Prestressed steel structure tool rod piece system

A tool rod and steel structure technology, applied to structural elements, building components, building reinforcements, etc., to reduce weight, avoid long-term adverse stress, and improve the effect of turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

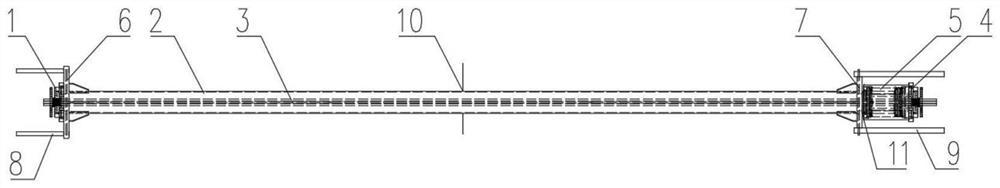

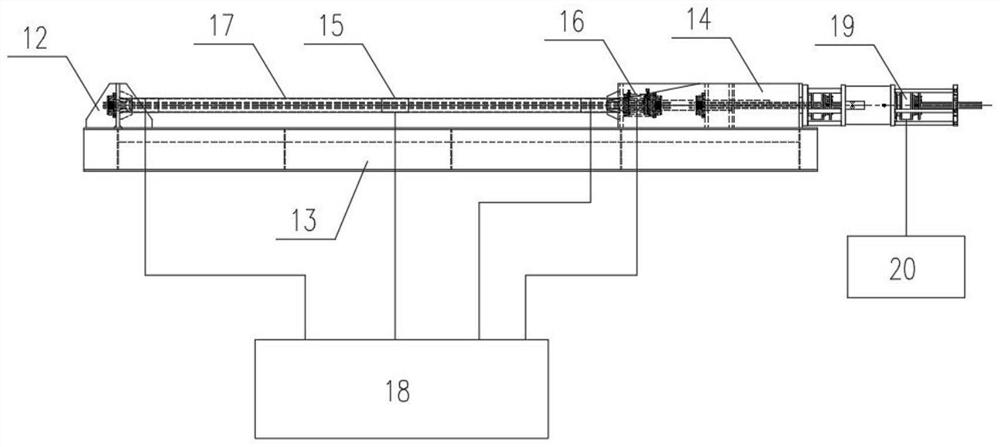

[0038] Below in conjunction with accompanying drawing, the specific embodiment of a kind of prestressed steel structure member system performance test verification of the present invention is described:

[0039] Such as figure 1 As shown, a prestressed steel structure rod system includes a fixed end anchor plate 1, a steel rod 2, a steel strand 3, a tension end anchor plate 4, a tension jack 5, a first end sealing plate 6, The second end sealing plate 7, the first connecting plate 8, the second connecting plate 9, the stress sensor 10, the displacement sensor 11 and so on.

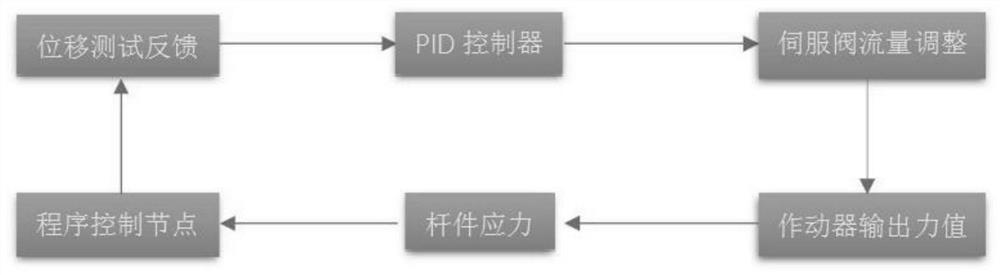

[0040]When the steel rod 2 is loaded, when the stress sensor 10 on the steel rod 2 measures the maximum deformation of the steel rod 2, the controller program automatically starts the prestressing system, and when the displacement sensor 11 measures the feedback steel rod 2 reaches zero deformation Program control can stop applying prestress; it can also continue to apply prestress. When the sensor measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com