Method for promoting efficient enrichment of precious metals in anode mud by tartaric acid

A technology of anode slime and tartaric acid, applied in the field of comprehensive recovery of solid waste resources, can solve problems such as difficult to remove efficiently and inactive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Alkali roasting, water immersion

[0033] (1) Dry the anode slime and grind it into a powder with a particle size of less than 200 mesh, mix it with NaOH and roast, control the mass ratio of NaOH to mud at 1:1, roast at 700°C, and roast for 2.0 hours to obtain roasted mud .

[0034] (2) Perform stirring and leaching reaction on the mud obtained by roasting in step (1) with water, control the liquid-solid ratio to 25 / 1, the temperature at 90° C., and the rotational speed at 300 rpm, and react for 1.5 hours. After the reaction, the solid-liquid separation was carried out to obtain the water soaked residue, which was washed and dried at 75°C for 12 hours for storage.

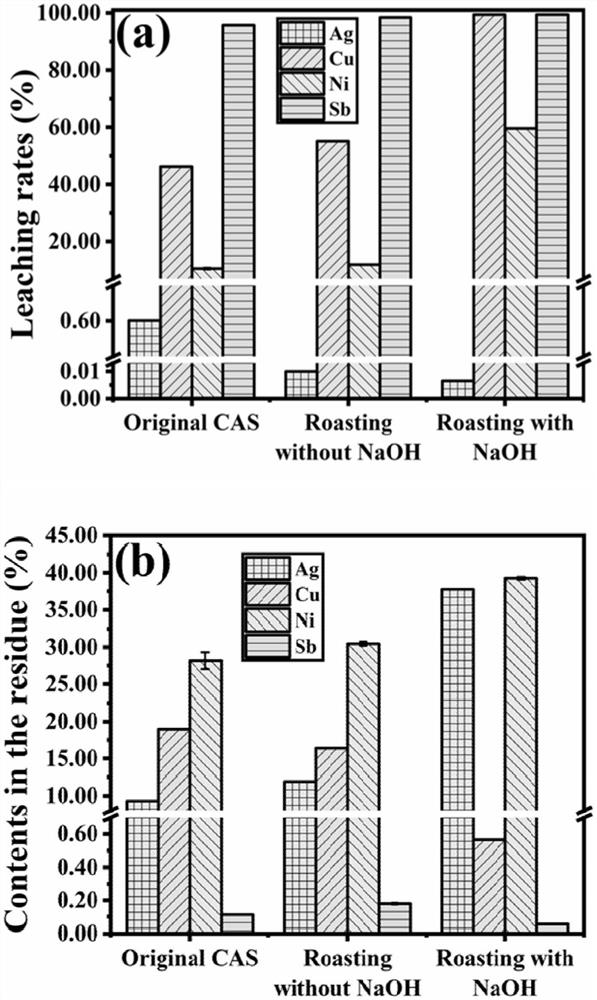

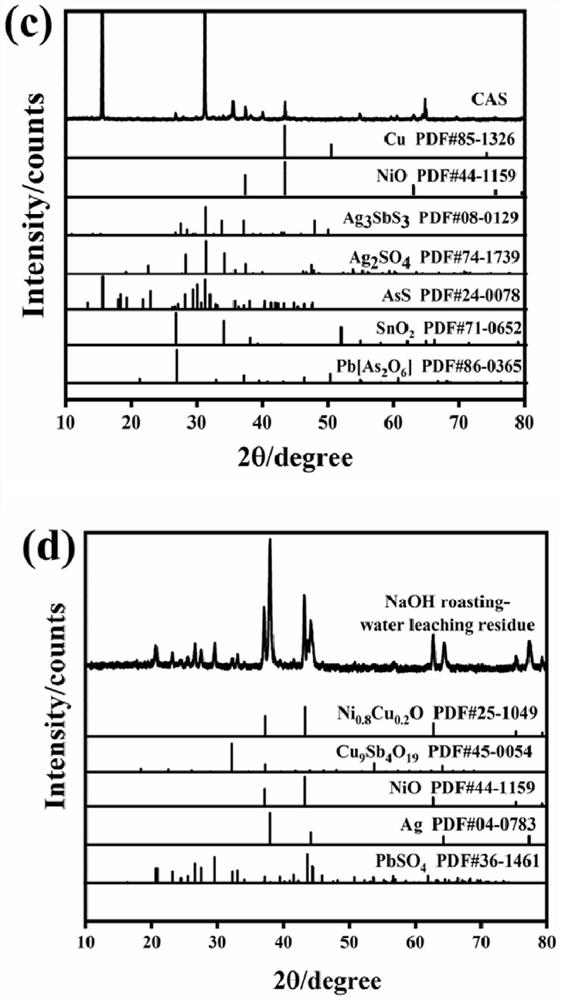

[0035] Roasting realizes the transformation of the phase of the anode slime towards the direction where impurities are easier to remove and precious metals are easier to retain. Compared with the control with anode slime as the leaching object, the leaching rate of impurities Cu, Ni and Sb in the sample ro...

Embodiment 2

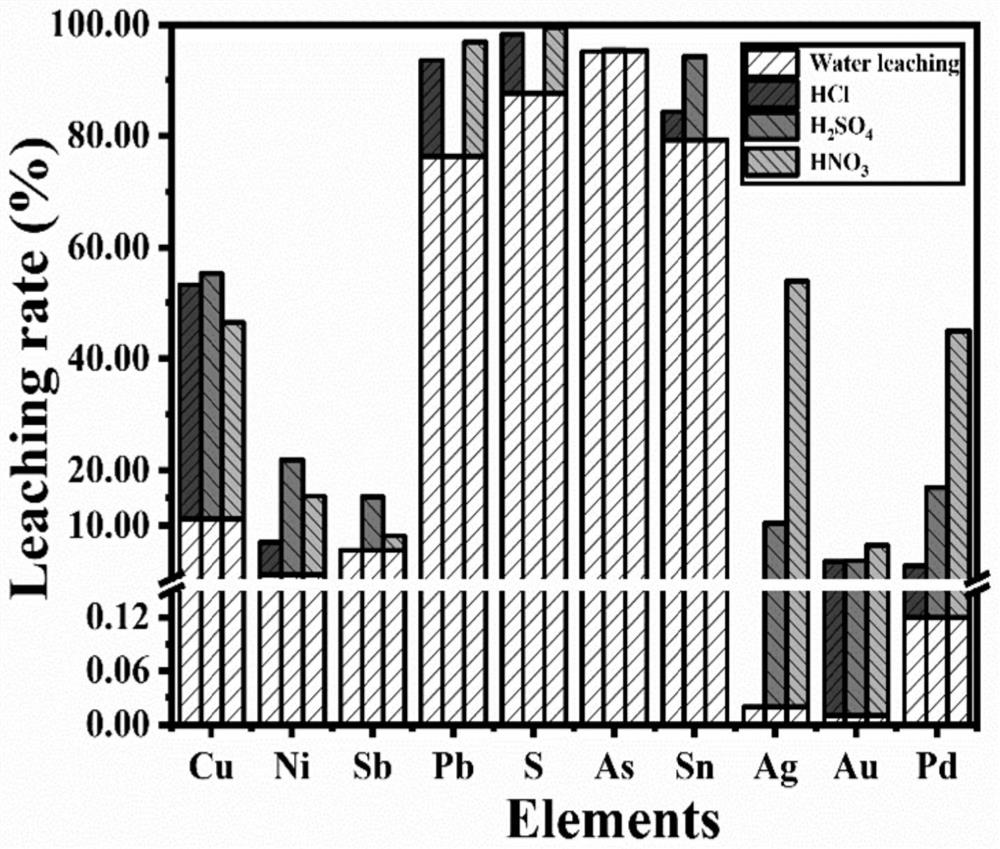

[0038] Tartaric Auxiliary H 2 SO 4 -H 2 o 2 Efficiently leaching impurities Cu and Sb, and retaining precious metals Ag, Au and Pd.

[0039] Add 10.00 g of tartaric acid into an Erlenmeyer flask filled with 200 mL of 2.0 mol / L sulfuric acid, place in an oil bath and stir at a speed of 300 rpm to raise the temperature to 70°C. After the temperature stabilized, add 5.00g of dried mud after alkali roasting-water immersion, and then slowly inject it along the bottle wall (H 2 o 2 Directly add 10mL of 30% H 2 o 2 ,start the timer. Added 2.0g NaCl without adding tartaric acid as the control group. After the reaction was carried out for 40 minutes, solid-liquid separation was carried out to obtain precious metal-enriched slag, which was centrifuged, washed, and dried at 75° C. for 12 hours. Take out about 1mL leachate filter membrane with a syringe, dilute with 2% (v / v) nitric acid and measure the content of impurities (Cu, Ni and Sb) and precious metals (Ag, Au and Pd) by A...

Embodiment 3

[0042] The concentration of tartaric acid in the leaching system is optimized to efficiently remove impurities and enrich precious metals at the same time.

[0043] A certain amount of tartaric acid was added into an Erlenmeyer flask filled with 200 mL of 2.0 mol / L sulfuric acid, placed in an oil bath and stirred at a speed of 300 rpm to raise the temperature to 70°C. After the temperature is stable, add 5.00g of dried mud after alkali roasting-water immersion, and then slowly inject 10mL of 30% H2O along the bottle wall. 2 o 2 ,start the timer. The control tartaric acid concentration is 0.17, 0.27, 0.33, 0.40, 0.50mol / L (due to the added H 2 o 2 Less, when calculating the concentration of tartaric acid, ignore H 2 o 2 volume). After the reaction was carried out for 40 min, about 1 mL of the leaching solution was taken out with a syringe to filter the membrane, and after being diluted with 2% (v / v) nitric acid, the impurities (Cu, Ni, and Sb) and precious metals (Ag, Au,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com