Conveyor with dust falling function for large mine field

A technology for conveyors and mines, applied in conveyors, conveyor objects, electromechanical devices, etc., can solve the problems of reducing environmental protection and conveying effect, diffuse impurities such as dust and debris, endangering the health of workers, etc., to reduce the temperature. , The effect of easy work and smooth conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

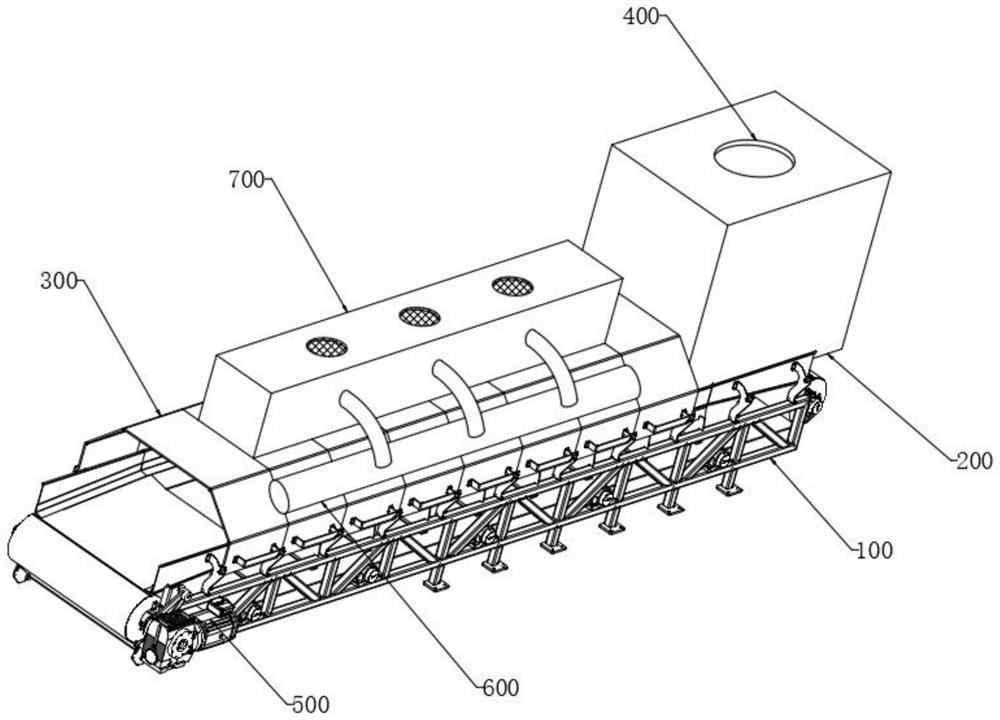

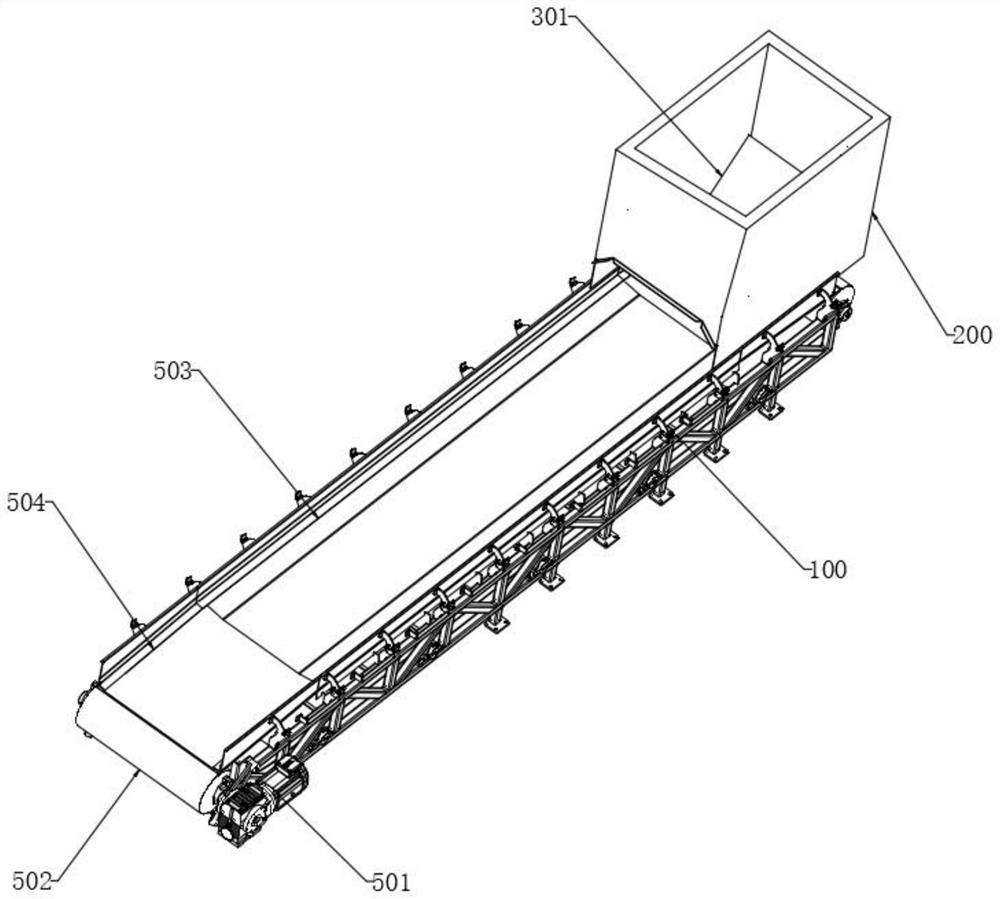

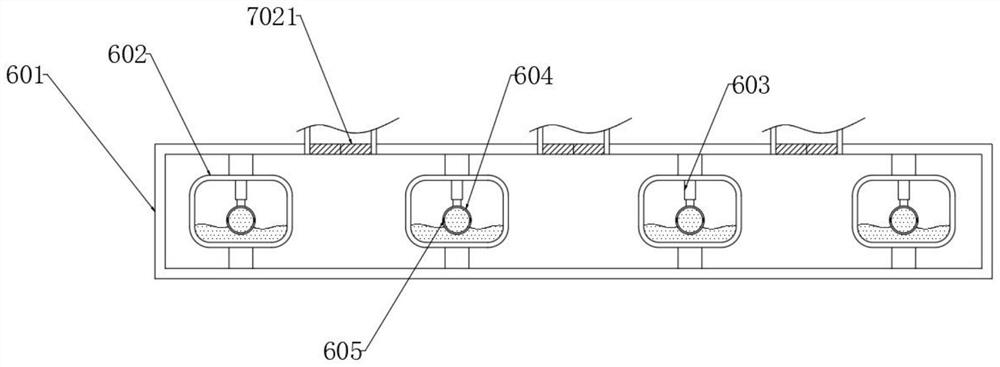

[0041] See Figure 1-7 , A large mine is used as a conveyor having a dust-free function, including the mounting frame 100, and the upper end of the mounting frame 100 is fixedly connected with the conductive frame 200, and the upper end of the conductive frame 200 is blown with the feed port 400, the mounting frame 100 The surface is mounted having a dust collecting shield 300, and the outer end of the conductive frame 200 is opened, and the conductive frame 200 is in communication with the inside of the dust collecting shield 300, and the outer end of the mounting frame 100 is installed with conveying drive. The mechanism 500, the outer end of the dust collecting mechanism 600 is mounted, and the upper end of the dust collecting mechanism 300 is mounted with a pneumatic adsorption mechanism 700, and the present scheme drives the rotating roller 502 and the conveyor belt in the conveying drive mechanism 500. 503 Turn, achieve smooth delivery of ore raw materials, during conveying, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com