Coal rock maceral enrichment method based on charged micro-nano bubble flotation

A micro-component, micro-nano technology, applied in flotation, solid separation and other directions, can solve the problems of the enrichment of difficult coal and rock components, the restriction of fine processing and quality transformation of coal resources, and the small difference of surface physical and chemical properties. , to achieve the effect of improving the efficiency of sorting and enrichment, fully separating and enriching, convenient and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

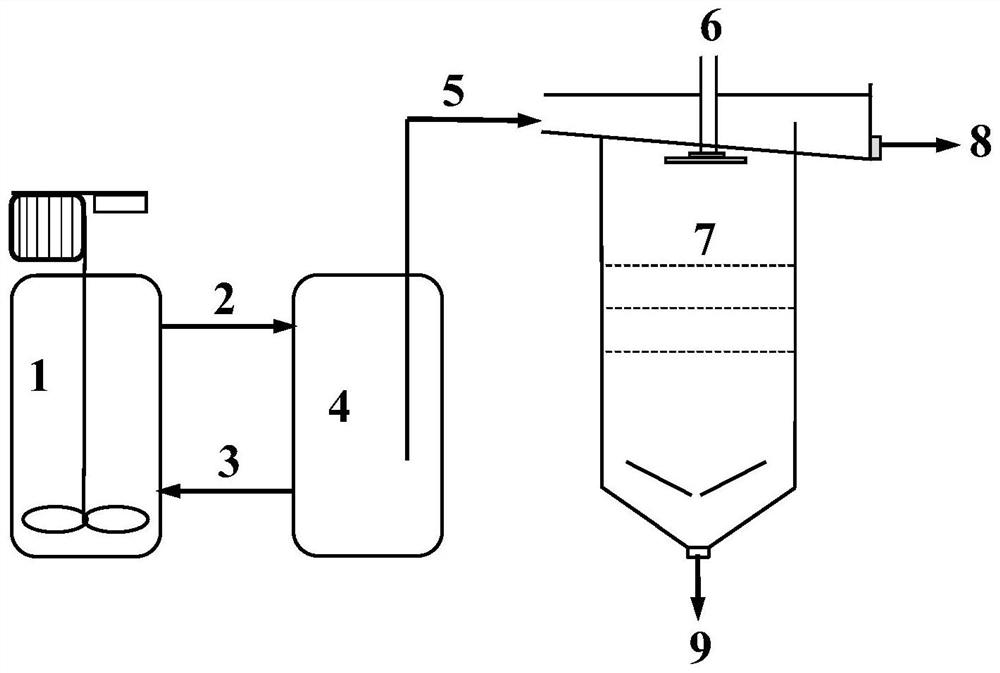

Method used

Image

Examples

Embodiment 1

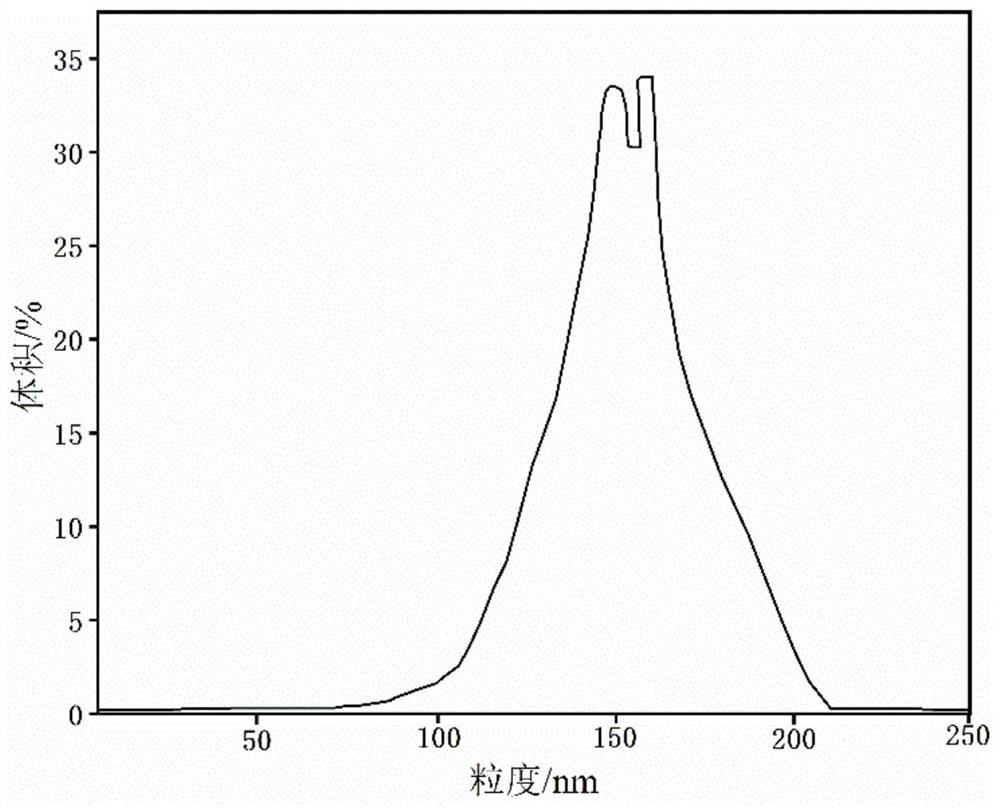

[0030] Select the anionic sodium lauryl sulfate solution that solution concentration is 0.25mM / L to prepare charged micro-nano bubbles (such as figure 2 Shown, the particle size of charged bubble is between 100-200nm), gets 400mL in order to flotation test, promptly charged micro-nano bubble solution accounts for pulp volume fraction is 40%, and inorganic salt ion aluminum chloride is 90mg, captures The dosage of kerosene as a absorbent is 2000g / t, and the dosage of 2-octanol as a foaming agent is 600g / t.

Embodiment 2

[0032] Example 2 is similar to Example 1, except that the concentration of sodium dodecyl sulfate solution for preparing charged micro-nano bubbles is 0.75 mM / L. The particle size of the prepared charged bubbles is between 100-200nm.

Embodiment 3

[0034] Example 3 is similar to Example 1, except that the concentration of sodium dodecyl sulfate solution for preparing charged micro-nano bubbles is 1.0 mM / L. The particle size of the prepared charged bubbles is between 100-200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com