Preparation process of biaxially oriented polyethylene heat-sealing film and automatic assembly line

A technology of biaxial stretching and preparation process, which is applied in the field of preparation process and automatic assembly line of biaxially stretched polyethylene heat-sealing film, to achieve the effect of reducing length, ensuring transverse stretching effect and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

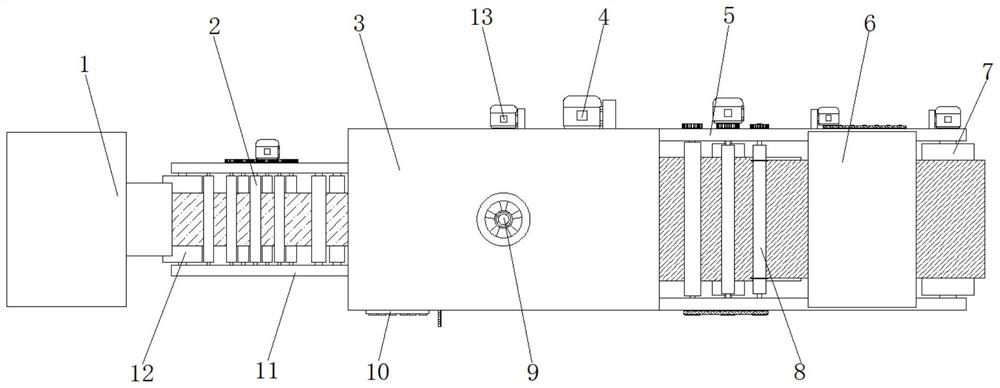

[0048] Example 1, such as Figure 1-3 As shown, after the core material enters the twin-screw extruder, it is necessary to remove excess air during the plasticization of the raw material, and then perform secondary plasticization, metering and filtration, and set its temperature to 230-240 °C; The surface layer raw materials are extruded and filtered through single-screw and twin-screw extruders. The temperature of the upper surface layer is set at 230-240°C, the temperature of the upper and lower surface layers is set at 235-245°C, and the temperature of the lower surface layer is set at 235°C. -245°C to ensure that the materials of the core layers of each layer adhere to each other.

Embodiment 2

[0049] Example 2, such as Figure 1-3 As shown, when the five-layer raw materials are controlled to be co-extruded through the die of the five-layer co-extrusion extruder 1, the temperature of the die is set at 235-245°C, the temperature of the chilling roll is set at 22-26°C, and the temperature of the cooling pool During the longitudinal stretching process, the temperature of the preheating zone is 108-118°C, the temperature of the stretching roller is 70-95°C, the stretch ratio is 4.8-5.2 times, and the temperature of the setting roller is 105- 125°C. During the transverse stretching process, the temperature in the preheating zone is 122-126°C, the temperature in the stretching zone is 115-120°C, the temperature in the shaping zone is 110-120°C, and the temperature in the cooling zone is room temperature. The stretch ratio is 7.5-8.8 times, so as to ensure the stretching effect of each stretching stage of the film raw material.

Embodiment 3

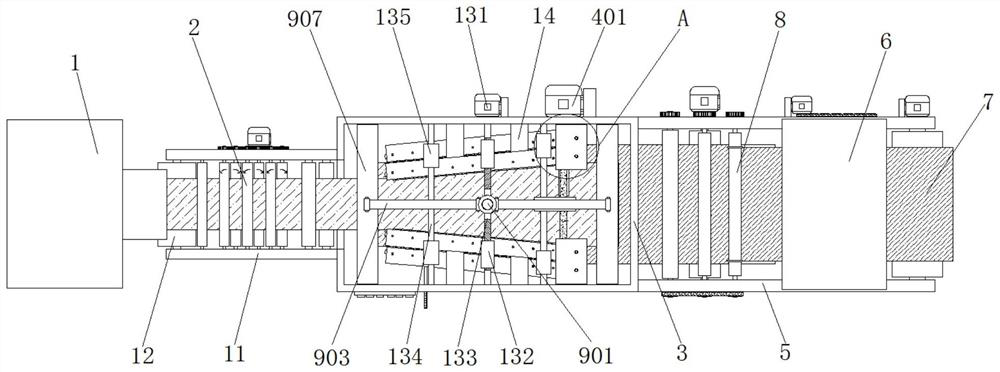

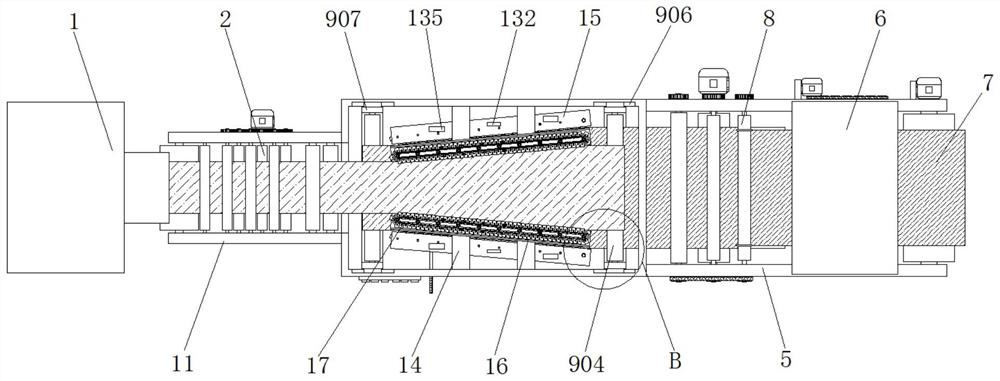

[0050] Example 3, such as Figure 1-5As shown in and 9, the operator controls the servo motor 131 through the control panel 10 to drive the second threaded rod 133 to rotate clockwise, and uses the thread to force the two sets of first mounting brackets 132 to approach each other, thereby driving the second threaded rods at both ends of the transverse stretching chamber 3. The U-shaped frame 15 and the first U-shaped frame 16 are automatically close to each other, and the second mounting frame 135 also slides on the sliding rod 134, thereby realizing adjustment between two groups of second U-shaped frames 15 and two groups of first U-shaped frames 16 The distance between them is correspondingly adjusted to the width of the film after transverse stretching, which improves the functionality of the polyethylene film automatic assembly line, and can be freely selected according to the degree of stretching that the film of different materials can withstand per unit time. Whether a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com