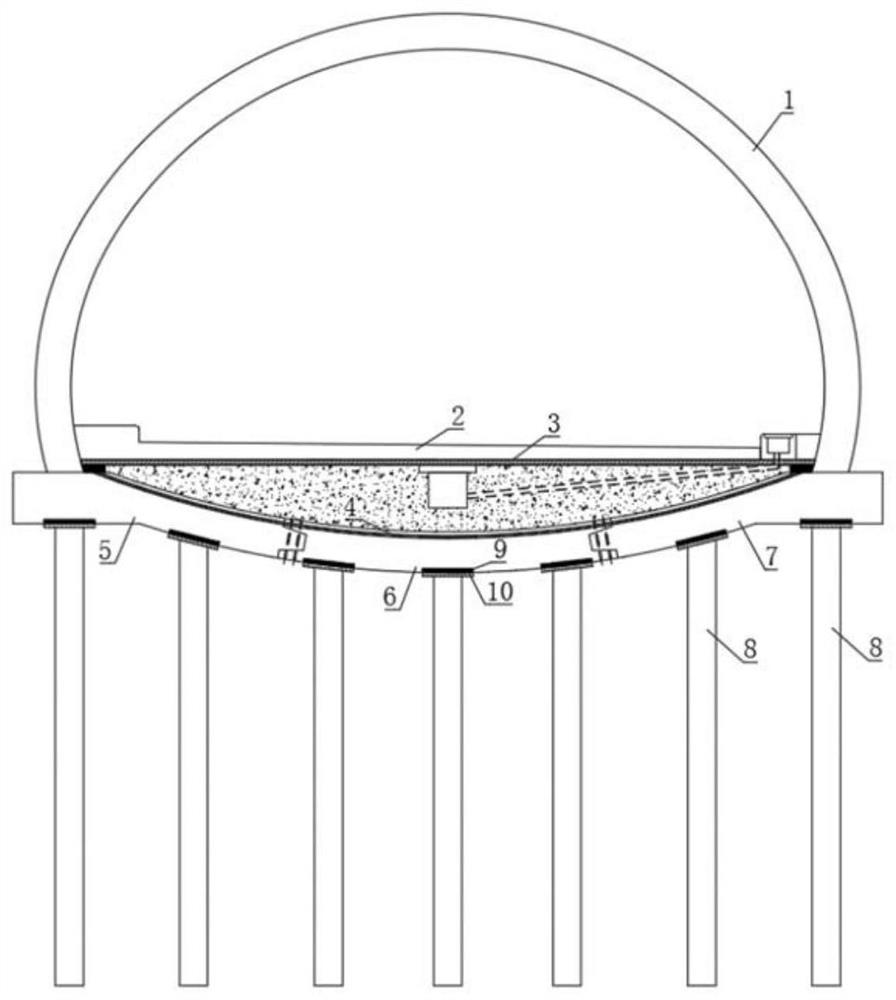

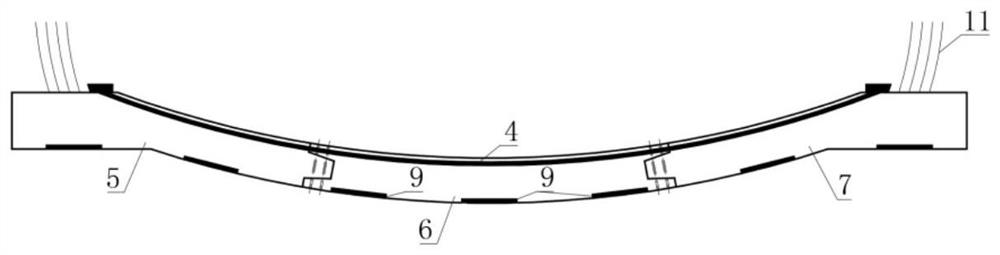

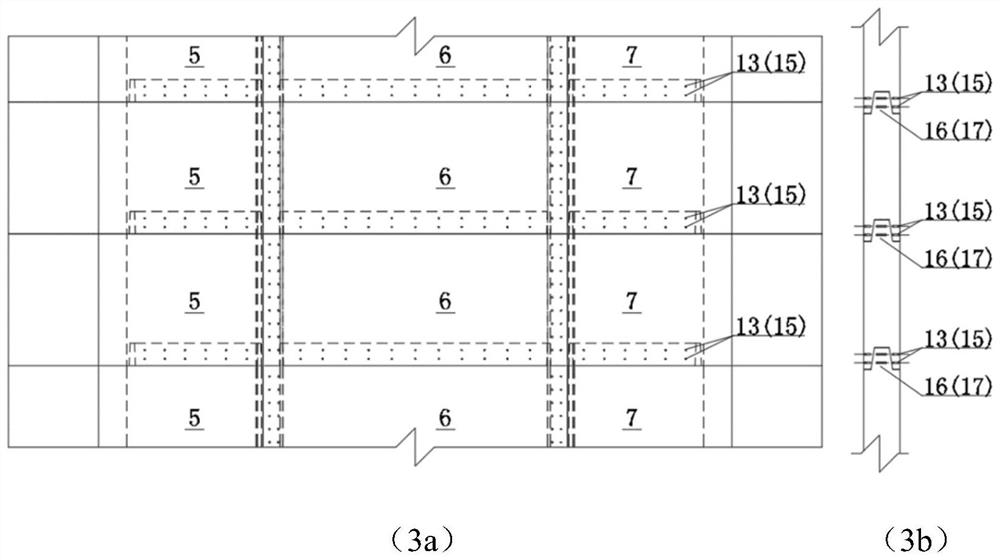

Inverted arch prefabricated assembly structure suitable for loess highway tunnel and construction method

A road tunnel, prefabricated assembly technology, applied in the direction of infrastructure engineering, tunnel, tunnel lining, etc., can solve the problems of poor reinforcement effect and inconvenient construction of prestressed tendons on site, so as to reduce uneven settlement and reduce arch The effect of foot sinking and fast and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

[0041] Glossary

[0042] (1) Loess: A kind of light yellow or brownish-yellow soil, the particle composition is mainly silt particle size (content> 50%), the material particle size is uniform, with pores, no bedding, loose, and vertical joints developed. Quaternary continental sediments rich in calcium carbonate, sometimes containing sulfate or chloride salts, with pores visible to the naked eye.

[0043] (2) Inverted arch: an inverted arched structure set at the bottom of the tunnel to improve the stress conditions of the upper support structure, which is one of the main components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com