Humic acid liquid fertilizer production system and production process

A production system and technology of humic acid, applied in mixers, dissolving, driving agitator dissolving, etc., can solve the problems of unstable product quality, product indicators, inability to guarantee consistent quality, and insoluble matter in finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

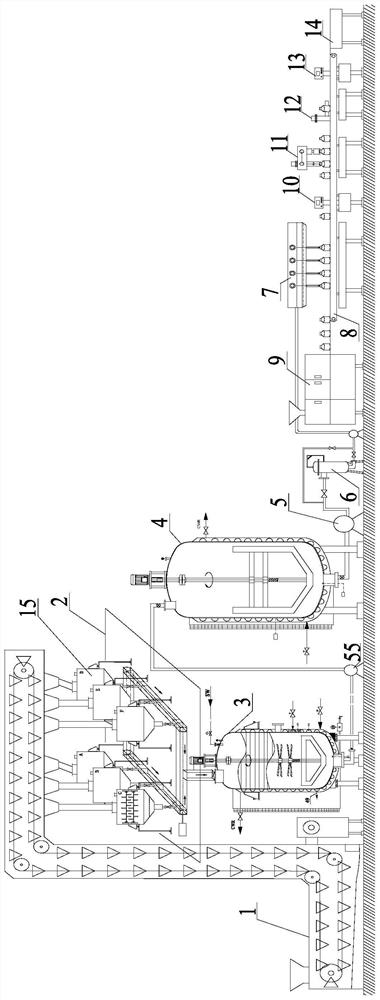

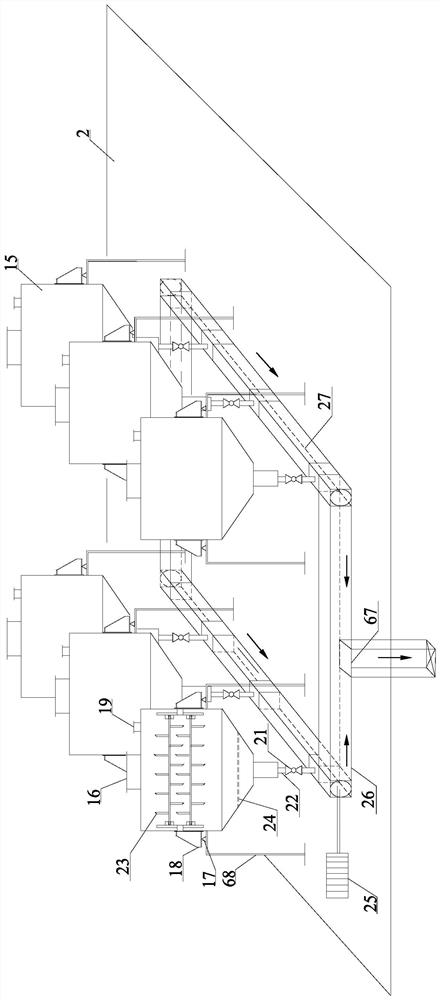

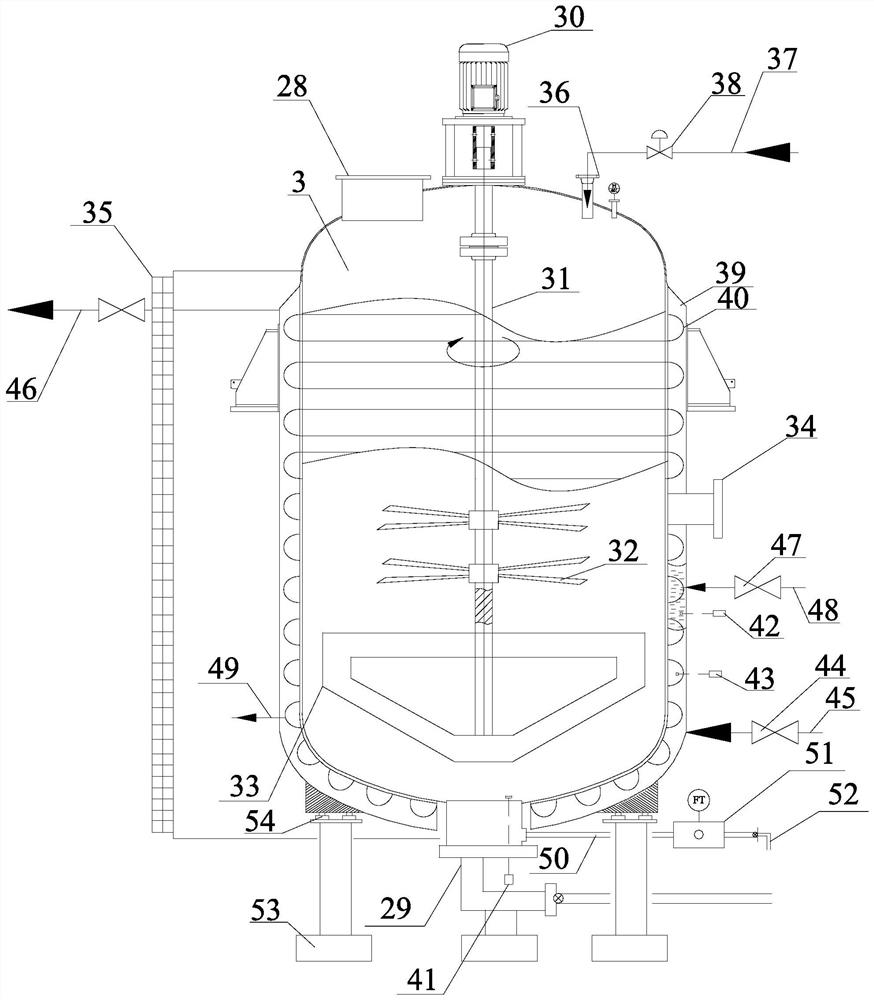

[0067] A humic acid liquid fertilizer production system, including a Z-type hoist 1 for loading various materials, the discharge end of the Z-type hoist 1 is connected to a material weighing and feeding unit through a discharge pipeline, and the material is weighed The outlet of the feeding unit is connected to at least one weight-increasing weighing batching tank through the discharge pipeline of the pipe chain conveying unit, and the outlet of the weight-increasing weighing batching tank 3 is connected to the product liquid storage tank 4 through the product delivery pipeline. The discharge end of the Z-type hoist 1 includes a plurality of discharge ports, and the plurality of discharge ports are respectively connected to the first storage tank 15 of the loss-in-weight weighing storage tank 15 in the corresponding material weighing feeding unit 2 through the discharge pipeline. A feed port 16 links to each other, and the material weighing feeding unit 2 includes several loss-...

Embodiment 2

[0080] A humic acid liquid fertilizer production system, including a Z-type hoist 1 for loading various materials, the discharge end of the Z-type hoist 1 is connected to a material weighing and feeding unit through a discharge pipeline, and the material is weighed The outlet of the feeding unit is connected to at least one weight-increasing weighing batching tank through the discharge pipeline of the pipe chain conveying unit, and the outlet of the weight-increasing weighing batching tank 3 is connected to the product liquid storage tank 4 through the product delivery pipeline. The discharge end of the Z-type hoist 1 includes a plurality of discharge ports, and the plurality of discharge ports are respectively connected to the first storage tank 15 of the loss-in-weight weighing storage tank 15 in the corresponding material weighing feeding unit 2 through the discharge pipeline. A feed port 16 links to each other, and the material weighing feeding unit 2 includes several loss-...

Embodiment 3

[0096]A humic acid liquid fertilizer production system, including a Z-type hoist 1 for loading various materials, the discharge end of the Z-type hoist 1 is connected to a material weighing and feeding unit through a discharge pipeline, and the material is weighed The outlet of the feeding unit is connected to at least one weight-increasing weighing batching tank through the discharge pipeline of the pipe chain conveying unit, and the outlet of the weight-increasing weighing batching tank 3 is connected to the product liquid storage tank 4 through the product delivery pipeline. The discharge end of the Z-type hoist 1 includes a plurality of discharge ports, and the plurality of discharge ports are respectively connected to the first storage tank 15 of the loss-in-weight weighing storage tank 15 in the corresponding material weighing feeding unit 2 through the discharge pipeline. A feed port 16 links to each other, and the material weighing feeding unit 2 includes several loss-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com