Dental implant and preparation method thereof

A technology for dental implants and a processing method, applied in the field of dental implants, dental implants and their preparation, can solve the problems of unstable long-term fixation effect, poor bone ingrowth effect, and recovery after surgery failure, and achieve effective mechanical maintenance. Support, high mechanical strength, reducing the effect of stress shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

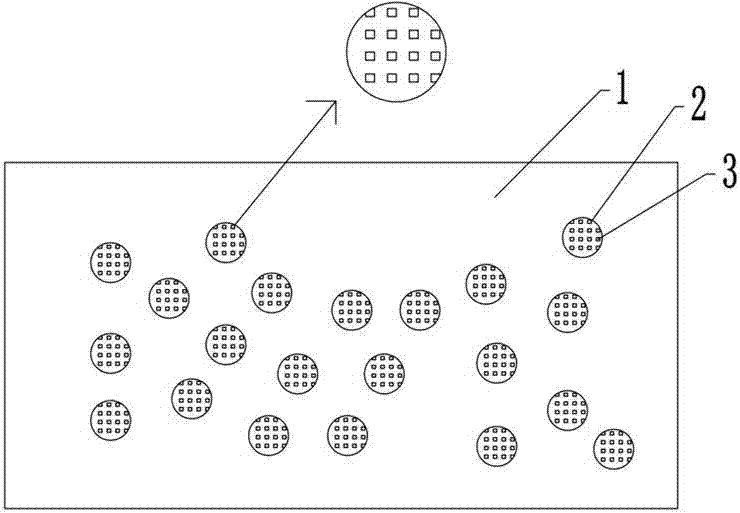

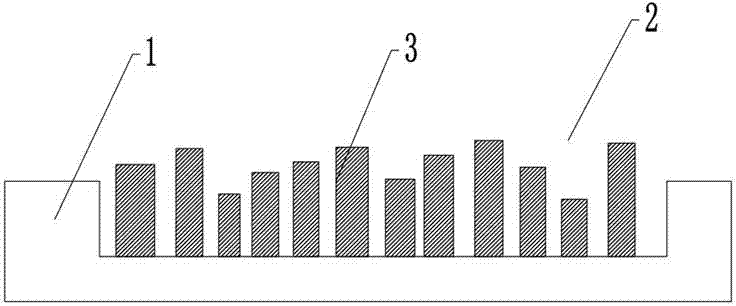

[0019] In the preparation method of the dental implant of the present invention, various processing methods are used to form holes or grooves on the dental implant body, and then the additive manufacturing technology is used to construct columnar protrusions, spherical protrusions or other three-dimensional shapes in the holes or grooves.

[0020] The various processing methods are any processing methods known in the art that can form holes or grooves on the dental implant body, such as casting, forging, laser melting, acid etching and the like.

[0021] The additive manufacturing technology is preferably but not limited to 3D printing.

[0022] The dental implant body is preferably but not limited to be made by forging a biocompatible metal material, wherein the biocompatible metal material is preferably but not limited to pure titanium, titanium alloy, cobalt-chromium alloy, wherein the titanium alloy includes Compared with traditional titanium alloys, Ti-8Fe-8Ta-4Zr and Ti-...

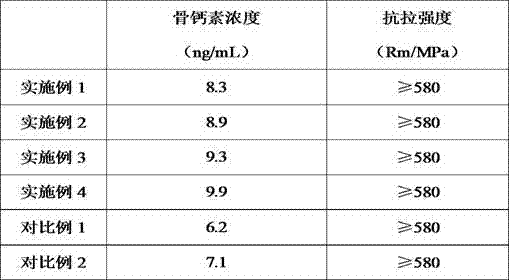

Embodiment 1

[0024] A dental implant, the preparation method of which comprises: manufacturing a dental implant body by forging pure titanium, and then using a laser melting method to form holes or grooves on the surface of the dental implant body and human bone in long-term contact, and then 3D printing is used to construct columnar protrusions, spherical protrusions or other three-dimensional shapes in the holes; the laser melting method adopts the existing technology, so that the diameter of the holes is 5 μm, the depth is 0.5 μm, and the width of the grooves is 5 μm, and the depth is 0.5 μm; The 3D printing technology adopts the existing technology, so that the height of the columnar protrusion, spherical protrusion or other three-dimensional shapes is 0.1 μm.

Embodiment 2

[0026] A dental implant, the preparation method of which comprises: using a forging machine to manufacture a dental implant body through pure titanium, and then using a laser melting method to generate holes or grooves on the surface of the dental implant body and human bone in long-term contact, Then 3D printing is used to construct columnar protrusions, spherical protrusions or other three-dimensional shapes in the holes; the laser melting method adopts the existing technology, so that the hole diameter is 100 μm, the depth is 20 μm, and the groove width is 100 μm, and the depth is 20 μm; The 3D printing technology adopts the existing technology to make the height of the columnar protrusion, spherical protrusion or other three-dimensional shapes be 25 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com