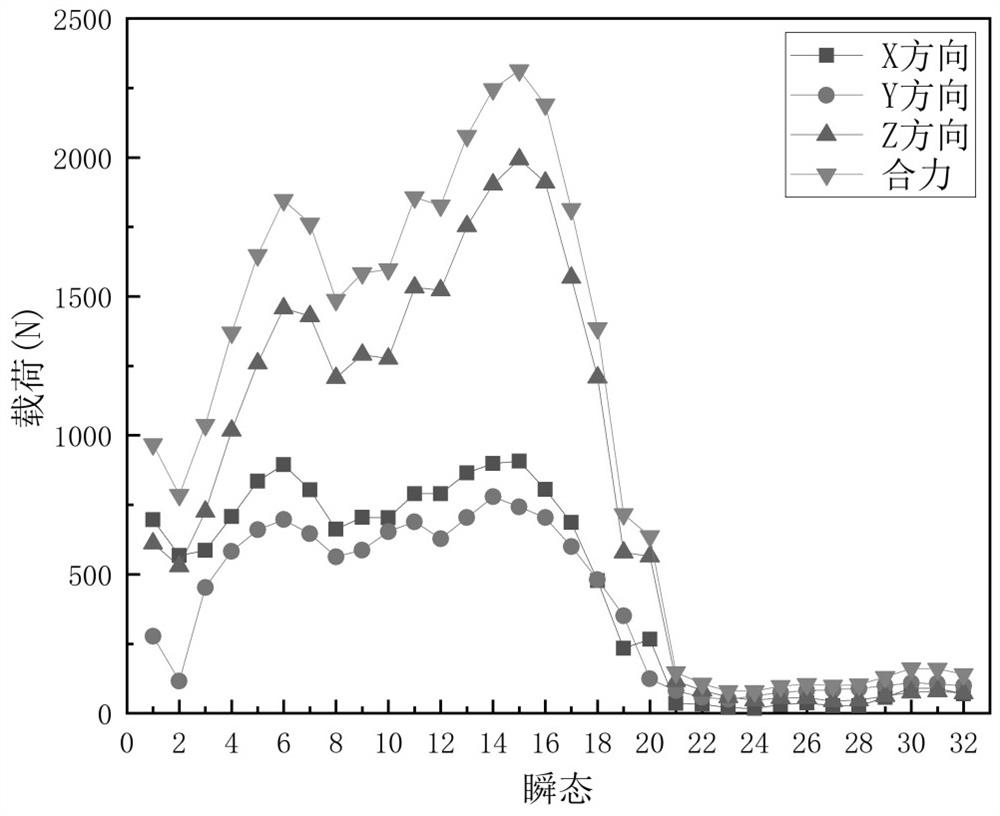

[0029] Step 1: Simulate the stress distribution of the trabecular layer on the surface of the acetabular cup: establish a total hip prosthesis model, and perform finite element simulation on more than one transient load in a complete gait cycle; obtain the stress of each transient Cloud map; superimpose the stress cloud map of each transient state to obtain the stress distribution map of the trabecular bone layer;

[0030] Step 2: Divide the trabecular bone layer area: obtain the stress interval of the trabecular bone layer from the stress distribution diagram of the trabecular bone layer, and divide the trabecular bone layer into areas according to the stress interval;

[0031] Step 3: Determine the safety factor of each region of the trabecular layer: determine the safety factor of each region of the trabecular layer according to the maximum stress o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com