Uniformly-distributed three-dimensional lithium alloy negative electrode and preparation method thereof

A uniform distribution and lithium alloy technology, applied in battery electrodes, lithium batteries, electrical components, etc., can solve the problem of not meeting the safety performance and electrochemical cycle performance of high energy density batteries, the loss of active positive electrode active materials, and the lack of high reactivity. Good and other problems, to achieve the effect of reducing the volume expansion effect, improving the problem of lithium dendrites, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

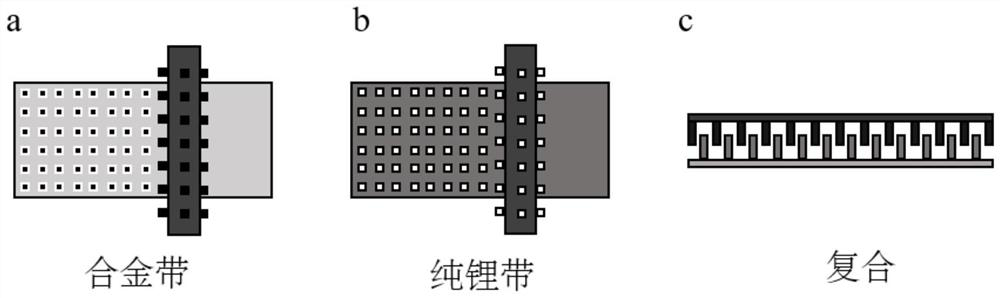

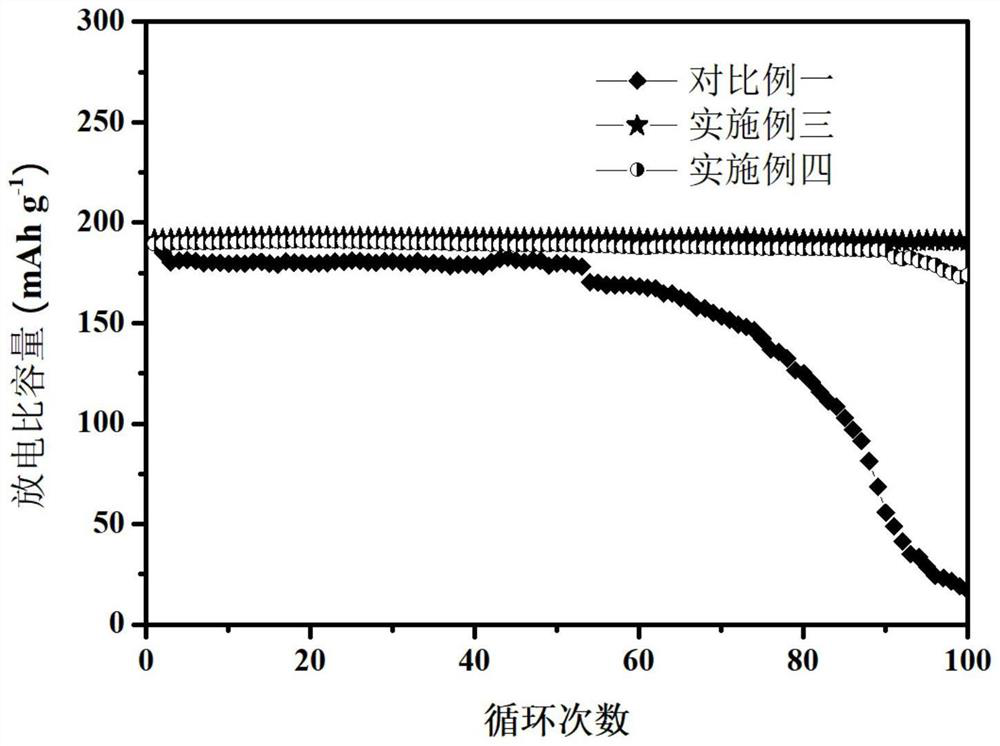

Embodiment 1

[0020] First, Li and Al are treated at a high temperature at 400°C under an inert gas at an atomic ratio of 9:4; to obtain Al 4 Li 9 Alloy material, 50 micron lithium aluminum alloy strip is obtained by rolling, and the surface roughness treatment is carried out to form uniformly distributed convex parts; the 50 micron pure lithium strip is surface treated to obtain grooves, and then the two are processed Composite rolling to form a composite strip. After vacuum heat treatment at 100° C. for 6 hours, the final lithium alloy negative electrode ribbon material was obtained. The negative electrode sheet of the button battery was obtained by a slicing machine, and LiNi 0.8 co 0.1 mn 0.1 o 2 The positive electrode sheet was assembled into a 2032 button cell using EC:DEC:DMC=1:1:1 as the electrolyte, and then the electrochemical performance test was carried out. Test results such as figure 2 shown.

Embodiment 2

[0022] First, Li and Ca are treated at high temperature under inert gas at 300°C in an atomic ratio of 2:1; CaLi 2 Alloy material, 50 micron lithium-calcium alloy strip is obtained by rolling, and the surface roughness treatment is carried out to form uniformly distributed convex parts; the 50 micron pure lithium strip is surface treated to obtain grooves, and then the two are processed Composite rolling to form a composite strip. After vacuum heat treatment at 100° C. for 6 hours, the final lithium alloy negative electrode ribbon material was obtained. The negative electrode sheet of the button battery was obtained by a slicing machine, and LiNi 0.8 co 0.1 mn 0.1 o 2 The positive electrode sheet was assembled into a 2032 button cell using EC:DEC:DMC=1:1:1 as the electrolyte, and then the electrochemical performance test was carried out. Test results such as figure 2 shown.

Embodiment 3

[0024] First, Li and Mg are treated at a high temperature at 500°C under an inert gas at an atomic ratio of 8:2; LiMg solid solution alloy material is obtained, and a 50-micron lithium-magnesium alloy strip is obtained by rolling and surface roughness treatment. Uniformly distributed convex parts; 50 micron pure lithium strip is surface treated to obtain grooves, and then the two are combined and rolled to form a composite strip. After vacuum heat treatment at 100° C. for 6 hours, the final lithium alloy negative electrode ribbon material was obtained. The negative electrode sheet of the button battery was obtained by a slicing machine, and LiNi 0.8 co 0.1 mn 0.1 o 2 The positive electrode sheet was assembled into a 2032 button cell using EC:DEC:DMC=1:1:1 as the electrolyte, and then the electrochemical performance test was carried out. Test results such as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com