Reflective heat-insulation building coating system

A technology of architectural coatings and systems, applied in the direction of reflection/signal coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor batch stability, wide distribution of white sand particle size, rough surface, etc., to improve adhesion and uniformity High performance, excellent reflection and heat insulation function, and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

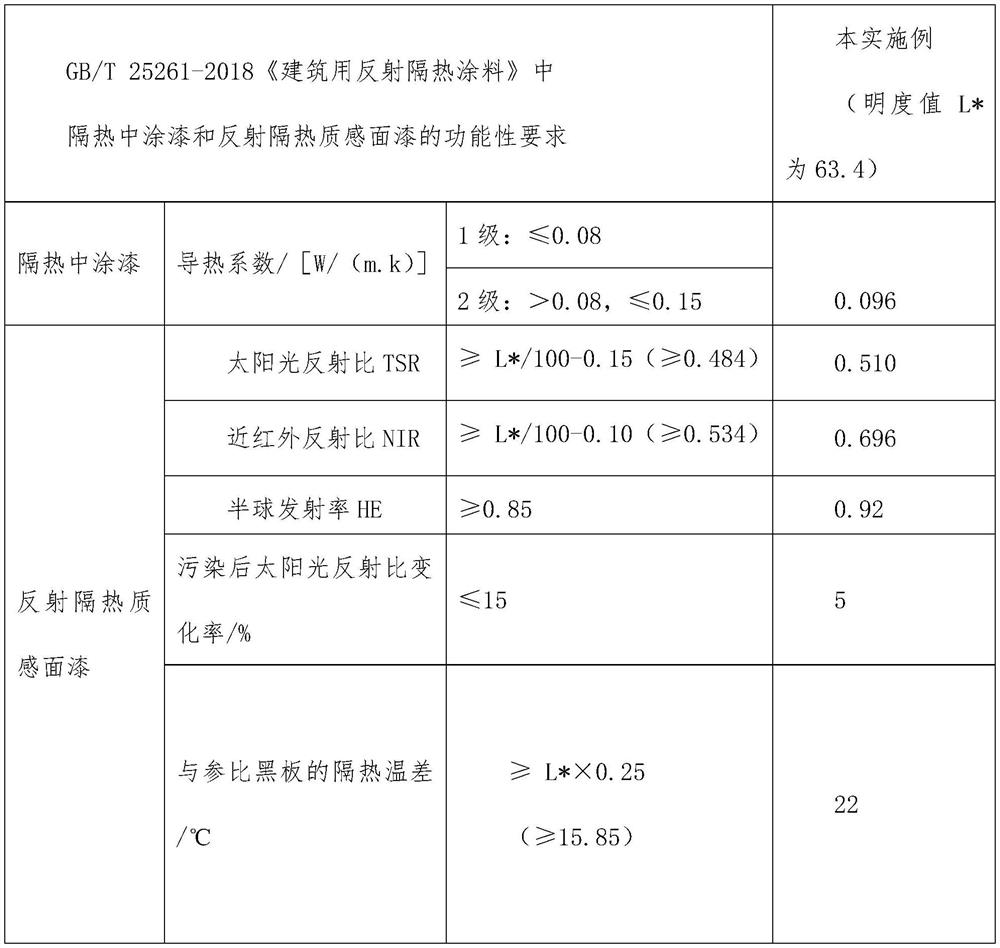

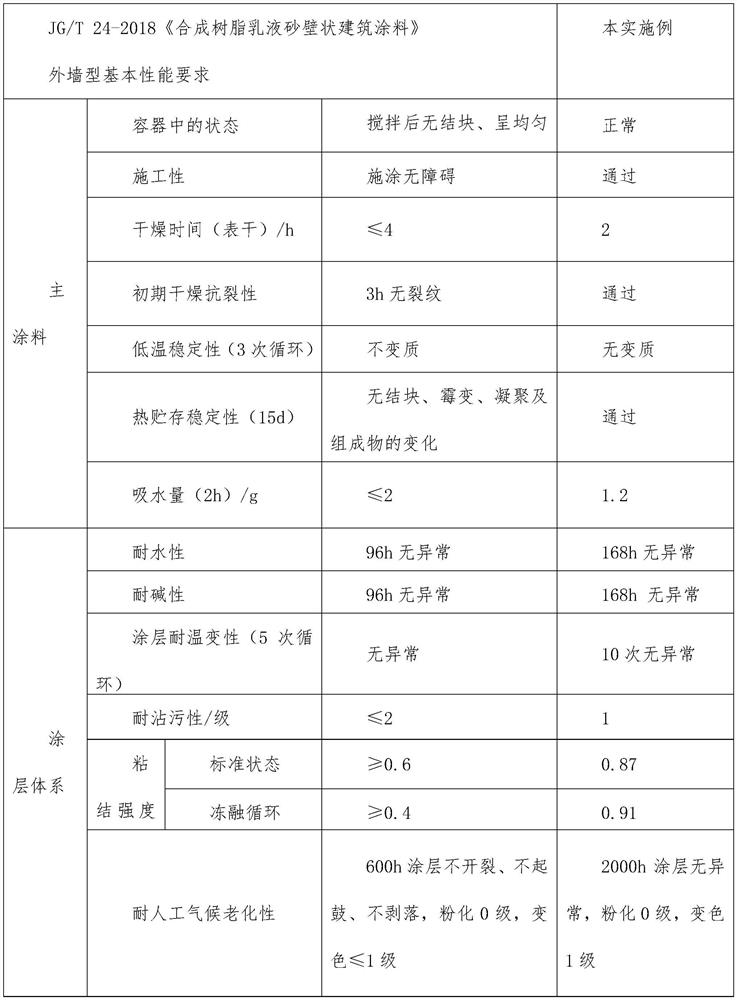

Embodiment 1

[0037] A reflective and heat-insulating architectural coating system provided in this embodiment includes reflective, heat-insulating, anti-alkali, and same-color coatings arranged in sequence from the inside to the outside (the side close to the building's exterior wall is the inside, and the side away from the building's exterior wall is the outside). Primer, reflective thermal insulation stone-like finish, and water-based stain-resistant finish varnish.

[0038] Reflective heat insulation stone-like topcoat includes the following raw materials in parts by mass:

[0039]25 parts of silicone acrylic emulsion, 7 parts of reflective heat insulation emulsion, 45 parts of light reflective heat insulation colored sand, 2 parts of film-forming aid, 18.3 parts of deionized water.

[0040] Among them, 45 parts of light reflective heat-insulating colored sand are divided into parts by mass: 2 parts are light yellow 20-30 mesh light-weight reflective heat-insulating colored sand, 5 par...

Embodiment 2

[0192] The difference between this embodiment and the first embodiment is that the first embodiment adopts real stone paint spray gun for spraying construction, and the second embodiment uses a batch knife for batch scraping construction.

[0193] Reflective heat insulation stone-like topcoat includes the following raw materials in parts by mass:

[0194] 26 parts of silicone acrylic emulsion, 5 parts of reflective thermal insulation emulsion, 45 parts of light reflective thermal insulation colored sand, 3 parts of film-forming aid, 18.3 parts of deionized water.

[0195] Among them, 35 parts of light reflective thermal insulation colored sand are divided into parts by mass: 20 parts are light yellow 20-30 mesh light reflective thermal insulation colored sand, 25 parts are brownish red 30-40 mesh light Reflective heat insulation and heat preservation colored sand. The solid content of the reflective thermal insulation emulsion is 43%, and at a temperature of 27°C, the viscosi...

Embodiment 3

[0209] The difference between this embodiment and Embodiment 1 is:

[0210] Reflective heat insulation stone-like topcoat includes the following raw materials in parts by mass:

[0211] Silicone acrylic emulsion 28 parts, reflective heat insulation emulsion 10 parts, light reflective heat insulation color sand 40 parts, film-forming aid 2.2 parts, deionized water 16.7 parts.

[0212] Among them, 40 parts of light reflective heat-insulating colored sand are divided into parts by mass: 2 parts are brownish-red light reflective heat-insulating colored sand of 30-40 mesh, and 10 parts are medium-yellow light-weight colored sand of 40-80 mesh. Reflective thermal insulation colored sand, 28 parts are gray 80-120 mesh light reflective thermal insulation colored sand. The solid content of the reflective thermal insulation emulsion is 41%. At a temperature of 23°C, the viscosity is <500mpa.s, the minimum film-forming temperature is 8°C, the pH value is 7.5, and the density is 1.02g / ml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com