Suaeda glauca tea rolling machine technology

A process, Suaeda salsa technology, applied in the field of Suaeda salsa rolling tea machine technology, can solve the problems of insufficient filling, affecting product quality, etc., to achieve the effect of improving reliability, ensuring product quality, and meeting process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

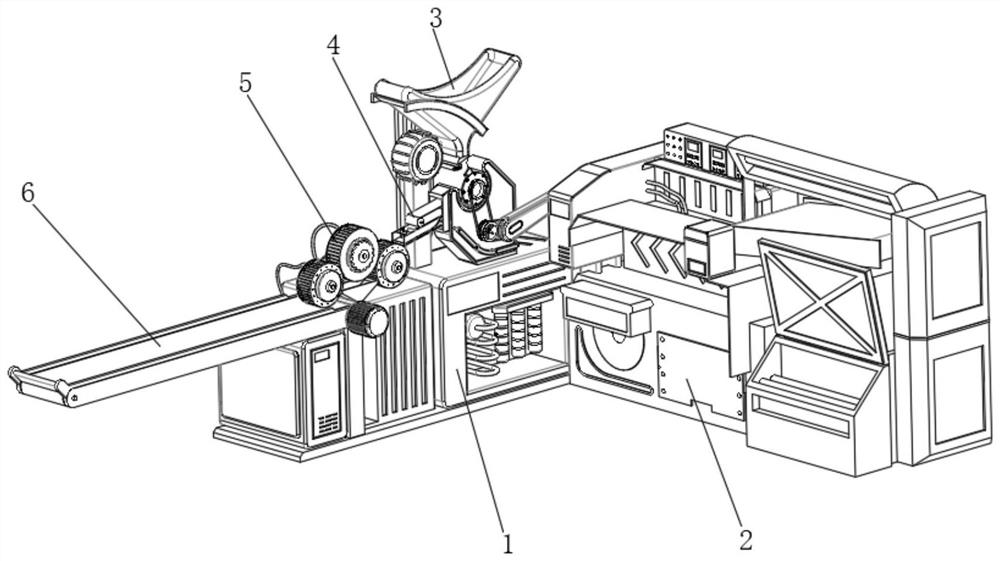

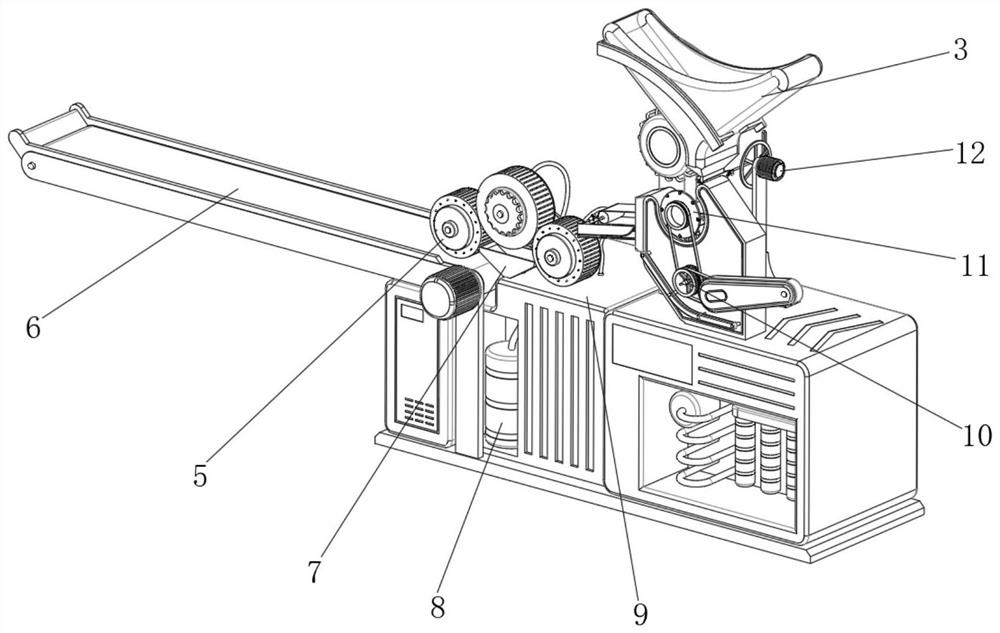

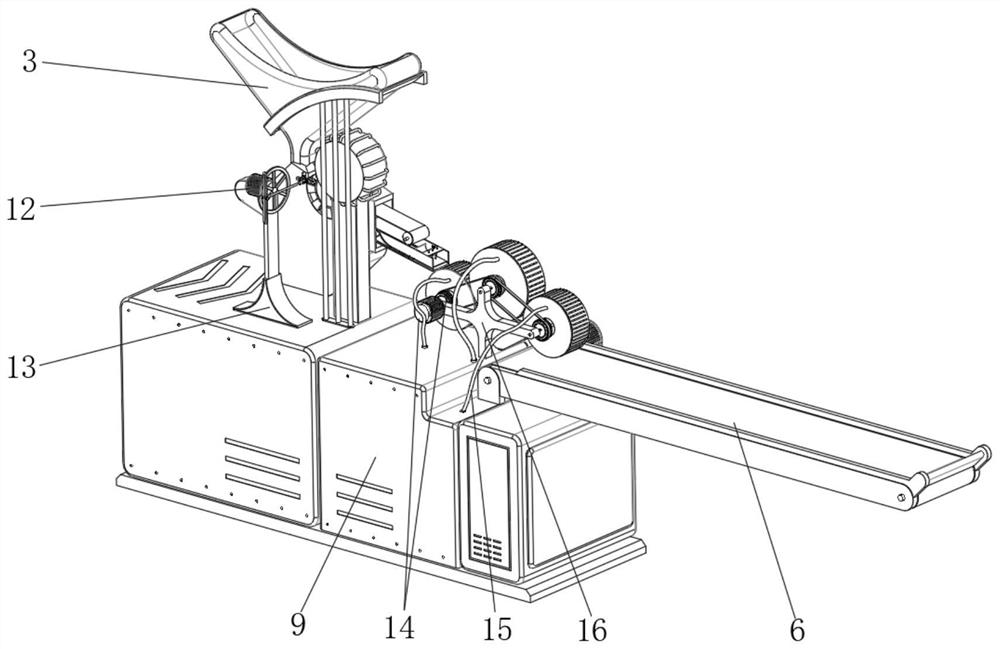

[0065] A Suaeda salsa tea rolling machine, the overall function is consistent with the cigarette rolling machine, and the tea leaves are processed into tea rolls instead of tobacco leaves, such as Figure 1-11 As shown, it includes tea rolling equipment 1 and rolling equipment 2. The rolling equipment 2 is used to process the rolling tea paper into a roll structure, which is beneficial to the filling of subsequent tea leaves; the rolling tea equipment 1 is used for rolling tea The tea rolling paper is stuffed with tea leaves and finally prepared into tea rolls. The content of the present invention mainly lies in the improvement of the stuffing step, the conveying step and the sorting step. For other specific structures not mentioned, refer to existing cigarette rolling machines on the market; The tea rolling equipment 1 is arranged on one side of the output end of the rolling equipment 2. A hopper 3 is installed on the tea rolling equipment 1. A tea plugging mechanism is arrang...

Embodiment 2

[0071] A kind of Suaeda salsa rolling tea machine, such as figure 2 As shown, in order to improve environmental protection; this embodiment makes the following improvements on the basis of embodiment 1: the tea rolling equipment 1 is also provided with a slag collection mechanism, which includes a receiving bucket 7 and a receiving box 8, The receiving bucket 7 is located at the bottom of the hollow drum 17, and the bottom of the receiving bucket 7 is connected to the top of the receiving box 8 through a connecting pipe; by setting the receiving bucket 7 and the receiving box 8, the tea roll finishing mechanism 5 can be dropped during transportation The slag is collected and processed, which improves the environmental protection.

[0072] In order to facilitate subsequent transportation, such as figure 1 , figure 2 As shown, the tea rolling equipment 1 is also equipped with a discharge conveyor belt 6, one end of the discharge conveyor belt 6 is located directly below the ...

Embodiment 3

[0074] A kind of Suaeda salsa rolling tea machine, such as Figure 12-14 As shown, in order to improve environmental protection; this embodiment makes the following improvements on the basis of embodiment 2: a shredding mechanism is installed above the hopper 3 through a third support frame 46, and the shredding mechanism includes a shredding chamber 47 and a shredding motor 53, a sieve plate 55 is detachably installed in the shredding chamber 47, and the shredding motor 53 is installed on the outer wall of the bottom of the sieve plate 55, and a plurality of main cutters are installed on the output shaft of the shredding motor 53. Knife 54, the peripheral inner wall of shredding chamber 47 is equipped with the auxiliary cutter 52 that is adapted to main cutter 54, and main cutter 54 and auxiliary cutter 52 are arranged in a staggered distribution; By setting shredded chamber 47, shredded motor 53 and other structures, the materials used for producing tea rolls can be placed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com