Vacuum low-pressure carburizing process for shaft gear parts

A vacuum low-pressure carburizing and process technology, applied in metal material coating process, furnace type, manufacturing tools, etc., can solve problems such as large deformation of keyway and tooth shape, eliminate machining stress, improve surface carburizing effect, The effect of reducing the amount of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

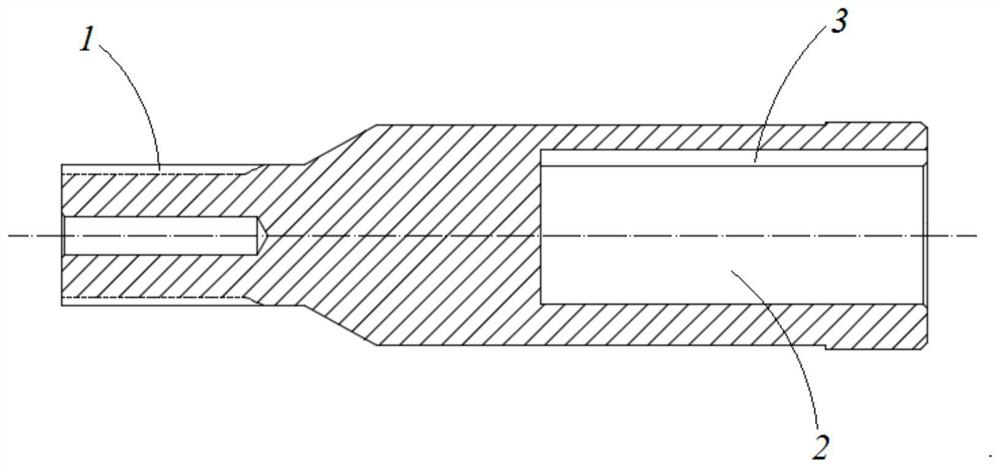

[0046] by figure 1 Take the input shaft gear part of an industrial robot reducer as an example. The material of the shaft gear part is SCM420H alloy steel. The technical requirements for heat treatment are: the effective hardened layer depth (PCD 550HV) of the carburized layer is 0.425-0.775mm, and the surface hardness It is 80.1~82.5HRA, and the tooth shape distortion is 0.015~0.025mm.

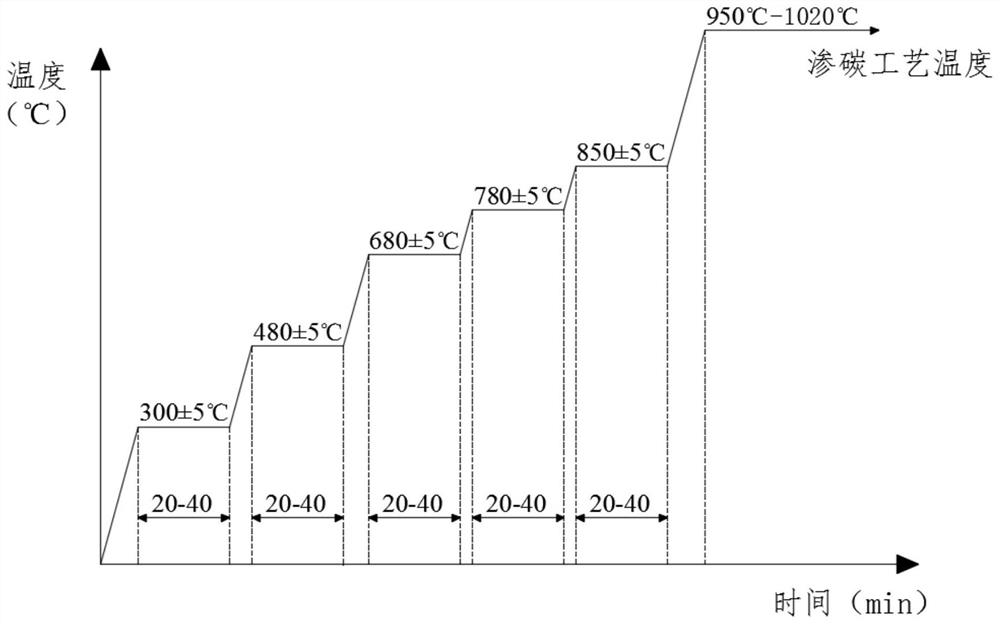

[0047] In order to meet the above-mentioned heat treatment technical requirements, a vacuum low-pressure carburizing process for shaft and tooth parts in this embodiment includes a heating stage, a carburizing stage and a quenching stage in sequence. In the heating stage, the workpiece is framed and placed in the furnace, using figure 2In the stepped heating and heat preservation process shown, the vacuum in the furnace is controlled below 1Pa, and the workpiece is heated up to 300±5°C, and the temperature is averaged for 20 minutes; the temperature is raised to 480±5°C, and the temperature...

Embodiment 2

[0051] A vacuum low-pressure carburizing process for shaft-tooth parts in this embodiment also uses figure 1 The input shaft gear part of an industrial robot reducer shown as an example, its basic process flow is the same as that of Embodiment 1, the difference lies in:

[0052] In the heating stage, the vacuum degree in the furnace is controlled below 1Pa, and the workpiece is heated up to 300±5°C, and the temperature is averaged for 40 minutes; the temperature is raised to 480±5°C, and the temperature is averaged for 40 minutes; To 780±5°C, average temperature for 40 minutes; heat up to 850±5°C, average temperature for 40 minutes; heat up to 960°C, reach the carburizing process temperature, and enter the carburizing stage.

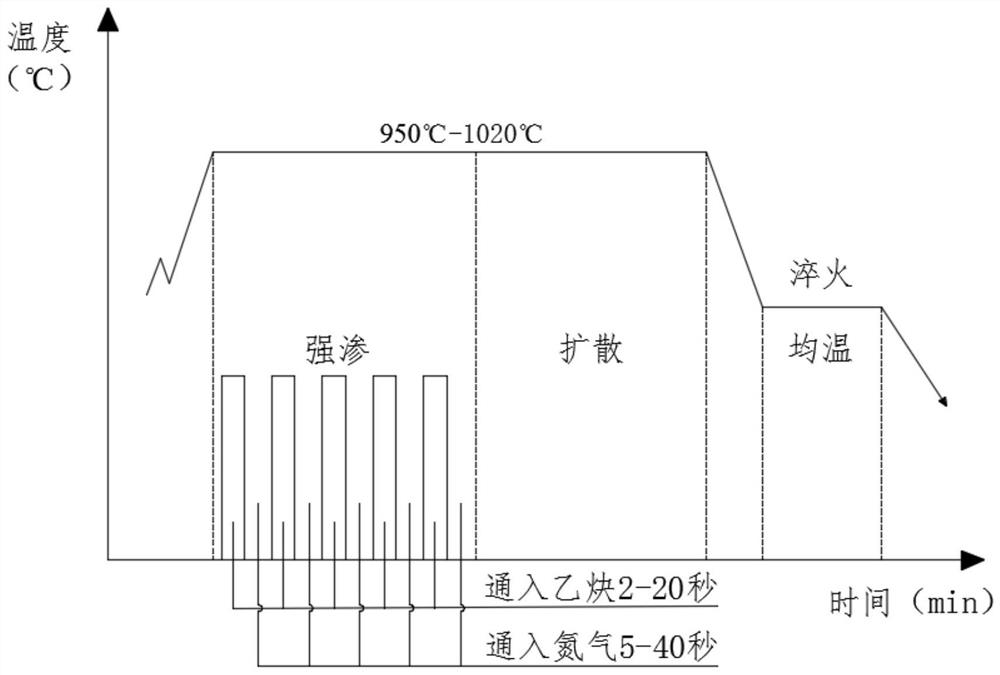

[0053] In the carburizing stage, the furnace pressure is controlled at 820-850Pa. In the strong infiltration stage, the acetylene gas is passed in for 20 seconds, and then the nitrogen gas is passed in for 40 seconds, which is a carburizing pulse cycle. ...

Embodiment 3

[0056] A vacuum low-pressure carburizing process for shaft-tooth parts in this embodiment also uses figure 1 The input shaft gear part of an industrial robot reducer shown as an example, its basic process flow is the same as that of Embodiment 1, the difference lies in:

[0057] In the heating stage, the vacuum degree in the furnace is controlled below 1Pa, and the workpiece is heated up to 300±5°C, and the temperature is averaged for 30 minutes; the temperature is raised to 480±5°C, and the temperature is averaged for 30 minutes; To 780±5°C, average temperature for 30 minutes; heat up to 850±5°C, average temperature for 30 minutes; heat up to 950°C, reach the carburizing process temperature, and enter the carburizing stage.

[0058] In the carburizing stage, the furnace pressure is controlled at 850-880Pa. In the strong infiltration stage, acetylene gas is introduced for 10 seconds, and then nitrogen gas is passed in for 20 seconds, which is a carburizing pulse cycle. The ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com