Supercritical carbon dioxide gas cooling and recycling device for Brayton cycle power generation system

A technology of Brayton cycle and power generation system, which is applied to steam engine devices, engine components, machines/engines, etc. It can solve the problems of heat affecting the work of rolling bearings, achieve good sealing performance, large cooling area, and ensure normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

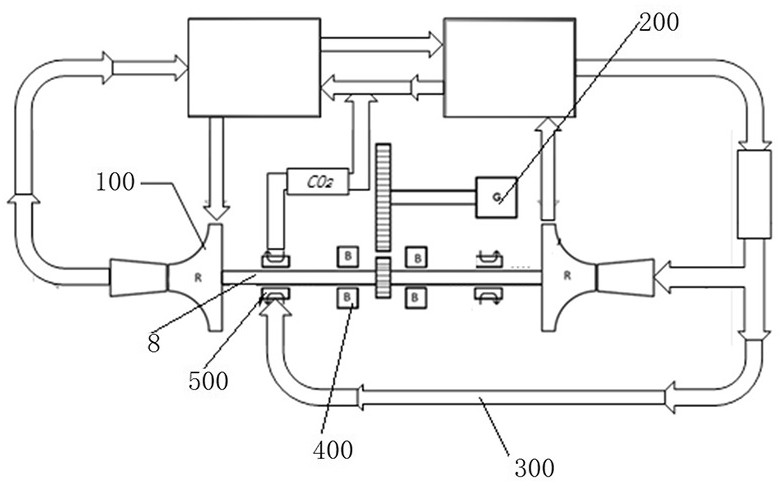

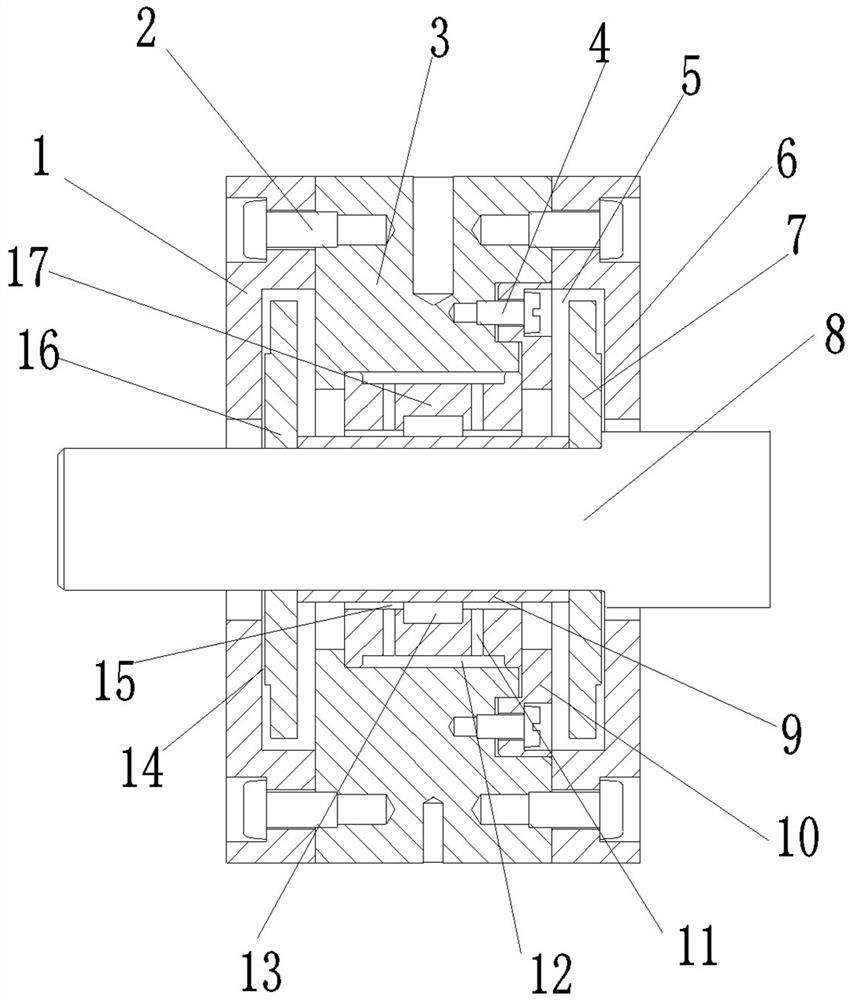

[0043] Such as figure 1 As shown, the supercritical carbon dioxide gas cooling recovery device is applied to the Bretton circulation power generation system in this embodiment, and the Bretton circular power generation system includes a steam turbine 100 and a generator 200, and the steam turbine 100 has an impeller, an impeller fixed mounting. On the impeller power output shaft 8, the impeller power output shaft 8 is supported by the rolling support bearing 400, and the impeller power output shaft 8 is provided with a transmission mechanism between the generator 200, and the corresponding steam turbine 100 is provided with a working fluid circulating gas path 300. In order to provide supercritical carbon dioxide to the steam turbine 100 as a circulating work, the driving turbine 100 is rotated, and when the impeller of the steam turbine 100 is rotated, the generator 200 is driven by the impeller power output shaft 8 to perform power generation.

[0044] Since the temperature of t...

specific Embodiment 2

[0065] Its difference from the first embodiment is mainly in that in the first embodiment, the sealing disk is located within the end rotation chamber of the cooling ring sleeve structure, and the outer side of the opposite side of the two-sealing plate is a sealing side, and there is a spiral groove, and used A dry gas seal is formed. In the present embodiment, the sealing disk may be disposed outside the end of the cooling ring sleeve for forming an assembled gap with both end faces of the cooling ring sleeve, and the inner side surface of each sealing disk is a sealing side. A spiral groove is provided, and a dry gas seal is formed when the two-sealing disk follows the rotation axis.

[0066] At this time, the cooling ring sleeve structure can be provided with a multi-row-in-air hole at one end of the axial direction, and the carbon dioxide gas is input to the cooling chamber. When the other end is provided, the multi-routing recovery hole is provided, and the carbon dioxide ga...

specific Embodiment 3

[0068] Its difference from Example 1 is mainly in: in Example 1, the cooling ring sleeve structure includes an intermediate ring sleeve portion and an internal cloth gaseous shaft, and an internal cloth gas shaft is fixed to the intermediate ring sleeve portion by a fixed end cap. In the present embodiment, the cooling ring sleeve can also be used only a single ring sleeve, at which time, the radial intake hole can be processed on the ring sleeve, and the radial intake hole can be provided, and to achieve a throttling effect. The radial throttle can be designed as a stepped hole structure, and the small diameter segment functions as a throttle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com