Method for improving Baijiu quality by carbon-based solid acid

A carbon-based solid acid and liquor technology, applied in the field of liquor processing, can solve the problems of irreplaceability, difficult food industry, low density of effective acid centers, etc., to improve quality, reduce storage sites and equipment, and have strong acid catalysis and adsorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

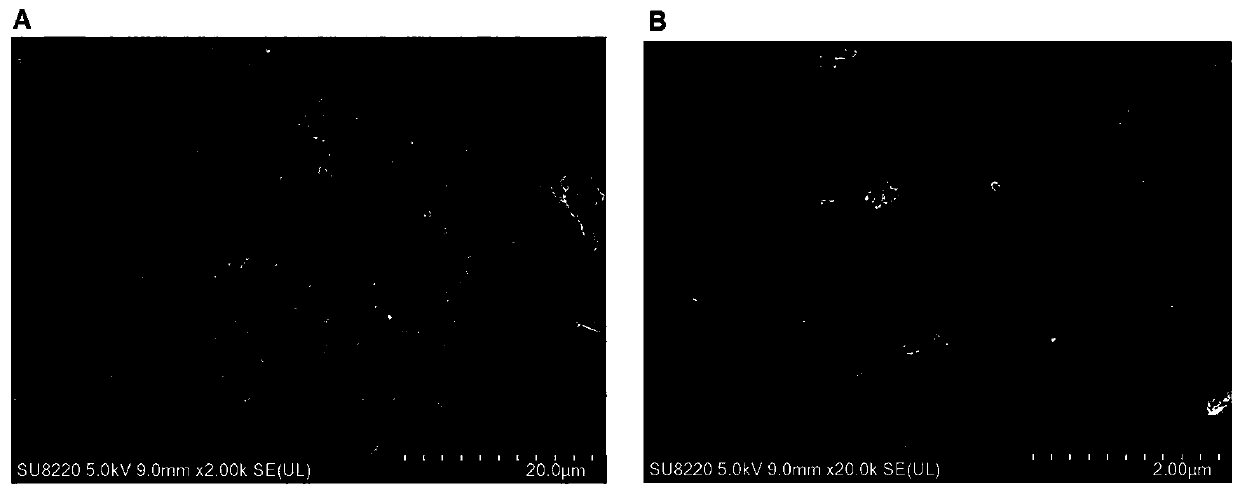

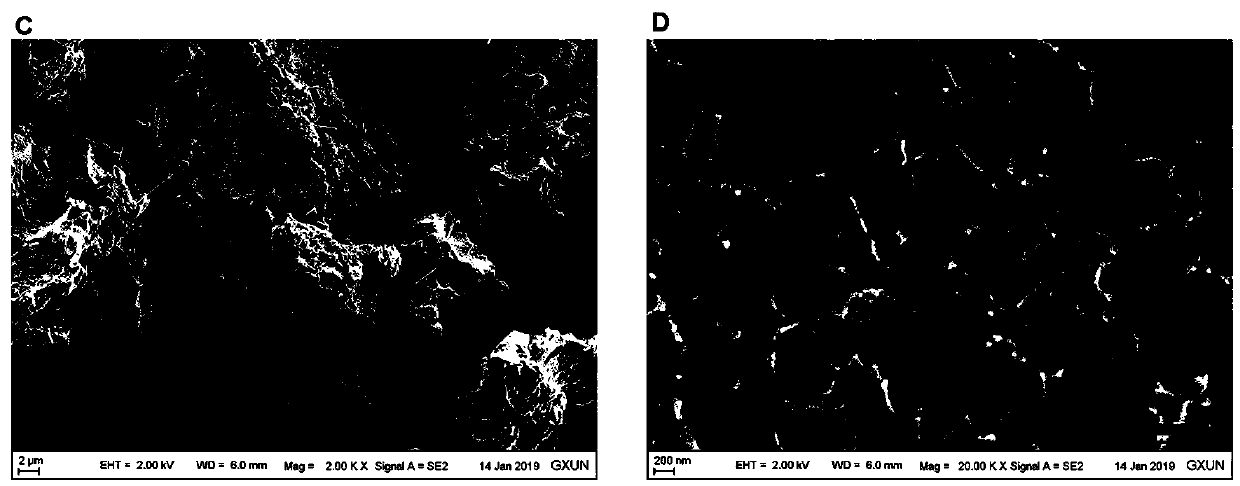

Image

Examples

Embodiment 1

[0023] Using wood powder processed from tree branches or wood processing waste as raw material, dissolve 50g of phosphoric acid in 100mL of water according to the mass ratio phosphoric acid:wood powder ratio of 1:1, add 50g of wood powder, stir and soak for 4h, at 110℃ Then heat carbonization / activation at 350°C for 3h, cool to room temperature, soak in water overnight, wash with suction, dry the obtained carbon material at 110°C, and then use 300mL of concentrated sulfuric acid with a mass fraction of 98% at 170 After sulfonation at ℃ for 8 hours, fully washed with water and dried to obtain a carbon-based solid acid with a specific surface area of 890 m2 / g. The carbon-based solid acid accounting for 0.05% by mass of liquor is put into liquor, sealed, stored at room temperature for more than 2 months, and filtered to obtain a 22.5% increase in total ester content, significantly reduced irritation and acrid feeling, and improved taste. The liquor with improved aroma and signi...

Embodiment 2

[0025] Using alkali lignin as raw material, according to the mass ratio potassium hydroxide: alkali lignin ratio of 2:1, dissolve 100g of potassium hydroxide in 80mL of water, add 50g of lignin, stir and soak for 5h, the amount of water added is based on the amount of It is advisable to dry a small amount of solution at 110°C, then heat carbonization / activation at 400°C for 3 hours, cool to room temperature, soak in dilute hydrochloric acid overnight, filter and wash with water, dry the obtained carbon material at 110°C, and then use 300mL98% After concentrated sulfuric acid was sulfonated at 180°C for 8 hours, it was fully washed with water and dried to obtain a carbon-based solid acid with a specific surface area of 400.6 m2 / g. The carbon-based solid acid accounting for 0.1% of the mass percentage of the liquor is dropped into the liquor, sealed, stored at room temperature for more than 2 months, filtered, and the total ester content of the obtained liquor is increased by 2...

Embodiment 3

[0027]Using eucalyptus wood powder as raw material, dissolve 150g of phosphoric acid in 100mL of water according to the ratio of phosphoric acid:wood powder by mass ratio of 3:1, add 50g of eucalyptus wood powder, stir and soak for 4h, dry at 110°C, and then heat and carbonize at 350°C / Activated for 3 hours, cooled to room temperature, soaked in water overnight, washed by suction filtration, dried the obtained carbon material at 110°C, and then sulfonated with 250mL oleum at 140°C for 4h, then fully washed with water and dried to obtain the ratio Carbon-based solid acid with a surface area of more than 1200 m2 / g. The carbon-based solid acid that accounts for 0.25% of the mass percentage of the liquor is dropped into the liquor, sealed, stored at room temperature for 1 month, filtered, and the total ester content of the liquor obtained is increased by 18.7%, and the irritation and pungency are obviously alleviated. The taste and aroma are improved, and the quality is signif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com