Flexible piezoelectric sensing/driving dual-purpose device with intermediate electrode and preparation method of flexible piezoelectric sensing/driving dual-purpose device

An intermediate electrode, piezoelectric sensing technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, materials for piezoelectric devices or electrostrictive devices Selecting other directions can solve the problems of ineffective process control, difficult batch automatic production, difficult actual preparation, etc., and achieve the effect of large flexibility, good piezoelectricity, and improved driving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings and actual cases.

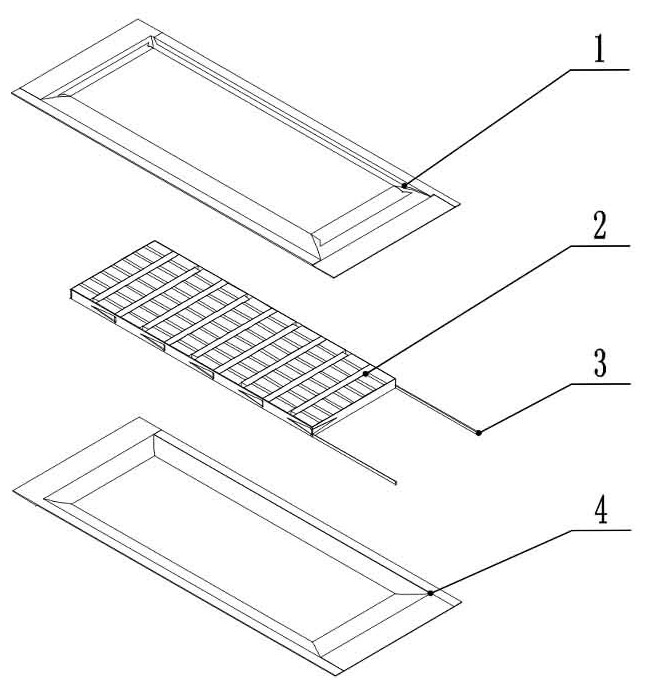

[0046] Such as figure 1 As shown, the flexible piezoelectric sensing / driving dual-purpose device with an intermediate electrode provided by the present invention mainly includes: an upper packaging layer 1 , a flexible piezoelectric functional material 2 , a lateral lead-out electrode 3 , and a lower packaging layer 4 .

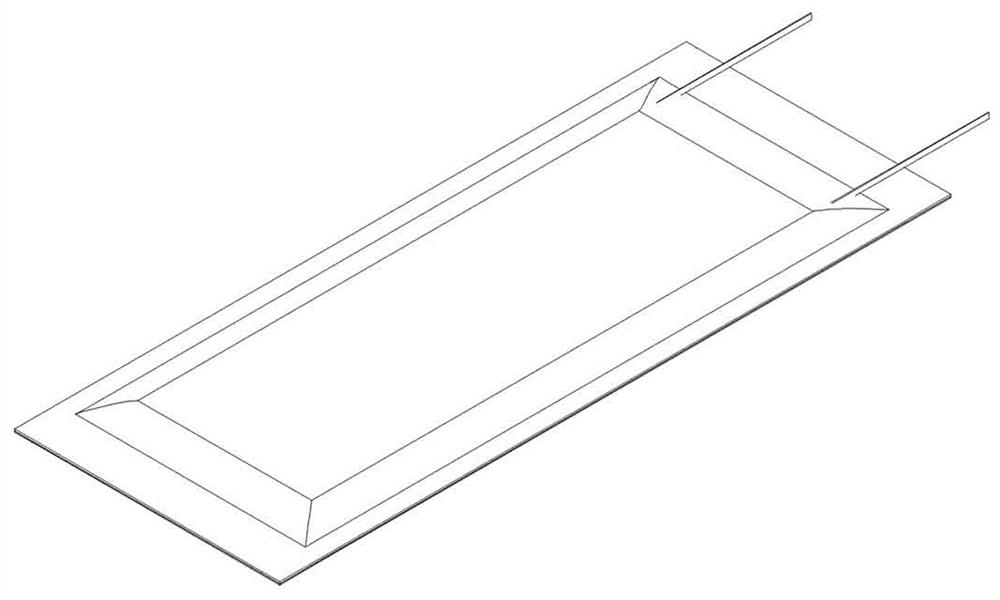

[0047] Such as figure 2 As shown, the device structure of the flexible piezoelectric sensing / driving dual-purpose device with an intermediate electrode provided by the present invention.

[0048] Such as image 3 As shown, the device structure of the flexible piezoelectric sensing / driving dual-purpose device with an intermediate electrode provided by the present invention.

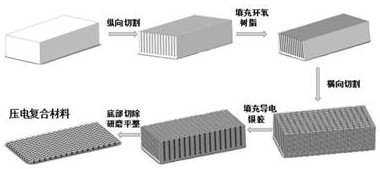

[0049] Such as Figure 4 Shown is a schematic diagram of the structure of the flexible piezoelectric functional material.

[0050] Such as Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com