Method for forming metal nitride thin film

A technology of nitrides and metals, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of device electrical characteristics degradation, reduction of storage capacity, difficulty in forming, etc., and achieve high thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

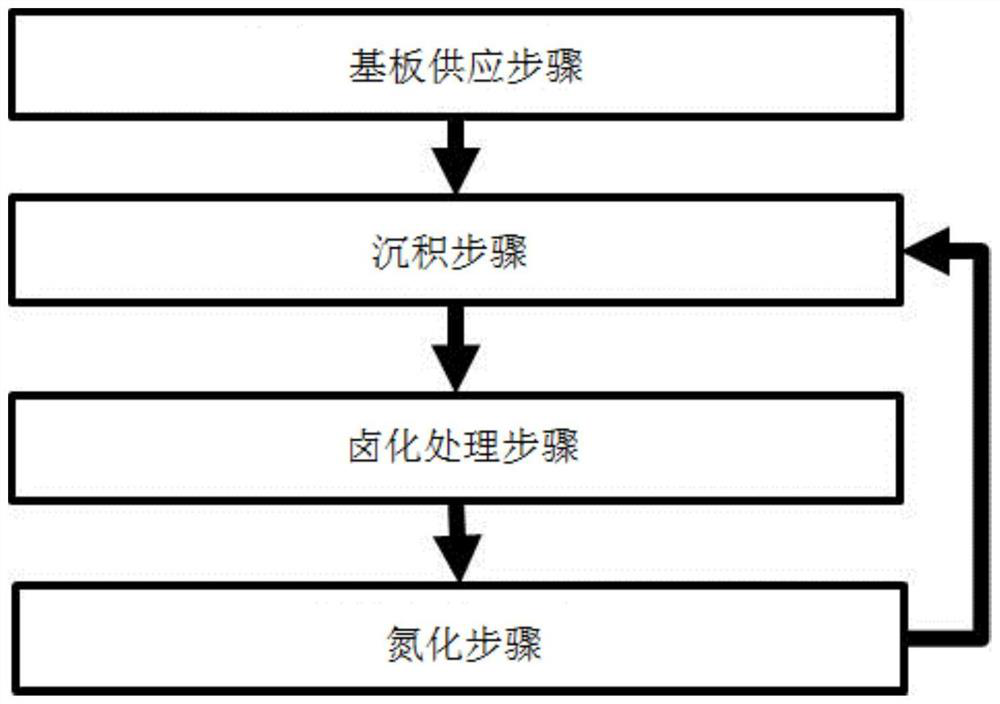

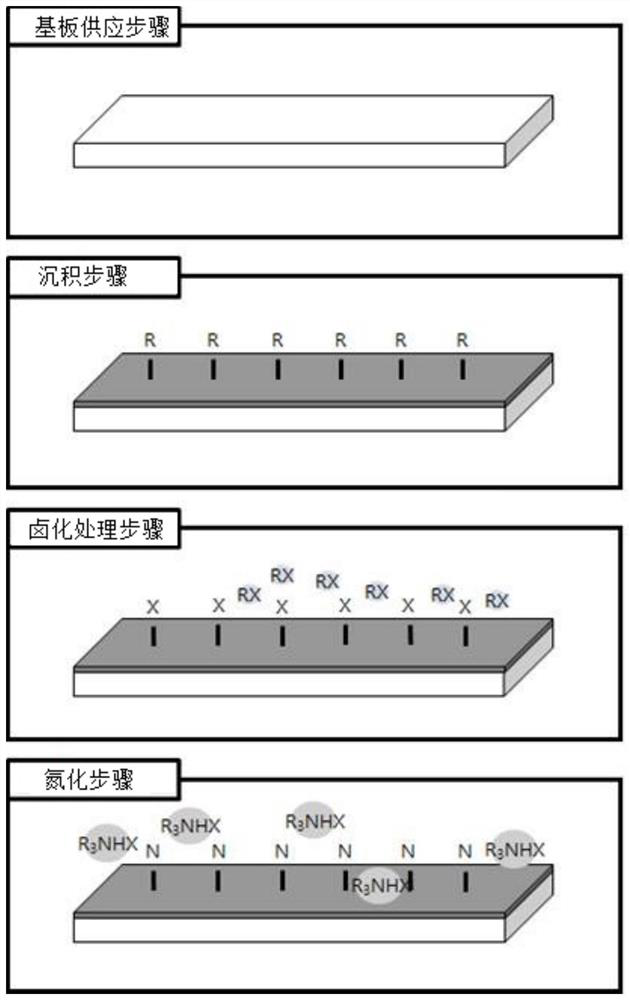

[0036] Below, refer to Figures 1 to 3 Preferred embodiments of the present invention are described in more detail. The embodiments of the present invention can be modified into various forms, and the scope of the present invention should not be construed as being limited to the embodiments described below. The following examples are provided to explain the present invention in more detail to those skilled in the art to which the present invention pertains. Therefore, the shape of each component shown in the drawings may be exaggerated in order to emphasize clearer illustration.

[0037] First of all, the used precursor NbCl5 is a solid, so the pipes in the deposition equipment will be clogged, and it is difficult to transfer a certain amount to the deposition chamber after sublimation into a gas. In addition, other organometallic precursors have a large carbon content, so there is a problem that impurities affect film quality.

[0038] The formation method of the metal (Ⅴ)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com