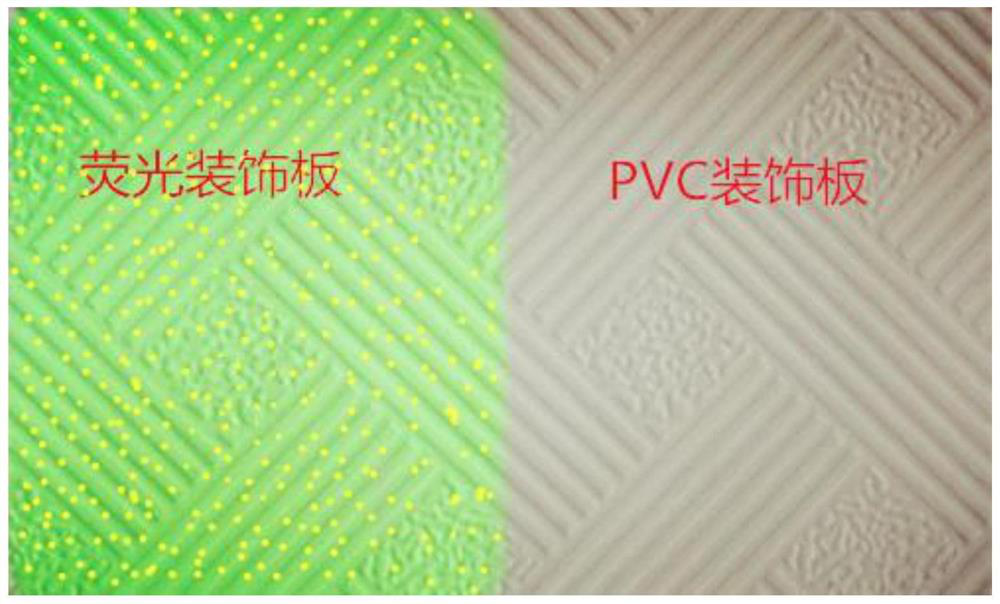

Fluorescent gypsum decorative plate and preparation process thereof

A preparation process and technology for decorative panels, applied in luminous coatings, devices for coating liquid on surfaces, special surfaces, etc., can solve problems such as weak functions and single functions, and achieve the effect of saving costs, costs, and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

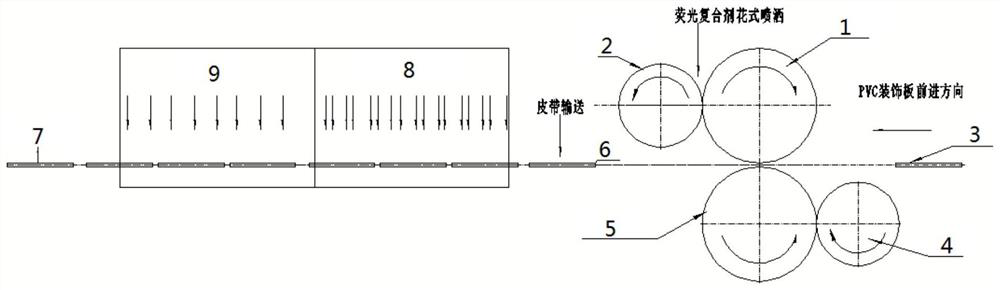

[0048] The present invention also provides a preparation process of fluorescent gypsum board, comprising the following steps:

[0049] A) heating and mixing the mixing aid, stabilizer, coagulation accelerator, adhesion aid, dispersion aid and fluorescent organic colorant, and filtering to obtain a fluorescent composite preparation;

[0050] B) the fluorescent composite preparation is coated on the surface of the spraying roller body by a fancy spraying device, the gypsum decorative board pasted on the film is passed between the spraying roller body and the supporting roller below, and the fluorescent composite preparation is sprayed on the surface of the pasted film;

[0051] C) the gypsum decorative board sprayed with the fluorescent composite preparation obtained in the step B) enters the drying equipment through a conveying device, and is dried to obtain a gypsum decorative board composited with a fluorescent coating;

[0052] D) Compounding a transparent protective layer o...

Embodiment 1

[0066] Raw material formula:

[0067] Composition and proportioning of fluorescent composite preparation: 83.5% mixing aid (80% tung oil or rapeseed oil, 16% xylene and 4% acrylic resin), 3.4% mineral synthetic wax (stabilizer), 2.6 % industrial acidified animal and vegetable protein (coagulation accelerator), 1.5% rosin (adhesive preparation), 6.4% white mineral oil (dispersion aid), 2.6% zinc sulfide (fluorescent organic pigment).

[0068] According to the above-mentioned raw material formula, it is added into non-metallic mixing and compounding equipment, heated to 150°C for mixing, and filtered to obtain a fluorescent compound preparation.

[0069] (1) Through the pump body made of special ceramic material (or the material contact part is made of rubber material), the above-mentioned fluorescent compound preparation is transported to the fancy spraying device above the application roller body according to a certain flow rate and pressure, and the above-mentioned fluorescen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com