Positive electrode lithium supplementing material and preparation method and application thereof

A positive electrode material and lithium supplement technology, applied in the field of energy storage, can solve the problem that the effect of lithium supplement is difficult to further improve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In the second aspect, the present application provides a method for preparing a positive electrode lithium supplement material, which includes: mixing the lithium source, the silicon source, and the boron source, and then sintering; wherein, the B in the boron source and the Si in the silicon source The molar ratio is x:(1-x), 0<x≤0.2; the molar ratio of Li in the lithium source to Si in the silicon source is (1.6-4.4):1.

[0037] Wherein, when the molar ratio of Li in the lithium source and Si in the silicon source is (1.6-2.2): 1, the core material prepared at this moment is a boron-doped lithium metasilicate material, when Li in the lithium source and the silicon source The Si molar ratio in Li is (3.2-4.4): 1, and the core material prepared at this time is a boron-doped lithium orthosilicate material, and when 2.2<Li and the Si molar ratio in the silicon source are <3.2, prepare The core material is a composite of boron-doped lithium orthosilicate material and boron...

Embodiment 1

[0053] Boron-doped lithium orthosilicate materials and boron-doped carbon-coated lithium orthosilicate materials (a1, a2, a3) were prepared.

[0054] Boron-doped lithium orthosilicate material (a1): the precursor obtained by mixing and ball-milling the corresponding raw materials in Table 1, and sintering the precursor in a tube furnace for the corresponding time in Table 1.

[0055] Carbon-coated boron-doped lithium orthosilicate (a2): the precursor obtained by mixing and ball-milling the corresponding raw materials in Table 1, and sintering the precursor in a tube furnace under the protection of argon.

[0056] Carbon-coated boron-doped lithium orthosilicate (a3): the precursor is obtained by mixing and ball-milling the corresponding raw materials in Table 1, putting the precursor into a tube furnace for sintering, and passing acetylene during the sintering process.

[0057] Table 1 Raw materials and reaction conditions of samples a1-a3

[0058]

[0059]

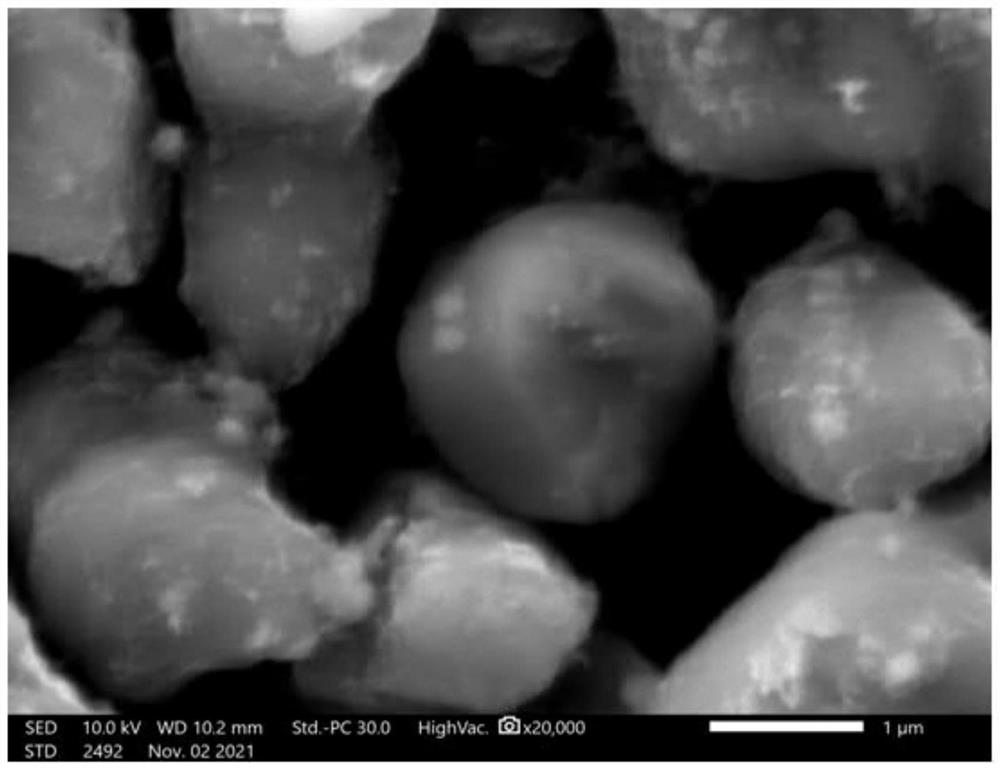

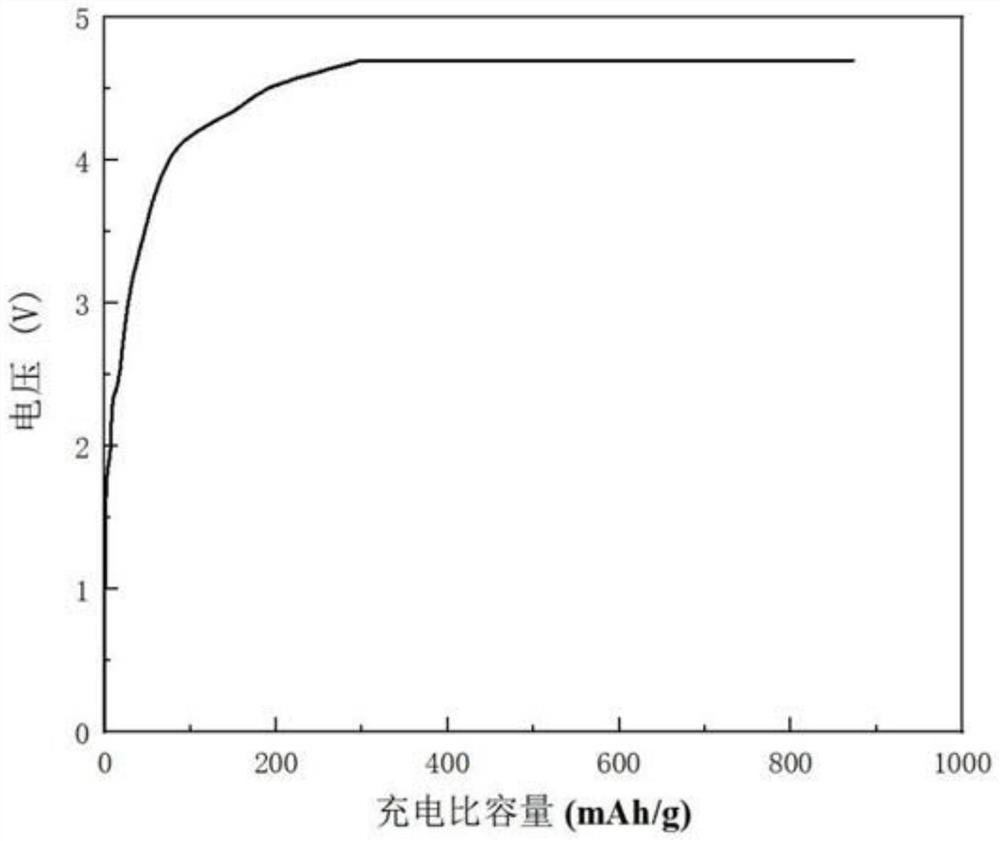

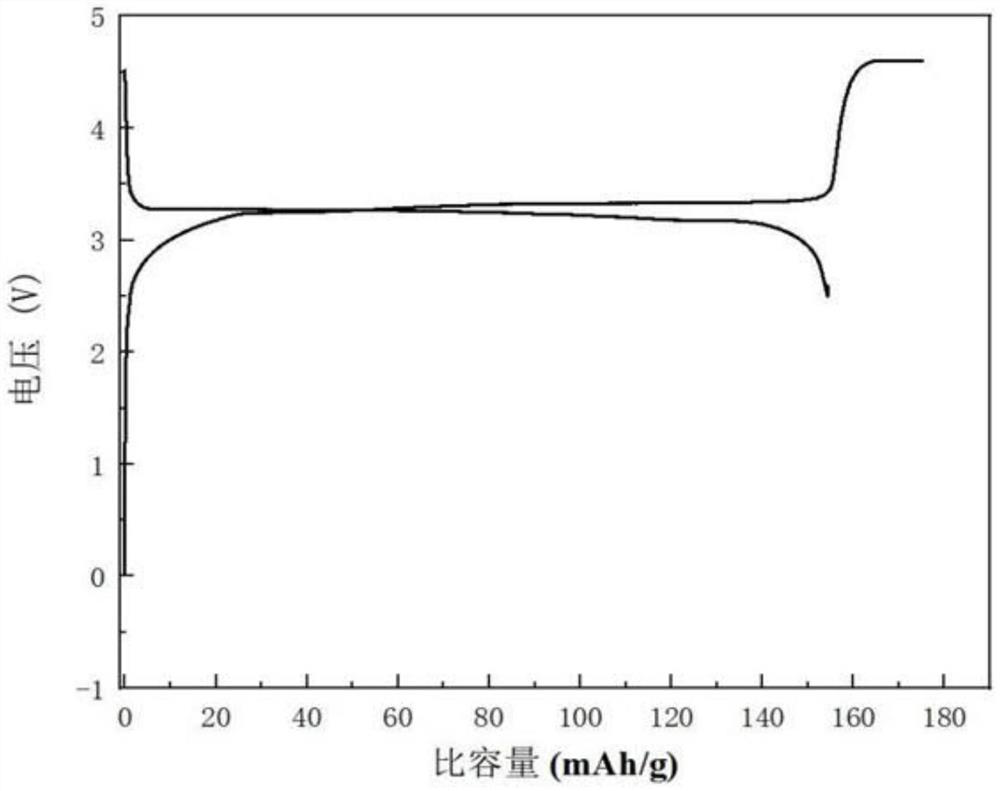

[0060] fig...

Embodiment 2

[0066] Boron-doped lithium orthosilicate materials and boron-doped carbon-coated lithium orthosilicate materials (b1, b2, b3) were prepared.

[0067] Among them, the boron-doped lithium orthosilicate material (b1): obtained by mixing the corresponding raw materials in Table 3 and ball milling to obtain a precursor, putting the precursor in a tube furnace and sintering the corresponding time in Table 3 under the protection of argon.

[0068] Carbon-coated boron-doped lithium orthosilicate (b2): the precursor obtained by mixing and ball-milling the corresponding raw materials in Table 3, and sintering the precursor in a tube furnace under the protection of argon.

[0069] Carbon-coated boron-doped lithium orthosilicate (b3): the precursor is obtained by mixing and ball-milling the corresponding raw materials in Table 3, putting the precursor into a tube furnace for sintering, and feeding ethylene during the sintering process.

[0070] Table 3 Raw materials and reaction conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com