Adhesive film composition containing polystyrene microspheres as well as preparation method and application of adhesive film composition

A technology of polystyrene microspheres and compositions, which can be applied to films/sheets without carriers, film/sheet-like adhesives, adhesives, etc., can solve problems such as fading, and achieve high transmittance and excellent mechanical properties. and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

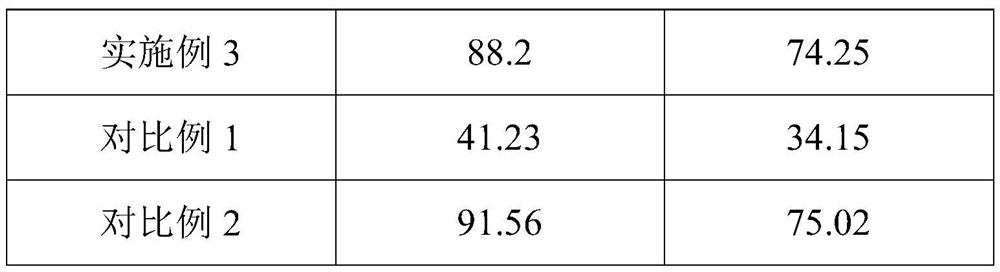

Examples

Embodiment 1

[0057] The present embodiment provides a film composition containing polystyrene microspheres, the film composition includes 94 parts of ethylene-vinyl acetate copolymer, 3 parts of polystyrene microspheres, 1 part of main gelatin in parts by weight. Linking agent, 1 part of auxiliary crosslinking agent, 0.5 part of silane coupling agent monomer, 0.1 part of silane coupling agent oligomer, 0.2 part of ultraviolet absorber and 0.2 part of other light stabilizers.

[0058] This embodiment provides a kind of adhesive film, described adhesive film comprises described adhesive film composition, and specific preparation method comprises:

[0059] According to the formulation amount, ethylene-vinyl acetate copolymer, polystyrene microspheres, main crosslinking agent, auxiliary crosslinking agent, silane coupling agent monomer, silane coupling agent oligomer, ultraviolet absorber and other light stabilizers Agents were mixed, and extrusion casting was carried out at a temperature of 8...

Embodiment 2

[0061] The present embodiment provides a film composition containing polystyrene microspheres, the film composition includes 80 parts of ethylene-vinyl acetate copolymer, 1 part of polystyrene microspheres, 0.2 part of main gelatin in parts by weight. Linking agent, 0.2 parts of auxiliary cross-linking agent, 0.05 parts of silane coupling agent monomer, 0.01 part of silane coupling agent oligomer, 0.05 part of ultraviolet absorber and 0.1 part of other light stabilizers.

[0062] This embodiment provides an adhesive film, the adhesive film includes the adhesive film composition, and the specific preparation method is the same as that in Example 1.

Embodiment 3

[0064] The present embodiment provides a film composition containing polystyrene microspheres, the film composition includes 98 parts of ethylene-vinyl acetate copolymer, 5 parts of polystyrene microspheres, 2 parts of main Linking agent, 1 part of auxiliary crosslinking agent, 0.6 part of silane coupling agent monomer, 0.3 part of silane coupling agent oligomer, 0.4 part of ultraviolet absorber and 5 parts of other light stabilizers.

[0065] This embodiment provides an adhesive film, the adhesive film includes the adhesive film composition, and the specific preparation method is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com