Culture method of artificial high-quality pit mud for pottery-melt type white spirit

A cultivation method, pottery-melting technology, applied in the field of brewing technology, can solve the problems of long cycle, slow influence on wine quality, unsatisfactory, etc., and achieve the effect of strong strain, strong reproductive and metabolic ability, and low deformity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

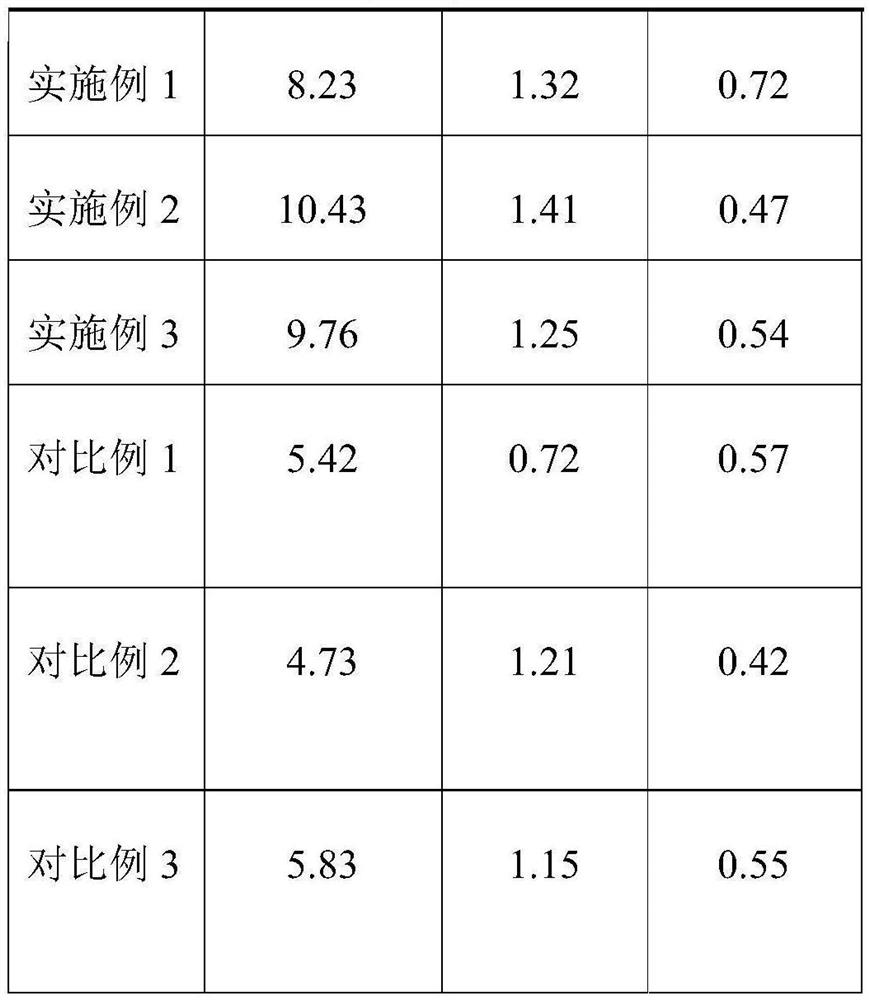

Embodiment 1

[0042] The present embodiment provides a method for cultivating pottery-type liquor artificial high-quality pit mud, comprising the following steps:

[0043] 1) Soil selection: choose red soil with a cation exchange capacity of 6 cmol / kg as the basic pit mud;

[0044] 2) Soil drying: drying the selected red soil for 6 days at a sunshine temperature of 30°C;

[0045] 3) Grinding soil: Grinding the red clay after sterilization, so that the ground red clay can pass through a 150-mesh sieve;

[0046] 4) Mixing: Add the bacillus liquid mixed with Bacillus licheniformis, Bacillus subtilis and Bacillus amyloliquefaciens to the ground red soil and 40 parts of yellow clay, 35 parts of organic-rich mud, and 8 parts of medium-temperature koji powder 6 parts, 6 parts of double-wheel bottom wine fermented grains, 12 parts of ammoniacal nitrogen substances, 4 parts of dipotassium hydrogen phosphate, 5 parts of pit mud, 6 parts of caproic acid bacteria liquid, 2 parts of alcohol, 1 part of ...

Embodiment 2

[0052] The present embodiment provides a method for cultivating pottery-type liquor artificial high-quality pit mud, comprising the following steps:

[0053] 1) Soil selection: choose red soil with a cation exchange capacity of 8cmol / kg as the basic pit mud;

[0054] 2) Soil drying: drying the selected red soil for 8 days at a sunshine temperature of 32°C;

[0055] 3) Grinding soil: Grinding the red clay after sterilization, so that the ground red clay can pass through a 150-mesh sieve;

[0056] 4) Mixing: Add the Bacillus bacteria liquid mixed with Bacillus licheniformis, Bacillus subtilis and Bacillus amyloliquefaciens to the ground red soil and 43 parts of yellow clay, 37 parts of organic-rich mud, and 9 parts of medium-temperature koji powder. 7 parts of double-wheel bottom wine grains, 13 parts of ammoniacal nitrogen substances, 6 parts of dipotassium hydrogen phosphate, 8 parts of pit mud, 7 parts of caproic acid bacteria liquid, 3 parts of alcohol, 2 parts of wine tail...

Embodiment 3

[0062] The present embodiment provides a method for cultivating pottery-type liquor artificial high-quality pit mud, comprising the following steps:

[0063] 1) Soil selection: choose red soil with a cation exchange capacity of 10cmol / kg as the basic pit mud;

[0064] 2) Soil drying: drying the selected red soil for 10 days at a sunshine temperature of 35°C;

[0065] 3) Grinding soil: Grinding the red clay after sterilization, so that the ground red clay can pass through a 150-mesh sieve;

[0066] 4) Mixing: Add the bacillus liquid mixed with Bacillus licheniformis, Bacillus subtilis and Bacillus amyloliquefaciens and 45 parts of yellow clay, 38 parts of organic-rich mud, and 10 parts of medium-temperature koji powder into the ground red soil. 8 parts of double-wheel bottom wine fermented grains, 15 parts of ammonia nitrogen substance, 8 parts of dipotassium hydrogen phosphate, 10 parts of pit mud, 9 parts of caproic acid bacteria liquid, 5 parts of alcohol, 3 parts of wine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com