Manufacturing process carbon efficiency evaluation method

A technology of manufacturing process and efficiency, applied in the field of carbon efficiency evaluation of manufacturing process, can solve the problems of difficult to truly reflect the pros and cons of processing technology, weak guiding role of manufacturing process, lack of product comparison, etc. The effect of sex, convenient development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

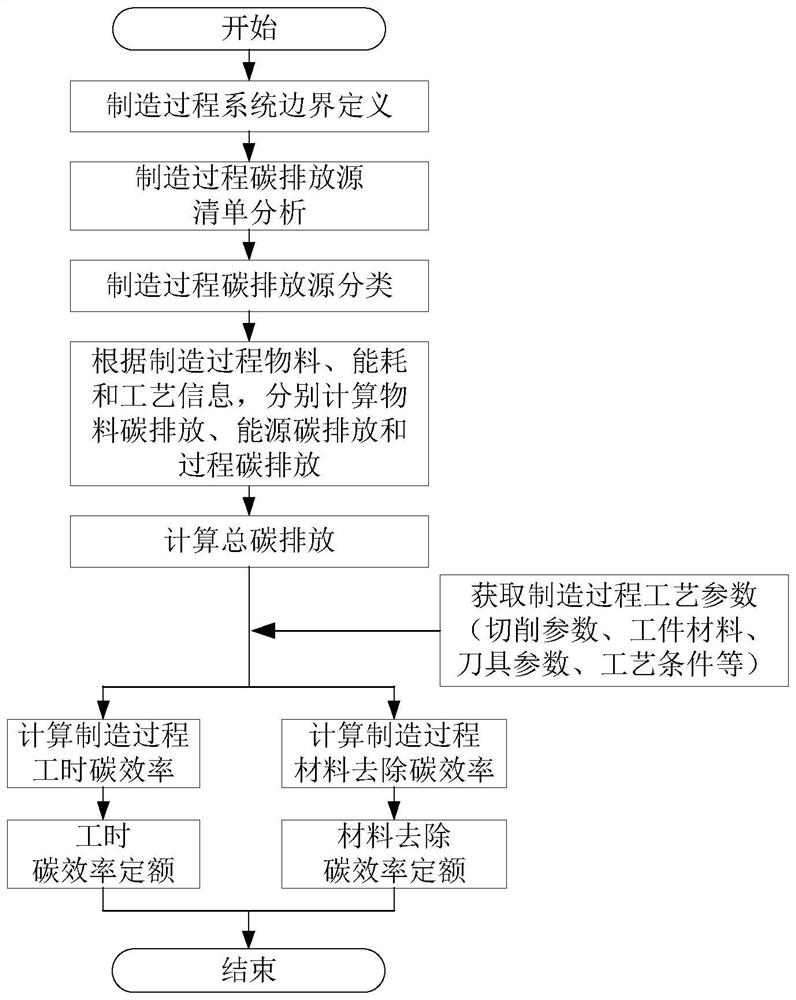

[0060] see figure 1 , this embodiment discloses a manufacturing process carbon efficiency assessment method, including the following steps:

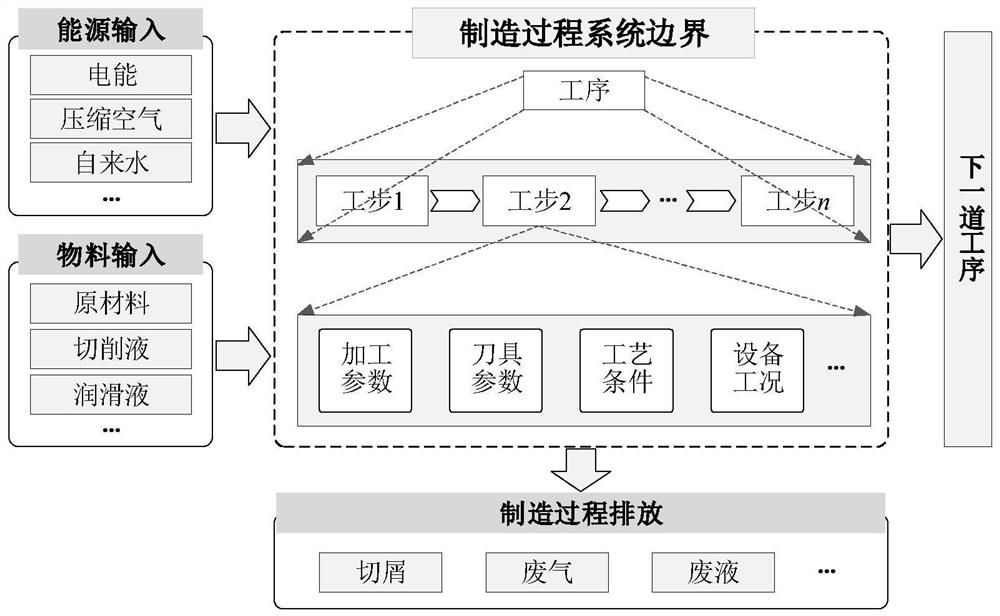

[0061] 1) According to the characteristics of the manufacturing system, define the boundary of the manufacturing process system and conduct inventory analysis of carbon emission sources; see figure 2 , is defined as the carbon emission boundary of the manufacturing process;

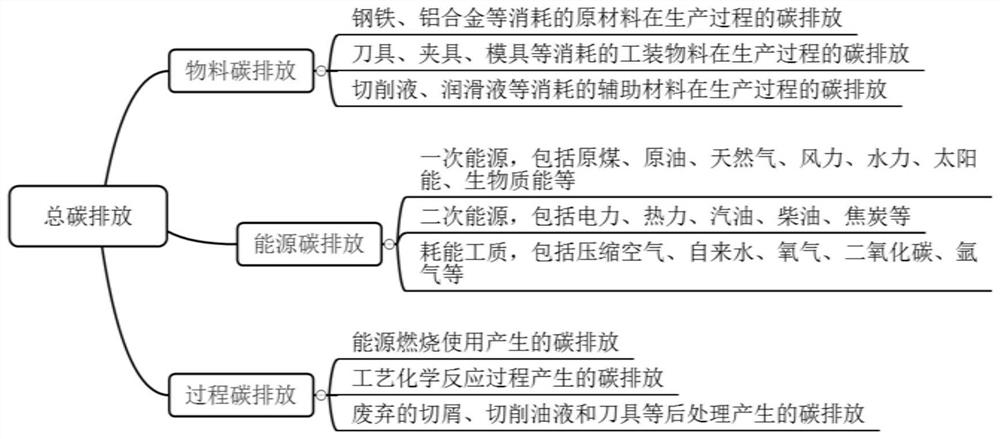

[0062] 2) see image 3 , according to the characteristics of the carbon emission source, classify the carbon emission source in the manufacturing process, and define the corresponding carbon source generalized characteristic function according to the manufacturing process material, energy consumption and process information, and establish the material carbon emission and energy carbon emission in the manufacturing process , process carbon emissions, and total carbon emissions models; see Figure 4 , is the way to obtain carbon emission data in the manufacturing ...

Embodiment 2

[0134] see figure 1 , this embodiment discloses a manufacturing process carbon efficiency assessment method, including the following steps:

[0135] 1) According to the characteristics of the manufacturing system, define the boundary of the manufacturing process system and conduct inventory analysis of carbon emission sources;

[0136] 2) According to the characteristics of carbon emission sources, classify carbon emission sources in the manufacturing process, and define the corresponding carbon source generalized characteristic function according to the manufacturing process materials, energy consumption and process information, and establish the material carbon emission and energy carbon emission in the manufacturing process. Emissions, process carbon and total carbon models;

[0137] 3) Combining with the process parameters of the manufacturing process, from the two dimensions of processing time and material removal, define the man-hour carbon efficiency and material remov...

Embodiment 3

[0140] The main steps of this embodiment are the same as in Embodiment 2, further, the manufacturing process process parameters described in step 3) include cutting parameters, workpiece materials, tool parameters and process conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com