A kind of light-emitting diode and its preparation method

A technology of light-emitting diodes and light-emitting layers, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of low overlap rate of electron-hole wave functions and affect the luminous efficiency of light-emitting diodes, so as to improve luminous efficiency and improve electron-hole Effect of hole wave function overlap rate and reduction of migration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

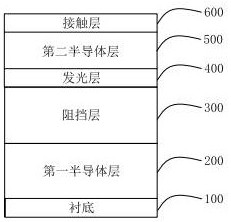

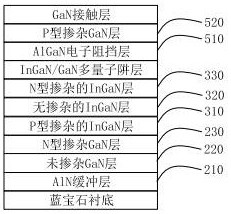

[0034] see Figure 1-Figure 2 , which is a light-emitting diode provided by the first embodiment of the present invention, the light-emitting diode includes a substrate 100; Layer 500 and contact layer 600; wherein, substrate 100, also known as substrate, is a substrate for epitaxial layer growth, used to support and fix the epitaxial layer, substrate 100 can be patterned or non-patterned flat substrate 100 , the characteristics matching between the substrate 100 and the epitaxial layer needs to be very strict, otherwise the growth quality of the epitaxial layer will be affected. At present, the industrialized substrate 100 of light-emitting diodes mainly includes sapphire (Al 2 O 3 ), SiC and Si, different substrate 100 materials, the growth, processing and packaging of light emitting diode structures require different techniques. In this embodiment, sapphire (Al 2 O 3 ) as the substrate 100, sapphire (Al 2 O 3 ) as the most widely used substrate 100 material for light...

Embodiment 2

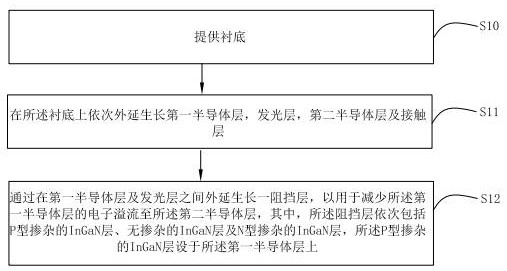

[0050] see image 3 , which shows a method for preparing a light-emitting diode according to the second embodiment of the present invention, and the method includes steps S10-S12:

[0051] Step S10, providing a substrate;

[0052] Among them, the substrate can be a patterned or non-patterned flat substrate, and the characteristics of the substrate and the epitaxial layer must be very strict. For example, lattice mismatch and thermal mismatch need to be matched to grow epitaxial layers with excellent quality. Otherwise, the growth quality of the epitaxial layer and the performance of the light-emitting diode will be directly affected. In this embodiment, the substrate is made of sapphire (Al 2 O 3 ) material, its chemical properties are stable, it does not absorb visible light, it is cheap and low in cost, and its production technology is mature and simple. It is the most widely used substrate material for light-emitting diodes.

[0053] Step S11, sequentially epitaxially g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com