Coal water slurry additive and preparation method thereof

An additive and coal-water slurry technology, which is applied in the fields of fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of poor stability and easy precipitation, inconsiderate changes in coal quality and stability, and increased viscosity, and achieves a solution to the problem. Poor stability, improving molecular structure characteristics and coal-water interfacial tension, improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

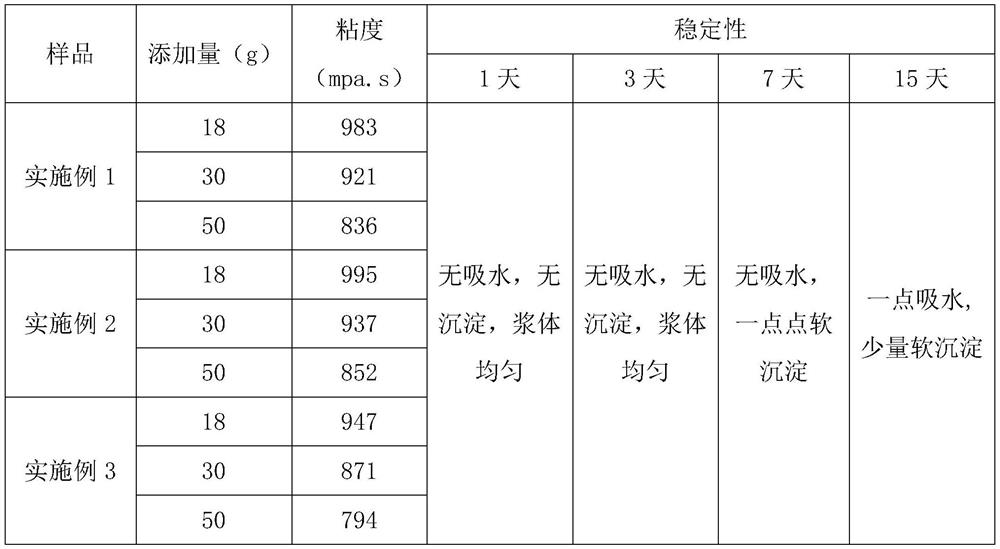

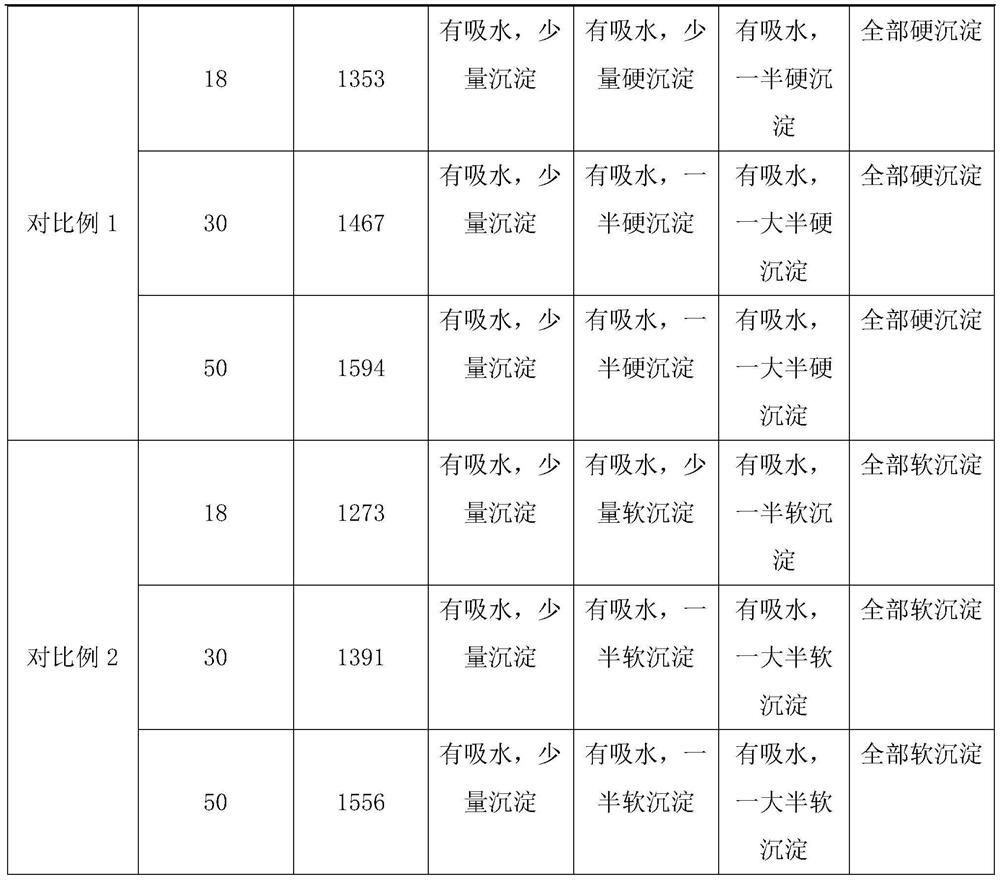

Embodiment 1

[0018] A coal water slurry additive comprises the following components in terms of mass percentage: 15% of aliphatic surfactant, 65% of naphthalene water reducer, 15% of complexing agent and 5% of inorganic base.

[0019] The aliphatic surfactant is alkali lignin; the naphthalene water reducer is sodium methylene dinaphthalene sulfonate; the complexing agent is sodium tripolyphosphate; and the inorganic base is sodium hydroxide.

[0020] The preparation method of the coal-water slurry additive comprises the following steps: weighing the raw materials of each component according to the proportion and mixing them uniformly to obtain the coal-water slurry additive.

Embodiment 2

[0022] A coal water slurry additive comprises the following components in terms of mass percentage: 20% of aliphatic surfactant, 50% of naphthalene water reducer, 20% of complexing agent and 10% of inorganic base.

[0023] The aliphatic surfactant is alkali lignin; the naphthalene-based water reducer is β-naphthalenesulfonate formaldehyde condensate (HSN naphthalene-based high-efficiency water-reducer produced by Qingdao Hongxia Polymer Materials Co., Ltd.) ; The complexing agent is trisodium phosphate; The inorganic base is potassium hydroxide.

[0024] The preparation method of the coal-water slurry additive comprises the following steps: weighing the raw materials of each component according to the proportion and mixing them uniformly to obtain the coal-water slurry additive.

Embodiment 3

[0026] A coal-water slurry additive comprises the following components in terms of mass percentage: 30% of aliphatic surfactant, 65% of naphthalene-based water reducer, and 5% of inorganic base.

[0027] The aliphatic surfactant is alkali lignin; the naphthalene water reducer is sodium methylene dinaphthalene sulfonate; the complexing agent is sodium tripolyphosphate; and the inorganic base is sodium carbonate.

[0028] The preparation method of the coal-water slurry additive comprises the following steps: weighing the raw materials of each component according to the proportion and mixing them uniformly to obtain the coal-water slurry additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com