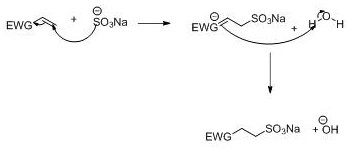

Sulfonating method of unsaturated alkane of electron withdrawing group

An electron-withdrawing group and unsaturated technology, which is applied in the field of sulfonation of unsaturated alkanes, can solve the problems of long time, increased production cost, and high reaction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Pyridine (39.5 g, 0.5 mol) was dissolved in 300 mL of water, and then sulfur dioxide was passed into the pyridine aqueous solution at 60 degrees Celsius, and the pH value was controlled between 6.0 and 6.2. In the case of continuous feeding of sulfur dioxide, the methyl acrylate (86.0 g, 1 mol) was slowly dropped into the reaction liquid system, and the pH value was controlled between 6.0 and 6.2, and the dropping time was 1 hour. At the end, the pH value was controlled between 6.0 and 6.2, and then kept for 1 hour. An aqueous solution of methyl sulfonate propionate was obtained, and after evaporating the water to dryness, 149.6 g (0.89 mol) of crystals of methyl sulfonate propionate were obtained, with a yield of 89%.

Embodiment 2

[0030] Pyridine (39.5 g, 0.5 mol) was dissolved in 300 mL of water, and then sulfur dioxide was passed into the pyridine aqueous solution at 50 degrees Celsius, and the pH value was controlled between 6.0 and 6.2. In the case of continuous feeding of sulfur dioxide, methyl acrylate (86.0 g, 1 mol) was slowly dropped into the reaction liquid system, and the pH value was controlled between 6.0 and 6.2, and the dropping time was 1 hour. At the end, the pH value was controlled between 6.0 and 6.2, and then kept for 1 hour. An aqueous solution of methyl sulfopropionate was obtained, and after evaporating the water to dryness, 141.3 g (0.84 mol) of methyl sulfopropionate crystals were obtained, with a yield of 84%.

Embodiment 3

[0032] Pyridine (39.5 g, 0.5 mol) was dissolved in 300 mL of water, and then sulfur dioxide was introduced into the aqueous ammonia solution at 60 degrees Celsius to control the pH value between 8.0 and 8.5. (86.0 g, 1 mol) was slowly dropped into the reaction liquid system, and the pH value was controlled between 8.0 and 8.5, and the dropping time was 1 hour. At the end, the pH value was controlled between 8.0 and 8.5, and then kept for 1 hour. An aqueous solution of methyl sulfonate propionate was obtained, and the water was evaporated to dryness to obtain 154.7 g (0.92 mol) of propyl methyl sulfonate crystals, with a yield of 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com