Wide-temperature stable energy storage ceramic material and preparation method thereof

A ceramic material and a stable technology, which are applied in the field of wide temperature stable energy storage ceramic materials and their preparation, can solve the problems of low releasable energy density, insufficient temperature stability of BaTiO-based energy storage performance, and lack of pulse charge and discharge performance, and achieve The effect of good energy storage temperature stability, increased process complexity, and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

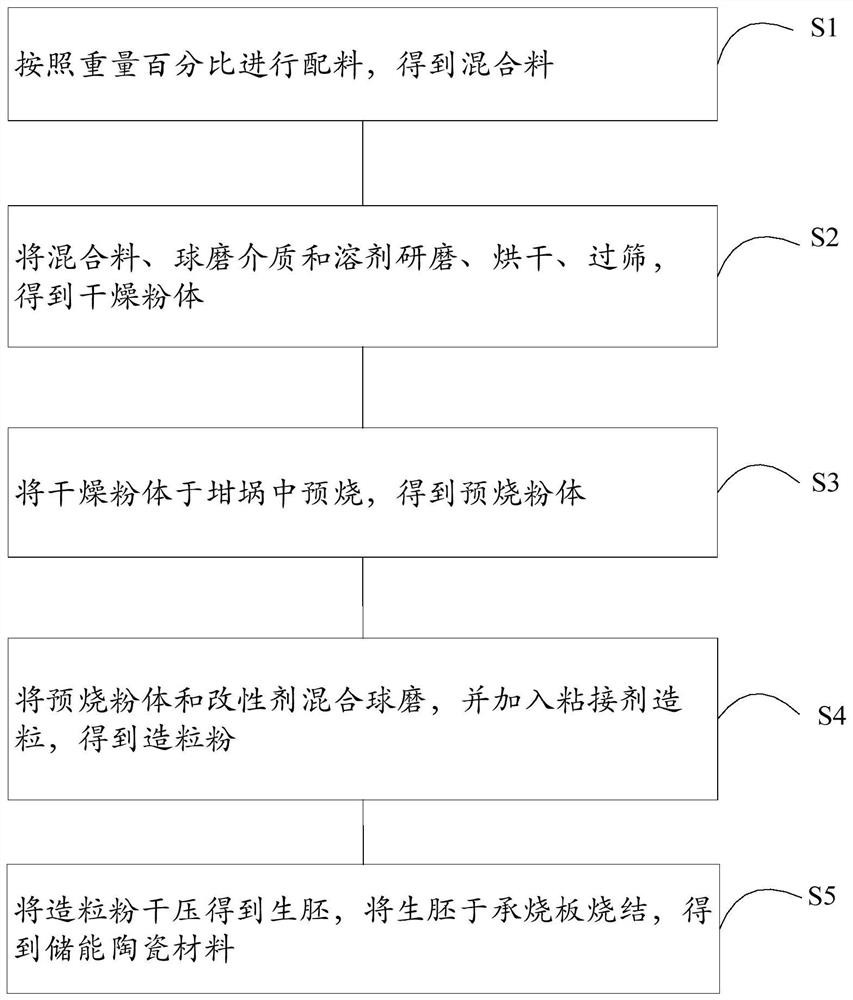

[0036] The preparation method of the wide temperature stable energy storage ceramic material described in this embodiment comprises the following steps:

[0037] S1: BaCO 3 、TiO 2 , SrCO 3 、 Bi 2 o 3 , MgO and Nb 2 o 5 According to the weight percentages of 68.1wt%, 28.9wt%, 1.2wt%, 1.7wt%, 0.05wt% and 0.08wt%, respectively, the compounded material is obtained;

[0038] S2: The mixture is milled with yttrium-stabilized zirconia balls as the ball milling medium, and deionized water is used as the solvent. According to the weight ratio of mixture: ball milling medium: solvent = 1:5:2, grind for 6 hours, dry and pass through an 80-mesh sieve After that, the mixture is obtained;

[0039] S3: The mixture is placed in a crucible, and pre-fired at 1000°C for 4 hours to obtain a pre-fired powder;

[0040] S4: Weigh 100g of calcined powder, mix with 0.05g of manganese carbonate and 1.0g of silicon dioxide, and ball mill for 6 hours, dry and pass through an 80-mesh sieve, mix wi...

Embodiment 2

[0043] The preparation method of the wide temperature stable energy storage ceramic material described in this embodiment comprises the following steps:

[0044] S1: BaCO 3 、TiO 2 , SrCO 3 、 Bi 2 o 3 , MgO and Nb 2 o 5 According to the weight percentages of 68.1wt%, 28.5wt%, 3.1wt%, 3.0wt%, 0.20wt% and 0.32wt%, the mixture is obtained;

[0045] S2: The mixture is milled with yttrium-stabilized zirconia balls as the ball milling medium, and deionized water is used as the solvent. According to the weight ratio of mixture: ball milling medium: solvent = 1:5:2, grind for 6 hours, dry and pass through an 80-mesh sieve After that, the mixture is obtained;

[0046] S3: The mixture is placed in a crucible, and pre-fired at 1000°C for 4 hours to obtain a pre-fired powder;

[0047] S4: Weigh 100g of calcined powder, mix with 0.1g of manganese carbonate and 0.5g of silicon dioxide, and ball mill for 6 hours, dry and pass through an 80-mesh sieve, mix with polyvinyl alcohol aqueou...

Embodiment 3

[0050] The preparation method of the wide temperature stable energy storage ceramic material described in this embodiment comprises the following steps:

[0051] S1: BaCO 3 、TiO 2 , SrCO 3 、 Bi 2 o 3 , MgO and Nb 2 o 5 According to the weight percentages of 61.5wt%, 28.4wt%, 4.7wt%, 4.6wt%, 0.30wt% and 0.49wt%, respectively, the compounded material is obtained;

[0052] S2: The mixture is milled with yttrium-stabilized zirconia balls as the ball milling medium, and deionized water is used as the solvent. According to the weight ratio of mixture: ball milling medium: solvent = 1:5:2, grind for 6 hours, dry and pass through an 80-mesh sieve After that, the mixture is obtained;

[0053] S3: The mixture is placed in a crucible, and pre-fired at 1000°C for 4 hours to obtain a pre-fired powder;

[0054] S4: Weigh 100g of calcined powder, mix with 0.05g of manganese carbonate and 1.0g of silicon dioxide, and ball mill for 6 hours, dry and pass through an 80-mesh sieve, mix wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com