Timber intelligent optimization sawing system and sawing method

An intelligent optimization and wood technology, applied in the field of optimal sawing, can solve the problem of not optimizing the optimal cutting position, etc., and achieve the effects of simple structure, easy maintenance and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

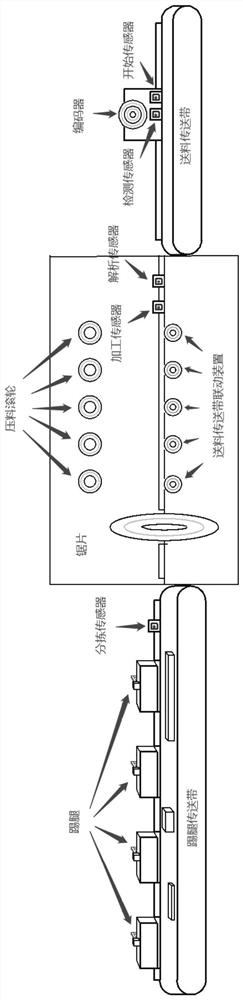

[0058] Such as figure 1As shown, a wood intelligent optimal sawing system includes a feeding conveyor belt for conveying wood, a wood detection mechanism is arranged on the feeding conveyor belt, a wood processing mechanism is arranged along the end of the feeding conveyor belt, and the wood processing mechanism The rear end is connected with a wood sorting mechanism; the feeding conveyor belt, the wood detection mechanism, the wood processing mechanism and the wood sorting mechanism are respectively connected to and controlled by an external central control system.

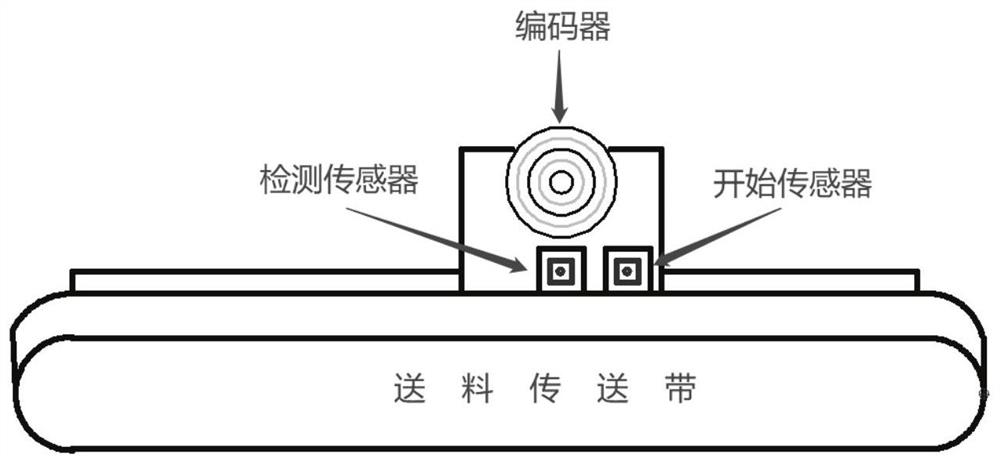

[0059] Such as image 3 As shown, the timber detection mechanism described in the present embodiment comprises:

[0060] start sensor, the start sensor is used to detect the incoming information of the wood;

[0061] A detection sensor, the detection sensor is arranged on the rear side of the start sensor, and is used to record the trigger information of the head, tail and fluorescent line of the wood;

[0062...

Embodiment 2

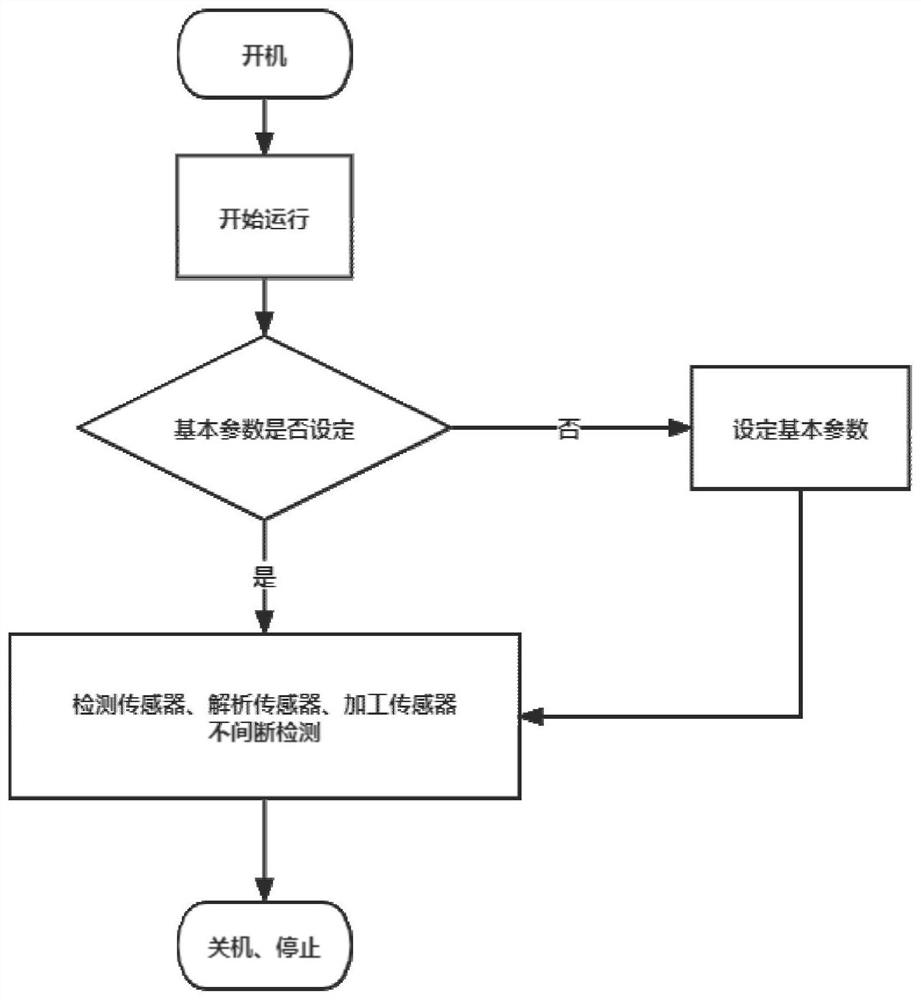

[0076] Such as figure 2 As shown, this embodiment also provides a sawing method of a wood intelligent optimization sawing system, including the following steps:

[0077] Step (1) Mark the wood with fluorescent lines in advance, and configure the wood formula; specifically, mark the defective parts of the wood with two fluorescent lines to limit the position, and when cutting, the section is inscribed;

[0078] The configuration of the wood formula specifically includes: dividing the wood into a main formula and a sub-recipe, the main formula includes the size of the main formula and the price of the main formula, and the sub-recipe includes the size range of the sub-recipe and the corresponding sub-recipe price; In this embodiment, the price of the main recipe is greater than the price of the sub-recipe, and due to the thickness of the saw blade, in order not to cause waste of good materials, the main recipe is cut using external cutting, and the sub-recipe is cut when cuttin...

Embodiment 3

[0084] Such as Figure 10 As shown, the default cutting method of wood during processing is external cutting of good materials and internal cutting of bad materials, and the error caused by the thickness of the saw blade will be taken into account. Generally, the wood is analyzed according to the situation of good material connected with bad material and bad material connected with good material by default, but this device also considers the situation of good material connected with good material and bad material connected with bad material, even any combination of good and bad materials under the critical value Case.

[0085] This system considers many extreme situations, assuming that the thickness of the saw blade is 4.5mm, the formula is as follows:

[0086] master recipe size master formula price Sub recipe minimum size Secondary formula maximum size Secondary formula unit price 100.0mm 100 yuan 20.0mm 50.0mm 0.1 yuan 200.0mm 300 yua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com