Laser cleaning control method and control system based on LIBS (laser-induced breakdown spectroscopy) technology online monitoring

A laser cleaning and control system technology, applied in the field of laser cleaning, can solve the problems of inability to clean the quality assessment, inability to judge the cleaning process, etc., to achieve rapid online monitoring and control, increase the scope of application, improve efficiency and effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

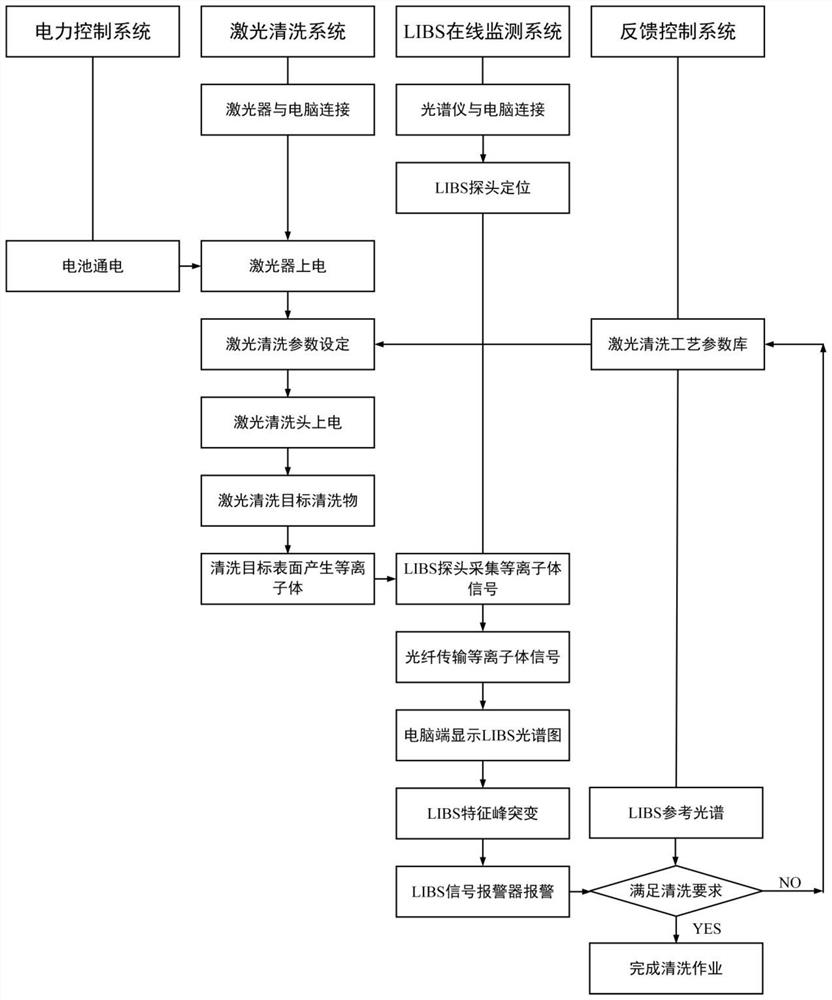

[0061] Embodiment 1: Laser cleaning control method based on online monitoring of LIBS technology

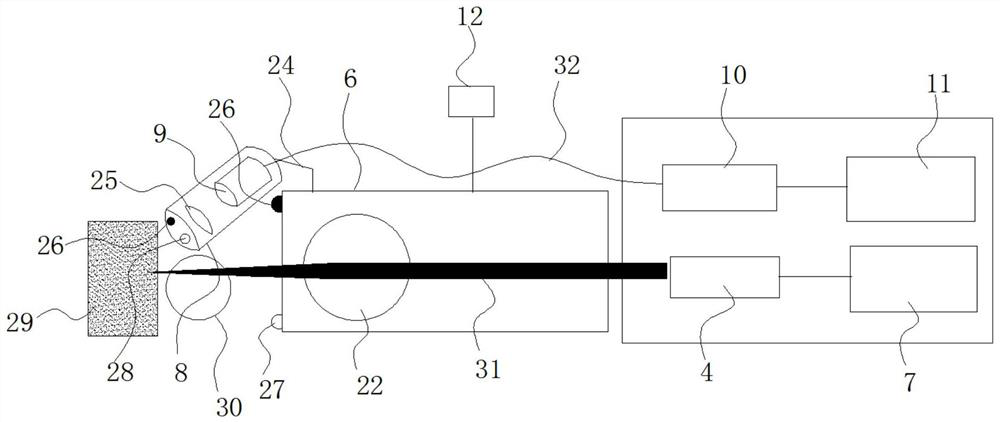

[0062] In the embodiment of the present invention, please refer to Figure 1-3 Shown, a kind of laser cleaning control method based on LIBS technology online monitoring, comprises the following steps:

[0063] S1: Laser cleaning: set the laser cleaning head and laser, the laser emits laser beams, and hold the laser cleaning head to perform laser cleaning on the cleaning target surface;

[0064] S11: Hold the laser cleaning head at the cleaning target, keep a safe distance of 1-2cm between the front end of the laser cleaning head and the cleaning target, and prevent contact or collision between the cleaning head and the cleaning target;

[0065] S12: The computer controls the digital delay pulse generator to provide a trigger signal to the laser, so that the laser is turned on, and the laser emits a laser beam for cleaning the target surface;

[0066] S13: The laser beam emitted...

Embodiment 2

[0079] Embodiment 2: Laser cleaning control system based on online monitoring of LIBS technology

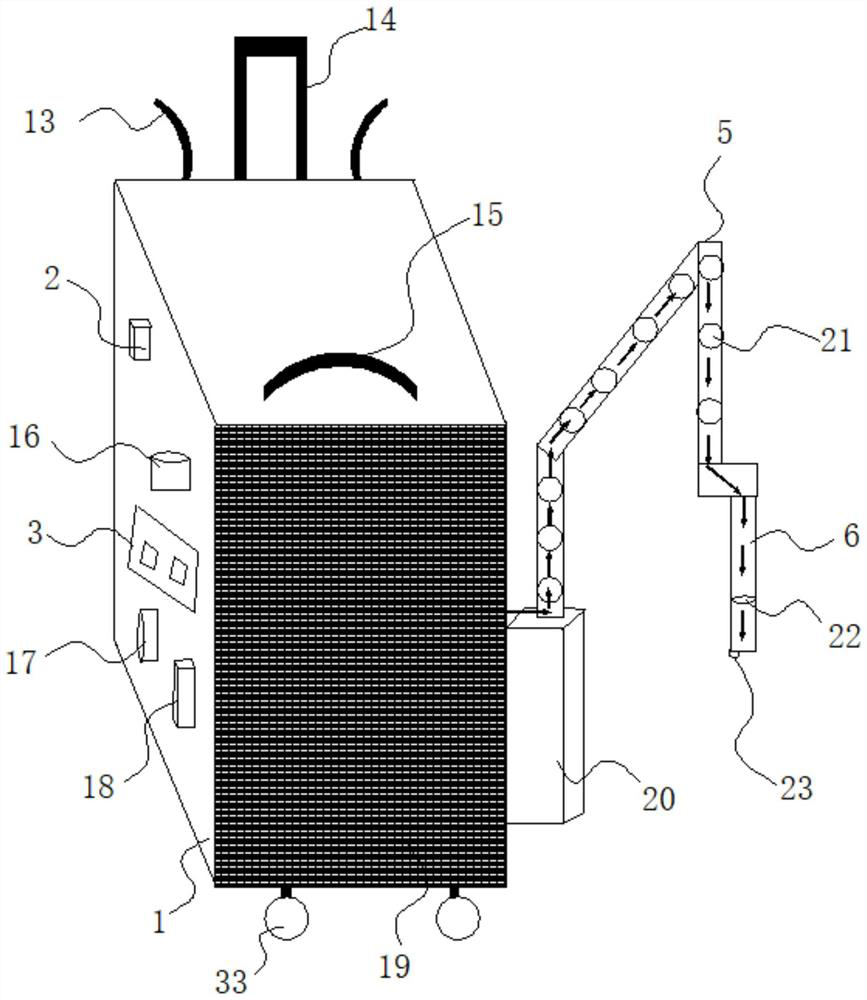

[0080] Please continue to refer Figure 1-3 As shown, a laser cleaning control system based on LIBS technology online monitoring, including the main box, laser cleaning system and LIBS online monitoring system;

[0081] The main chassis includes a power system, a cooling system and a digital delay pulse generator;

[0082] The cooling system includes a heat dissipation fan arranged outside the shell of the main box, which is used for ventilation and heat dissipation inside the main box to avoid damage to components caused by excessive temperature; two USB interfaces are arranged outside the shell of the main box, One of the USB interfaces is used to connect a computer and a cleaning machine, and the other USB interface is used to connect a computer and a spectrometer;

[0083] The laser cleaning system includes a laser, a multi-joint light guide arm for guiding the laser beam, ...

Embodiment 3

[0101] Example 3: Application of online monitoring of aircraft aluminum alloy skin laser layered paint removal based on LIBS technology

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com