Visible-light-responsive zinc stannate/bismuth oxyiodide composite photocatalytic material and preparation method thereof

A technology of composite photocatalysis and composite materials, which is applied in the field of zinc stannate/bismuth oxyiodide composite photocatalytic materials and its preparation, can solve the problem of unsatisfactory photocatalytic performance, narrow spectral response range, and photogenerated electron-hole recombination. High efficiency and other problems, to achieve excellent photocatalytic properties, high application value, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

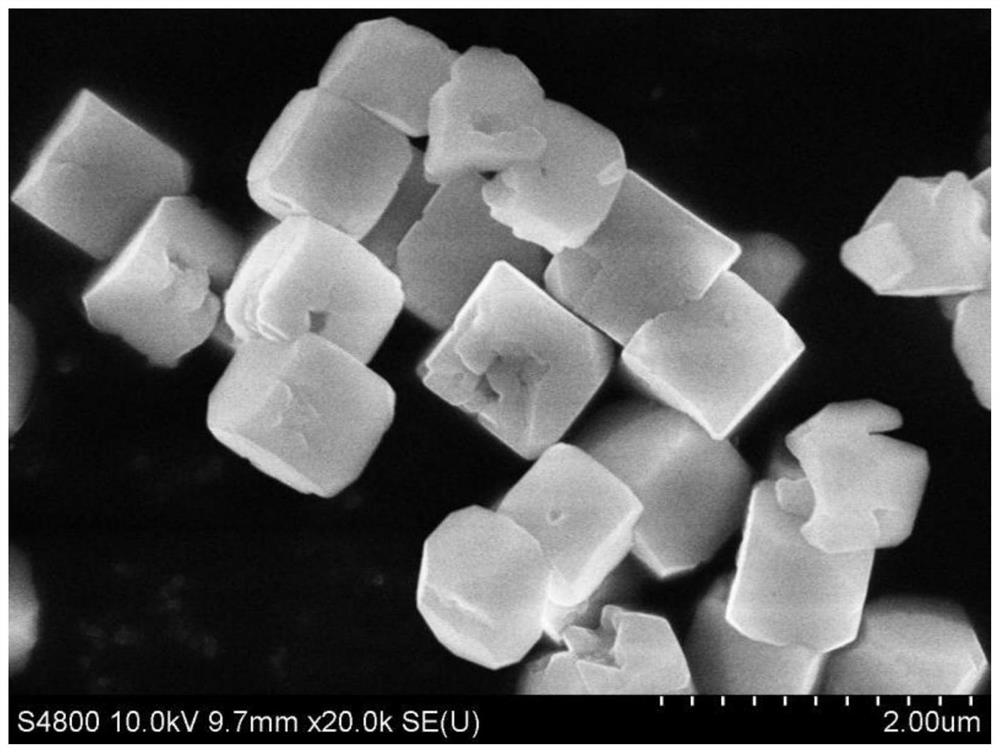

[0036] Weigh respectively tin tetrachloride pentahydrate and zinc acetate dihydrate in equimolar amounts and dissolve them in a certain volume of ethylene glycol, marked as A, wherein the molar concentration of tin tetrachloride pentahydrate is 0.05 M; then hydrogen Potassium oxide is dissolved in a certain volume of deionized water, marked as B, the concentration of solution B is 0.5 M, and the volume ratio of solution B to solution A is 0.6; under magnetic stirring, slowly add solution B to solution A , continue to stir for 30 minutes to obtain zinc stannate precursor solution; transfer the mixed solution after uniform stirring to a stainless steel reaction kettle with polytetrafluoroethylene lining, and heat it in a solvent at 120 ° C for 20 hours; At room temperature, centrifuge to separate the precipitate, wash the obtained sample several times with deionized water and absolute ethanol, and dry at 80°C to obtain a pure zinc stannate sample with a hollow cubic structure. Th...

Embodiment 2

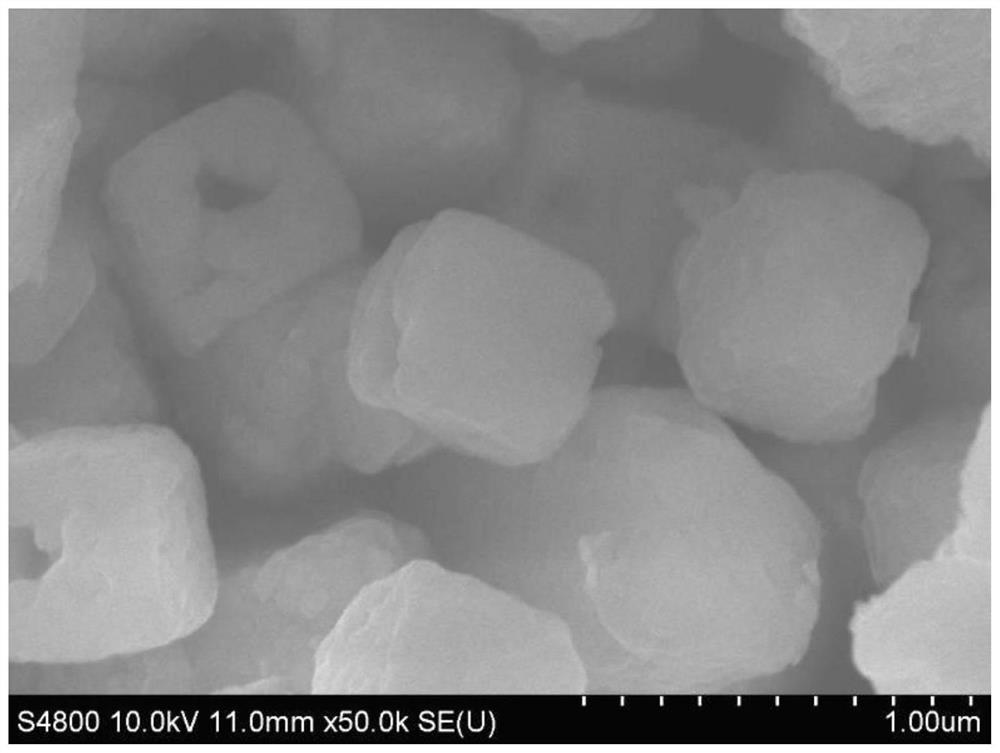

[0039] Weigh respectively tin tetrachloride pentahydrate and zinc acetate dihydrate in equimolar amounts and dissolve them in a certain volume of ethanol, marked as A; wherein, the molar concentration of tin tetrachloride pentahydrate is 0.08 M; then potassium hydroxide Dissolve in a certain volume of deionized water, marked as B, the concentration of solution B is 0.6 M, and the volume ratio of solution B to solution A is 0.1; under magnetic stirring, slowly add solution B to solution A, continue Stir for 30 minutes to obtain the zinc stannate precursor solution; transfer the mixed solution after uniform stirring to a stainless steel reaction kettle lined with polytetrafluoroethylene, and heat it in a solvent at 140 ° C for 16 hours; after the reaction is completed, cool to room temperature naturally, The precipitate was separated by centrifugation, and the obtained sample was washed several times with deionized water and absolute ethanol, and dried at 80°C to obtain a pure zi...

Embodiment 3

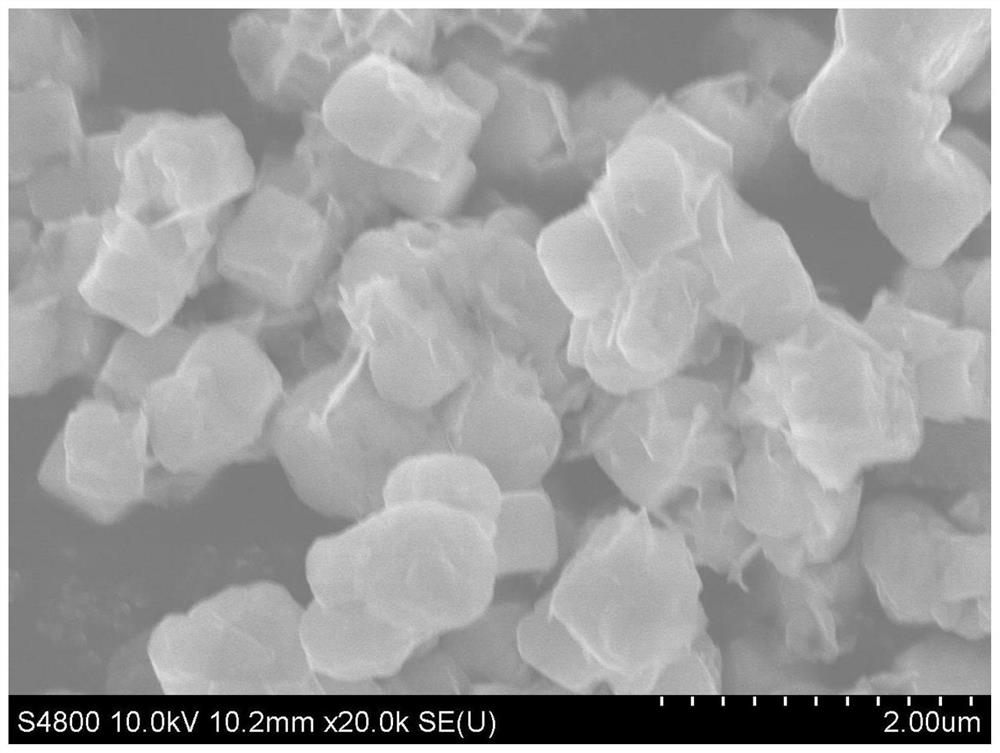

[0042] Weigh equimolar amounts of tin tetrachloride pentahydrate and zinc acetate dihydrate and dissolve them in a certain volume of deionized water, marked as A; wherein, the molar concentration of tin tetrachloride pentahydrate is 0.1 M; Potassium is dissolved in a certain volume of deionized water, marked as B, the concentration of solution B is 0.8M, and the volume ratio of solution B to solution A is 0.75; under magnetic stirring, slowly add solution B to solution A, Stirring was continued for 30 minutes to obtain zinc stannate precursor solution; the mixed solution after stirring was transferred to a stainless steel reaction kettle with polytetrafluoroethylene lining, and the hydrothermal method was carried out at 140 ° C for 12 hours; after the reaction was completed, it was naturally cooled to At room temperature, the precipitate was separated by centrifugation, and the obtained sample was washed several times with deionized water and absolute ethanol, and dried at 80°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com