Degradable antibacterial fabric and preparation method thereof

A fabric and raw material technology, applied in the field of degradable antibacterial fabric and its preparation, can solve the problems of poor comfort, odor, and hardening of daily necessities, and achieve the effect of improving antibacterial and antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The components of each part by weight of the fabric in Examples 1-5 of the present application are shown in Table 1.

[0040] The composition of each part by weight of fabric in the embodiment 1-5 of table 1

[0041] Example 1 Example 2 Example 3 Example 4 Example 5 Biodegradable polyester 65 75 72 73 68 Plant peptide textile fiber 10 15 14 13 11 Antibacterial cotton 25 30 26 27 27

[0042] In Examples 1-5, the preparation method of degraded polyester includes the following steps: drying the polyester pellets and adding them to a twin-screw extruder, adding BioSphere Plastic 201, melting and blending at 280-300°C, and spinning A thin stream of melt is ejected from the box, and then quickly condensed by the cold air box to form solidified fibers to obtain degradable polyester; the mass ratio of the polyester particles to BioSpherePlastic 201 is 100:0.23.

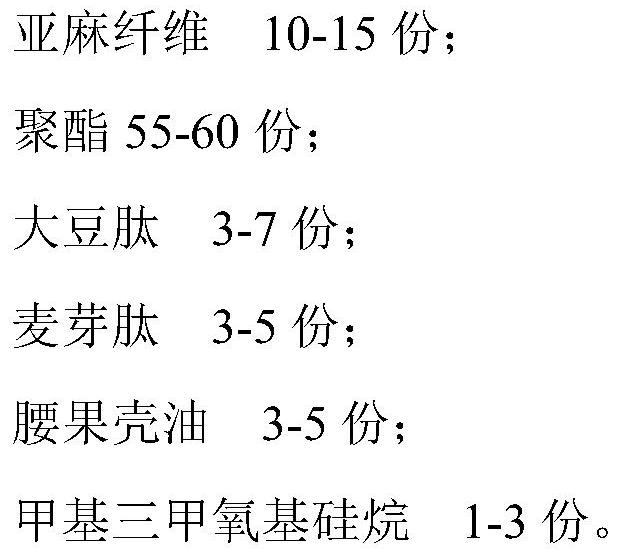

[0043] In Examples 1-5, in parts by weight, the plant peptide ...

Embodiment 6-10

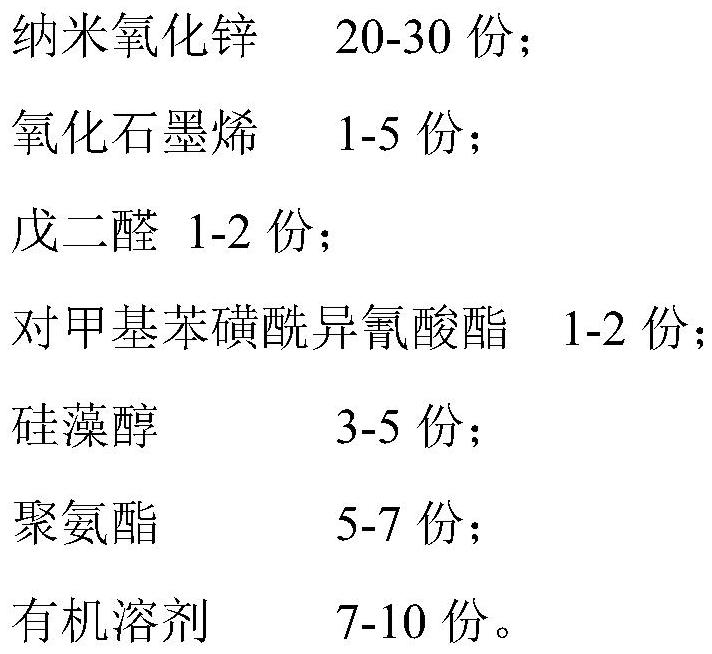

[0051] The difference between Examples 6-10 of the present application and Example 3 is that, in Examples 6-10, the raw materials of each weight part of the fabric finishing agent used are shown in Table 3.

[0052] The weight part of textile finishing agent raw material in the embodiment 6-10 of table 3

[0053]

Embodiment 11-13

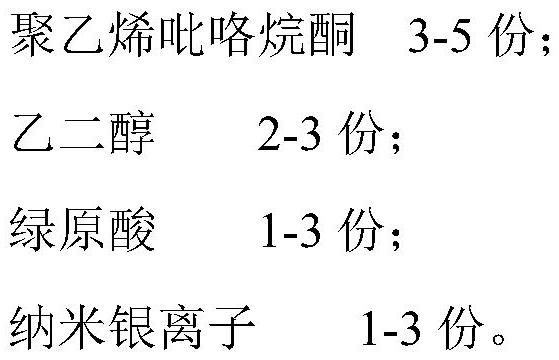

[0055] The difference between Examples 11-13 of the present application and Example 3 is that, in Examples 11-13, the raw materials of each weight part of the fabric finishing agent used are shown in Table 4.

[0056] Parts by weight of fabric finishing agent raw materials in table 4 embodiment 11-13

[0057]

[0058]

[0059] In Examples 1-13 of the present application, the method of using the fabric finishing agent comprises the following steps: immerse the fabric in a mixed solution of finishing agent A and finishing agent B with a volume ratio of 10:1, repeat padding three times, take out the fabric, and One surface of the fabric is sprayed with finishing agent B and dried. After repeated spraying and drying three times, and spraying 0.05mm each time, the fabric is placed in a mixed solution of finishing agent A and finishing agent B with a volume ratio of 2:5, and padding two times. After several times, remove fabric to soap and dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com