Energy storage ceramic material for pulse capacitor and preparation method thereof

A technology of pulse capacitors and ceramic materials, which is applied in the field of ceramic materials, can solve the problems that the performance cannot meet the requirements of high-performance energy storage applications, and achieve the effects of good energy storage temperature stability, increased process complexity, and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

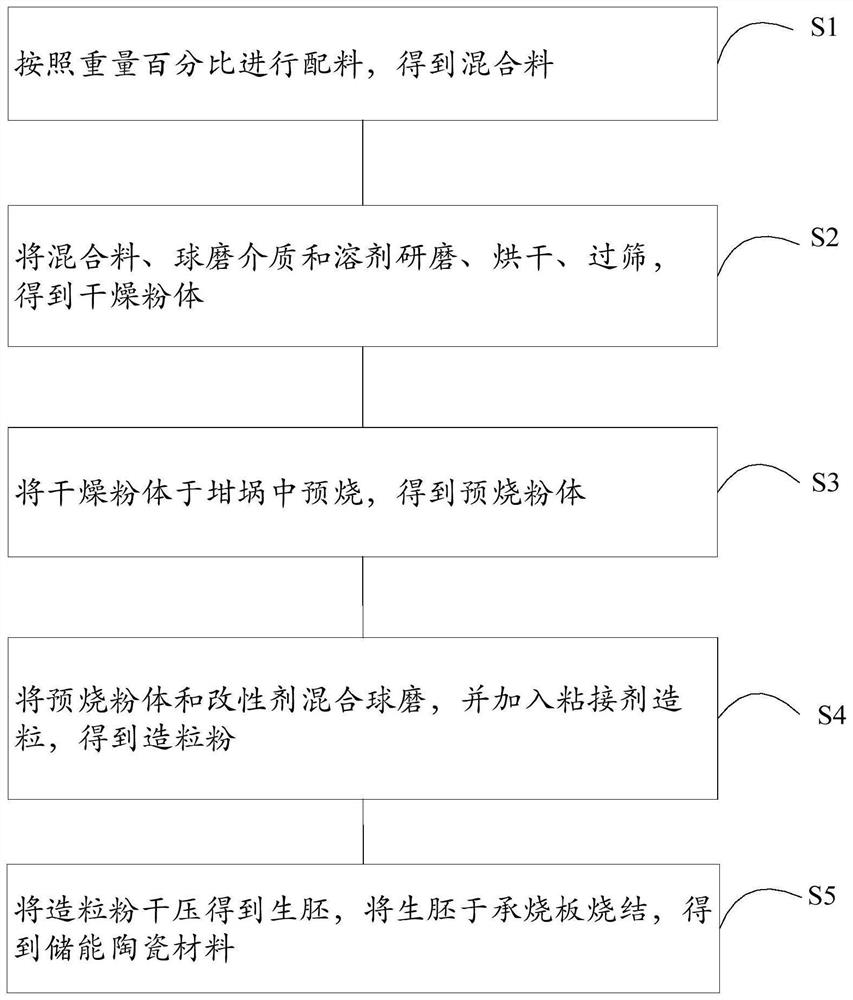

[0033] The embodiment of the present application provides an energy storage ceramic material for a pulse capacitor, and the energy storage ceramic material for a pulse capacitor is prepared by the following steps:

[0034] S1, the BaTiO 3 , SrCO 3 、 Bi 2 o 3 、TiO 2 and La 2 o 3 According to 69.78wt%, 13.65wt%, 5.98wt%, 10.24wt%, 0.35wt% weight percentages are carried out batching respectively, obtain compound;

[0035] S2. Using yttrium-stabilized zirconia balls as the ball milling medium and deionized water as the solvent, grind the obtained mixture for 6 hours according to the weight ratio of mixture: ball milling medium: solvent = 1:5:2. The slurry obtained after ball milling is Dry in a drying oven at 80°C for 24 hours, dry and pass through an 80-mesh sieve to obtain a dry powder;

[0036] S3. Place the dry powder in a crucible, pre-fire and keep it warm at 900° C. for 4 hours to obtain a pre-fire powder;

[0037] S4. Weigh 100g of calcined powder, and mix magnesia...

Embodiment 2

[0040] The embodiment of the present application provides an energy storage ceramic material for a pulse capacitor, and the energy storage ceramic material for a pulse capacitor is prepared by the following steps:

[0041]S1, the BaTiO 3 , SrCO 3 、 Bi 2 o 3 、TiO 2 and CeO 2 According to 69.78wt%, 13.65wt%, 5.98wt%, 10.24wt%, 0.37wt% by weight to carry out batching respectively, obtain compound;

[0042] S2. Using yttrium-stabilized zirconia balls as the ball milling medium and deionized water as the solvent, grind the obtained mixture for 6 hours according to the weight ratio of mixture: ball milling medium: solvent = 1:5:2. The slurry obtained after ball milling is Dry in a drying oven at 80°C for 24 hours, dry and pass through an 80-mesh sieve to obtain a dry powder;

[0043] S3. Place the dry powder in a crucible, pre-fire and keep it warm at 900° C. for 4 hours to obtain a pre-fire powder;

[0044] S4. Weigh 100g of calcined powder, mix with 0.80g of magnesium oxide...

Embodiment 3

[0047] The embodiment of the present application provides an energy storage ceramic material for a pulse capacitor, and the energy storage ceramic material for a pulse capacitor is prepared by the following steps:

[0048] S1, the BaTiO 3 , SrCO 3 、 Bi 2 o 3 、TiO 2 and Nd 2 o 3 According to the weight percentage of 69.78wt%, 13.65wt%, 5.98wt%, 10.24wt%, 0.36wt%, respectively, batching is carried out to obtain the mixture;

[0049] S2. Using yttrium-stabilized zirconia balls as the ball milling medium and deionized water as the solvent, grind the obtained mixture for 6 hours according to the weight ratio of mixture: ball milling medium: solvent = 1:5:2. The slurry obtained after ball milling is Dry in a drying oven at 80°C for 24 hours, dry and pass through an 80-mesh sieve to obtain a dry powder;

[0050] S3. Place the dry powder in a crucible, pre-fire and keep it warm at 900° C. for 4 hours to obtain a pre-fire powder;

[0051] S4. Weigh 100g of calcined powder, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com