Glass powder suitable for crystalline silicon p + layer contact and used for thick film silver paste and preparation method of glass powder

A glass powder and crystalline silicon technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of high glass softening temperature, inability to meet high square resistance, low square resistance, etc., to optimize contact performance, reduce contact resistance and Metal-induced recombination rate, the effect of promoting rapid formation

Pending Publication Date: 2022-04-22

GUANGDONG NANHAI ETETB TECH CO LTD +1

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

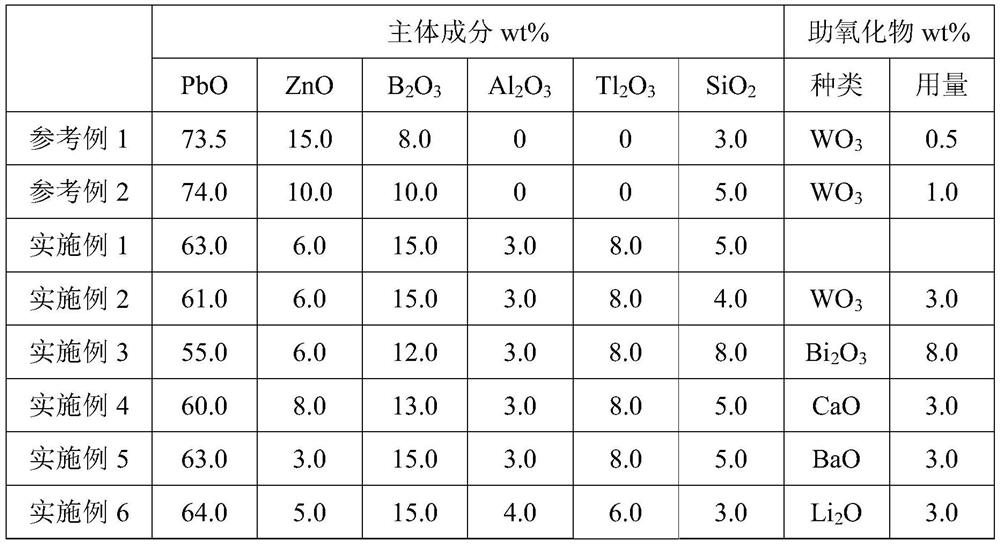

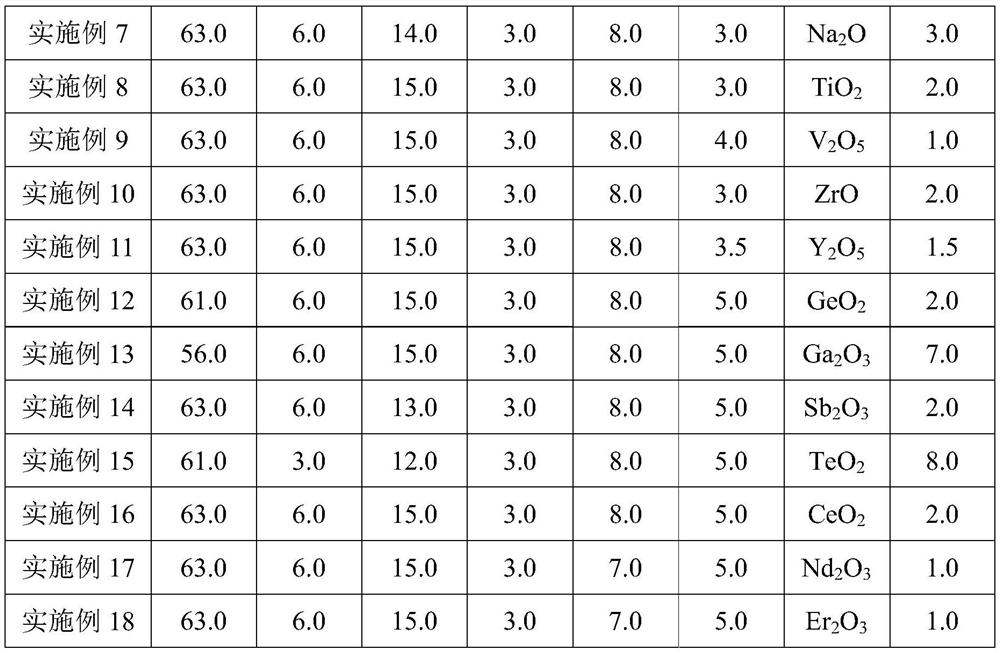

[0028] Reference example 1-2 and embodiment 1-18 provide a kind of glass powder, the preparation raw material of described glass powder is by weight percentage, as shown in table 1:

[0029] Table 1

[0030]

[0031]

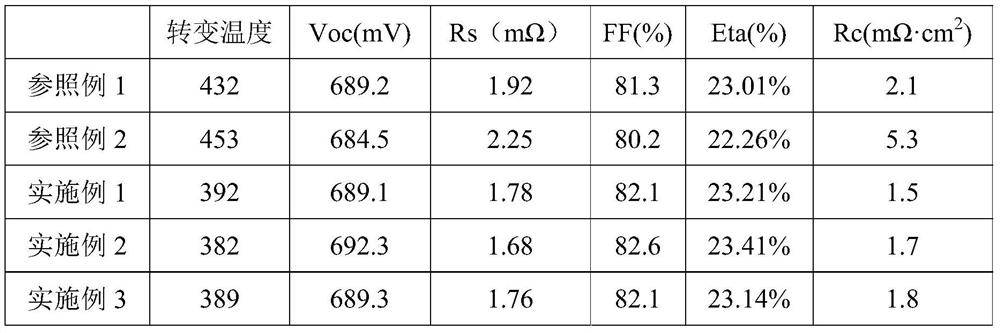

[0032] performance evaluation

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to C03C, in particular to glass powder suitable for crystalline silicon p + layer contact and used for thick film silver paste and a preparation method of the glass powder. The preparation raw materials of the glass powder comprise a metal oxide and a non-metal oxide. According to the glass powder for the thick film silver paste suitable for crystalline silicon p + layer contact, the glass powder is introduced into the thick film silver paste, so that the metal-semiconductor contact resistance and the metal induced recombination speed can be reduced. By controlling the particle size and the use amount of the glass powder, rapid formation of silver microcrystals in silver paste sintering can be promoted, corrosion to a doping layer and formation of aluminum pinning are reduced, and the open-circuit voltage and the filling factor of the cell are improved. The glass powder provided by the invention can be used in TOPCon cell silver-aluminum paste, optimizes the metal-semiconductor contact performance of the silver-aluminum paste and a p + layer of a crystalline silicon solar cell, reduces metal induced recombination, improves the open-circuit voltage of the solar cell, and improves the photoelectric conversion efficiency of an N-type or P-type TOPCon crystalline silicon solar cell.

Description

technical field [0001] The present invention relates to C03C, and more specifically, the present invention relates to the field of functional glass frit materials, which can be used as raw materials for preparing thick-film silver pastes, and related thick-film silver pastes can be applied to the p+ layer surface of N-type crystalline silicon solar cells to realize electrode and Ohmic contact of the p+ layer. Background technique [0002] Solar cell power generation technology, as a new power generation technology that is clean, environmentally friendly, safe and reliable, rich in resources, and wide in application fields, is one of the most promising energy utilization technologies in the future world. At present, the mainstream photovoltaic technology is mainly P-type rear passivated local contact cell (PERC cell), the industrialization efficiency is 22.5-23.3%, but limited by the industrialization of PERC cell technology, the highest conversion efficiency is about 24.5%. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03C12/00C03C8/24H01L31/0224

CPCC03C12/00C03C8/24H01L31/022425

Inventor 刘家敬李宇杨至灏黄良辉

Owner GUANGDONG NANHAI ETETB TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com