Method for biomimetic mineralization and cementation of loose sand grains

A biomimetic mineralization and cementation technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of difficult to control microbial distribution in situ activity, harsh microbial growth environment, pollution of by-products, etc., to save cementation costs , high strength, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

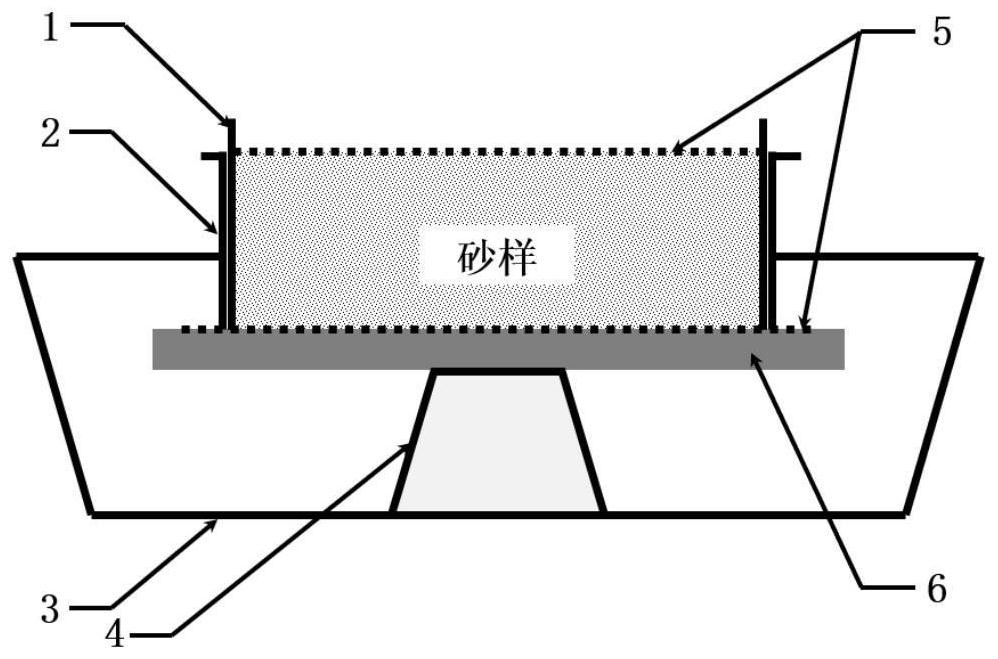

[0059] In order to further understand the content, features and effects of the present invention, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0060] This embodiment provides a method for biomimetic mineralization and cementation of loose sand, which is carried out according to the following steps:

[0061] 1. Preparation of cementing liquid

[0062] Cementing solution A: Weigh a certain amount of L-aspartic acid (L-Asp) and calcium chloride solid, dissolve in water and stir evenly, and prepare CaCl 2 — L-Asp mixed solution; and use 1mol / L NaOH solution to adjust the pH value to 8-11. CaCl 2 —L-Asp: Ca in L-Asp mixed solution 2+ The molar mass ratio is 0.5:1~2:1, Ca 2+ The concentration is 1mol / L.

[0063] Cementing solution B: Weigh a certain amount of sodium carbonate solid, dissolve it in water and stir evenly, and prepare Na 2 CO 3 solution, the pH is the natural pH. Na 2 CO 3 CO in solution 3 2- 1mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com