Preparation method of high-toughness heat-treatment-free material suitable for castings with various wall thicknesses

A heat treatment-free, casting technology, applied in the field of aluminum alloy materials, can solve the problem that the mechanical properties are greatly affected by the wall thickness, and achieve the effects of reducing the phenomenon of agglomeration, improving the overall comprehensive mechanical properties, and enhancing the refinement effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

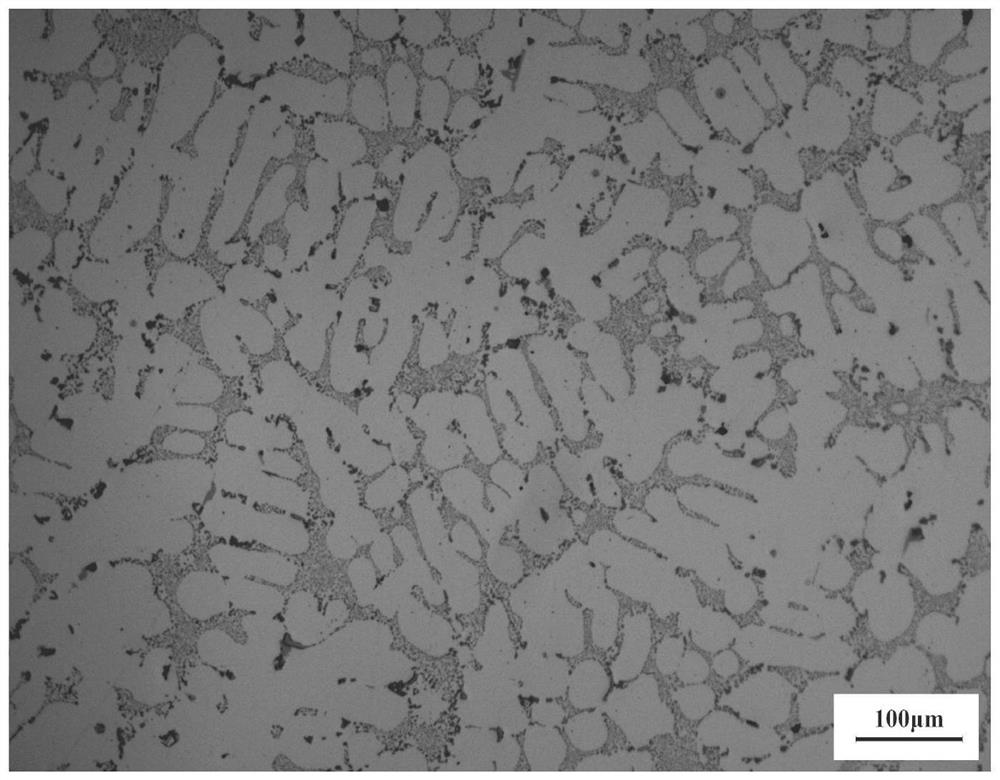

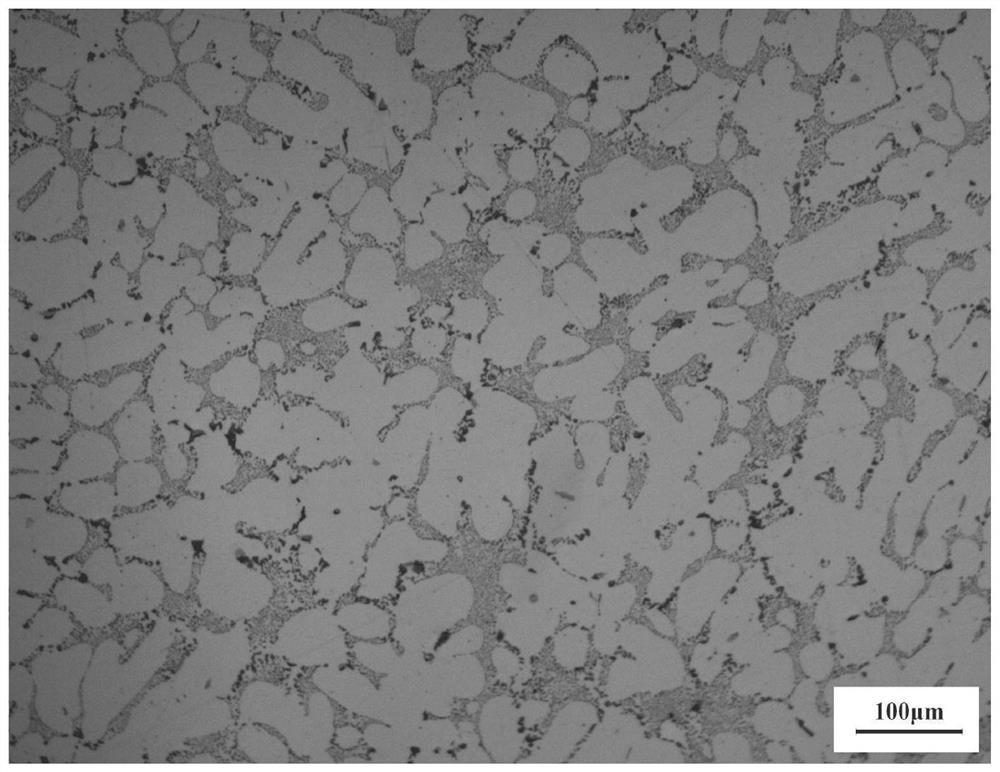

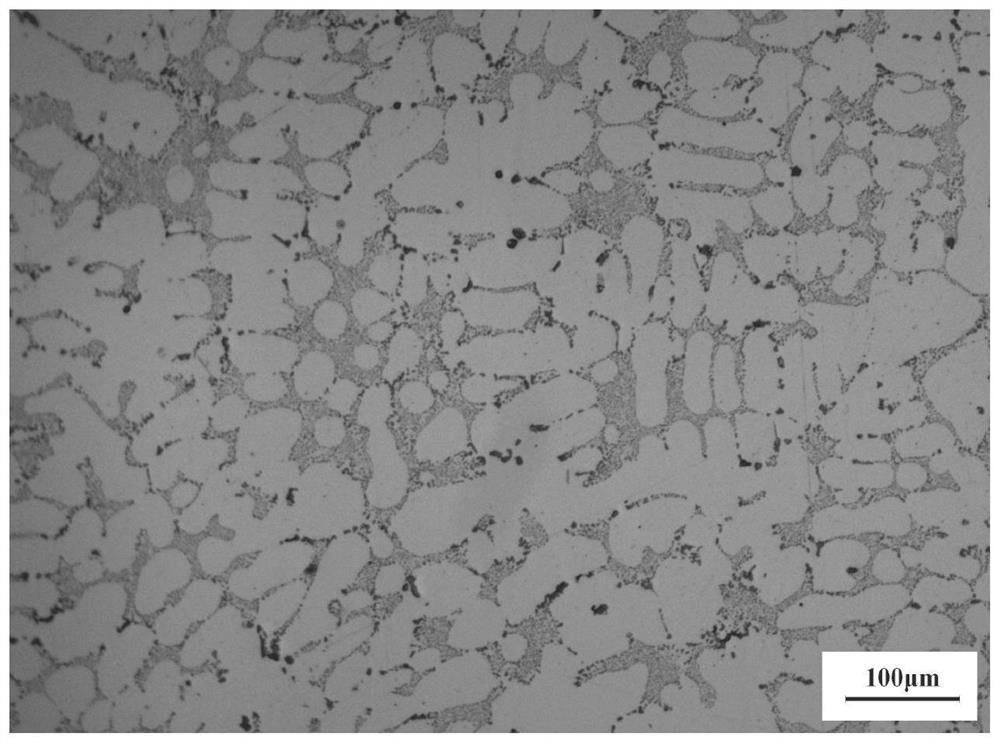

Image

Examples

Embodiment 1

[0027] Weigh 13110kg of aluminum ingots for remelting, 975kg of industrial silicon, 300kg of aluminum-titanium-boron master alloy (AlTi5B1), 60kg of metal magnesium, 30kg of aluminum-strontium master alloy (AlSr10), 90kg of electrolytic manganese, 30kg of aluminum-niobium master alloy (AlNb50), 30kg of aluminum Chromium master alloy (AlCr10) 150kg, aluminum lanthanum master alloy (AlLa10) 150kg, aluminum cerium (AlCe10) master alloy 105kg, 15 tons in total.

[0028] A method for preparing a high-strength and tough heat-free material suitable for castings with various wall thicknesses, the steps are as follows:

[0029] (1) Put aluminum ingots and industrial silicon for remelting into a flame-type reverberatory furnace, ignite natural gas for melting, and after all the materials are melted, adjust the temperature of the molten aluminum to 720°C, add aluminum-niobium master alloy, and electrolytic manganese.

[0030] (2) Use a stirring rake to stir the aluminum alloy liquid for ...

Embodiment 2

[0037] Weigh 25530kg of aluminum ingots for remelting, 2250kg of industrial silicon, 750kg of aluminum-titanium-boron master alloy (AlTi5B1), 135kg of metal magnesium, 60kg of aluminum-strontium master alloy (AlSr10), 225kg of electrolytic manganese, 90kg of aluminum-niobium master alloy (AlNb50), 90kg of aluminum Chromium master alloy (AlCr10) 450kg, aluminum lanthanum master alloy (AlLa10) 300kg, aluminum cerium (AlCe10) master alloy 210kg, 30 tons in total.

[0038] A method for preparing a high-strength and tough heat-free material suitable for castings with various wall thicknesses, the steps are as follows:

[0039] (1) Put aluminum ingots and industrial silicon for remelting into a flame-type reverberatory furnace, ignite natural gas for melting, and after all the materials are melted, adjust the temperature of the molten aluminum to 730°C, add aluminum-niobium master alloy, and electrolytic manganese.

[0040] (2) Use a stirring rake to stir the aluminum alloy liquid f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com