Polycaprolactone microspheres and preparation method thereof

A technology of polycaprolactone and microspheres, which is applied in the field of polycaprolactone microspheres and its preparation, can solve problems such as operator injury, and achieve the effects of simple preparation process, improved preparation efficiency, and reduced preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] In order to solve the problem that in the existing preparation process of polycaprolactone microspheres, it is easy to cause harm to operators due to the introduction of organic solvents, the present invention provides a preparation method of polycaprolactone microspheres, comprising the following steps:

[0023] S1: After the liquid nitrogen pulverizer is fed with liquid nitrogen, polycaprolactone is added to the liquid nitrogen pulverizer for pulverization while freezing to obtain polycaprolactone particles;

[0024] S2: Mix polycaprolactone particles with surfactant aqueous solution at a temperature of 60°C to 80°C, stir, and successively pass through wet ball sieving, water washing, centrifugation, drying, and dry ball sieving to obtain polycaprolactone Microspheres.

[0025] The temperature range of liquid nitrogen freezing in the preferred step S1 of the present application is -120°C to -70°C; and the frozen polycaprolactone is preferably pulverized by a DC3-1 liq...

Embodiment 1

[0037] S1: After feeding liquid nitrogen into the liquid nitrogen pulverizer, add polycaprolactone into the liquid nitrogen pulverizer for pulverization while freezing to obtain polycaprolactone particles, the particle size of which is about 75 μm; Weigh 2g polycaprolactone granules and set aside;

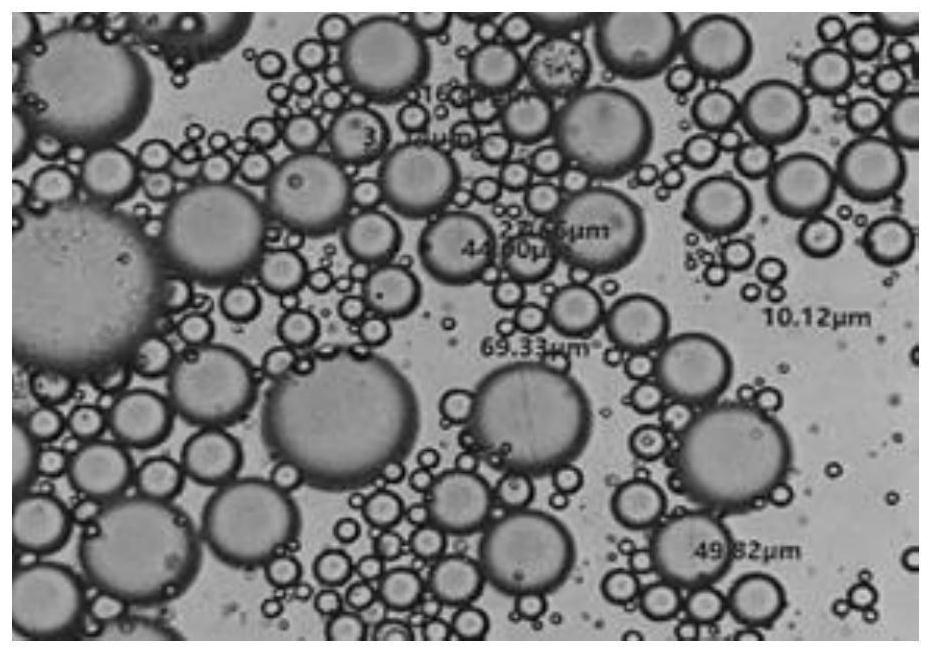

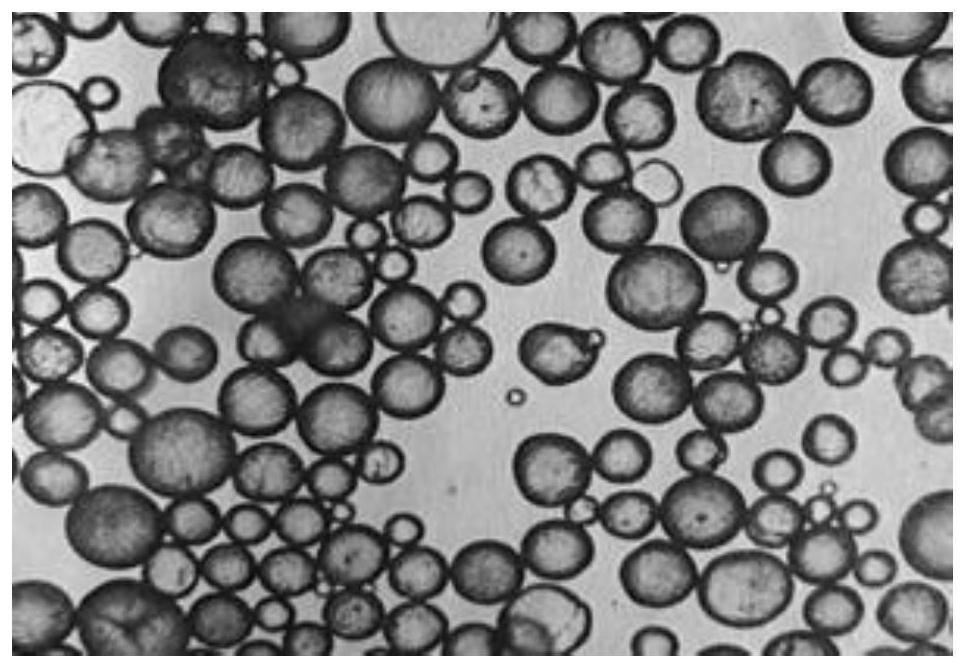

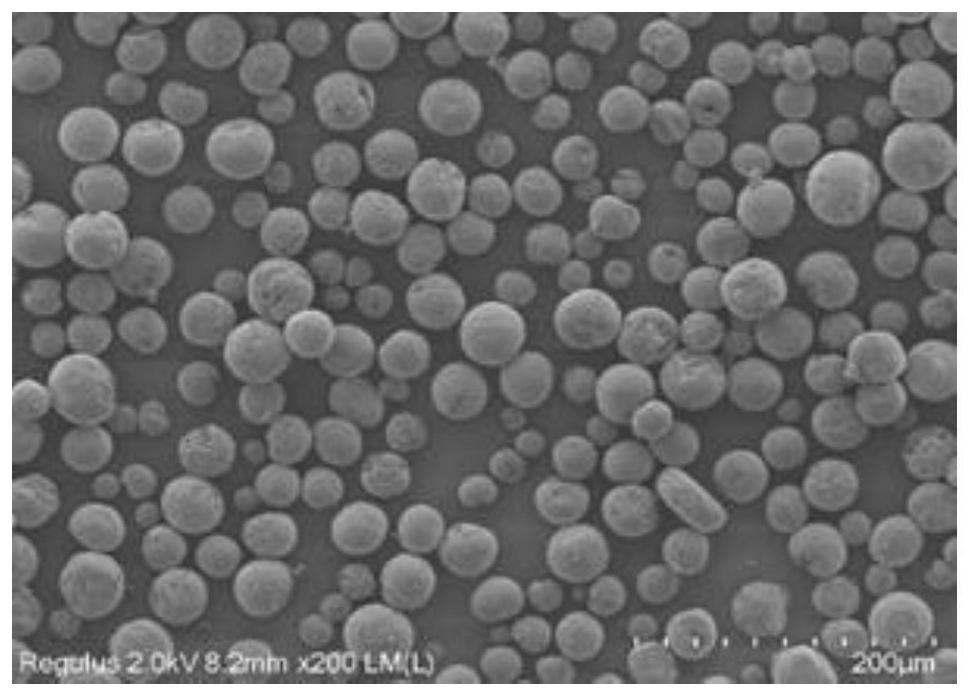

[0038] S2: Take 200g of polyvinyl alcohol (PVA) aqueous solution with a mass concentration of 2% and place it in a 500ml beaker, place it in a 65°C water bath for temperature control; place the PVA aqueous solution at 65°C under a homogenizer, and cut Slowly add 2g of polycaprolactone particles at 8000rpm, the time is controlled within 40s, and the shearing time is 10min; the obtained solution is transferred to a magnetic stirrer, and magnetically stirred at 300rpm for 2h; wet ball sieve, 300 mesh sieve On the upper side, the 800-mesh sieve is on the lower side to obtain wet balls; after sieving, wash with water and centrifuge; dry in an oven at 40°C; sieve through 300-mesh dry bal...

Embodiment 2

[0041] S1: After feeding liquid nitrogen into the liquid nitrogen pulverizer, add polycaprolactone into the liquid nitrogen pulverizer for pulverization while freezing to obtain polycaprolactone particles, the particle size of which is about 75 μm; Weigh 2g polycaprolactone granules and set aside;

[0042] S2: Take 200g of polyvinyl alcohol (PVA) aqueous solution with a mass concentration of 2% and place it in a 500ml beaker, place it in a 65°C water bath for temperature control; place the PVA aqueous solution at 65°C under a homogenizer, and cut Slowly add 2g polycaprolactone particles at 13000rpm, the time is controlled within 40s, and the shearing time is 10min; the obtained solution is transferred to a magnetic stirrer, and magnetically stirred at 300rpm for 2h; wet ball sieve, 300 mesh screen On the upper side, the 800-mesh sieve is on the lower side to obtain wet balls; after sieving, wash with water and centrifuge; dry in an oven at 40°C; sieve through 300-mesh dry ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com