Confined range type pyrite cinder/iron oxychloride composite light-Fenton catalyst as well as preparation method and application of limited range type pyrite cinder/iron oxychloride composite light-Fenton catalyst

A technology of pyrite slag and composite light, which is applied in the field of photo-Fenton catalyst, can solve the problems of difficult control of structure and morphology, low catalytic degradation activity of organic pollutants, etc., and achieves good recycling performance and good separation and recovery performance. , the effect of improving the catalytic degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

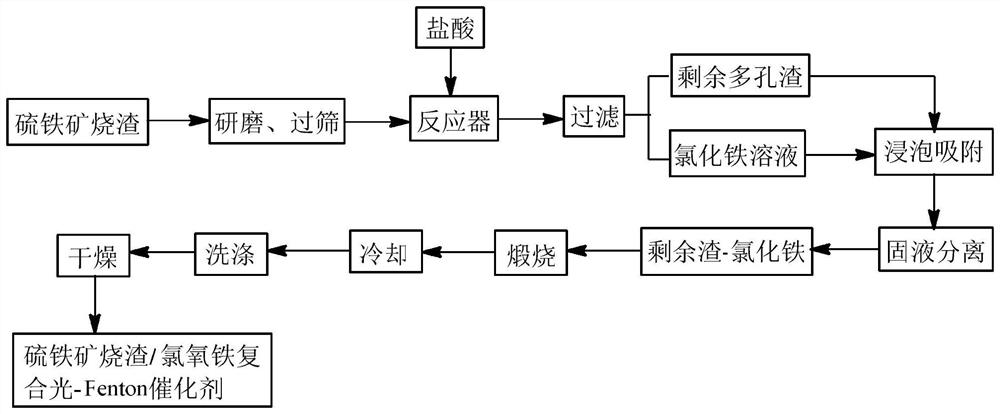

[0036] (1) Get 20g of the pyrite slag that has been ground to 80 mesh sieves and add it to a 250mL three-necked bottle with mechanical stirring, dripping device and reflux condenser, and then press the hydrochloric acid volume to the pyrite slag mass ratio to be 1.49 mL: 1g, add 29.8mL of hydrochloric acid solution with a mass percentage concentration of 20.02% dropwise into the reactor, start the stirrer at the same time, and reflux at a stirring speed of 250r / min and 85°C for 1.5h;

[0037] (2) The reaction mixture of step (1) is filtered, and the filtrate is collected for use, i.e. ferric chloride solution; the filter residue is washed with distilled water until the washing water reaches near neutrality; the washing water is collected for the next round of hydrochloric acid solution preparation, and the filter residue is washed Place in a blast drying oven at 105°C and dry to constant weight to obtain 12.94 g of remaining porous slag;

[0038] (3) Add the remaining porous s...

Embodiment 2

[0040] (1) Get 20g of pyrite slag that has been ground to 80 mesh sieves and add it to a 250mL three-necked bottle with mechanical stirring, dripping device and reflux condenser, and then press the hydrochloric acid volume to pyrite slag mass ratio to be 1.74 mL: 1g, 34.8mL mass percent concentration is 22.61% hydrochloric acid solution (preparation with the washing water that embodiment 1 step (2) collects) is added dropwise in the reactor, starts agitator simultaneously, at 220r / min stirring speed and Reflux reaction at 80°C for 2h;

[0041] (2) The reaction mixture of step (1) is filtered, and the filtrate is collected for use, i.e. ferric chloride solution; the filter residue is washed with distilled water until the washing water reaches near neutrality; the washing water is collected for the next round of hydrochloric acid solution preparation, and the filter residue is washed Place in a blast drying oven at 105°C and dry to constant weight to obtain 11.80 g of residual r...

Embodiment 3

[0044] (1) Get 20g of pyrite slag that has been ground to 80 mesh sieves and add it to a 250mL three-necked bottle with mechanical stirring, dripping device and reflux condenser, and then press the hydrochloric acid volume to pyrite slag mass ratio to be 1.99 mL: 1g, 39.8mL mass percent concentration is 24.55% hydrochloric acid solution (prepared with the washing water that embodiment 2 step (2) collects) dropwise in the reactor, start stirrer simultaneously, at 200r / min stirring speed and Reflux reaction at 75°C for 2h;

[0045] (2) The reaction mixture of step (1) is filtered, and the filtrate is collected for use, i.e. ferric chloride solution; the filter residue is washed with distilled water until the washing water reaches near neutrality; the washing water is collected for the next round of hydrochloric acid solution preparation, and the filter residue is washed Place in a blast drying oven at 105°C and dry to constant weight to obtain 9.79 g of residue;

[0046] (3) Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com