Method for combined co-mining of deep coal bed gas and coal by using multi-mode microwave radiation

A technology of microwave radiation and coalbed methane, applied in the direction of mining fluid, electrical components, earthwork drilling and mining, etc., can solve the problems of inability to effectively reduce formation pressure, difficult decompression and desorption of coalbed methane, and lower mining efficiency, so as to ensure effective mining, Wide heating range and the effect of improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

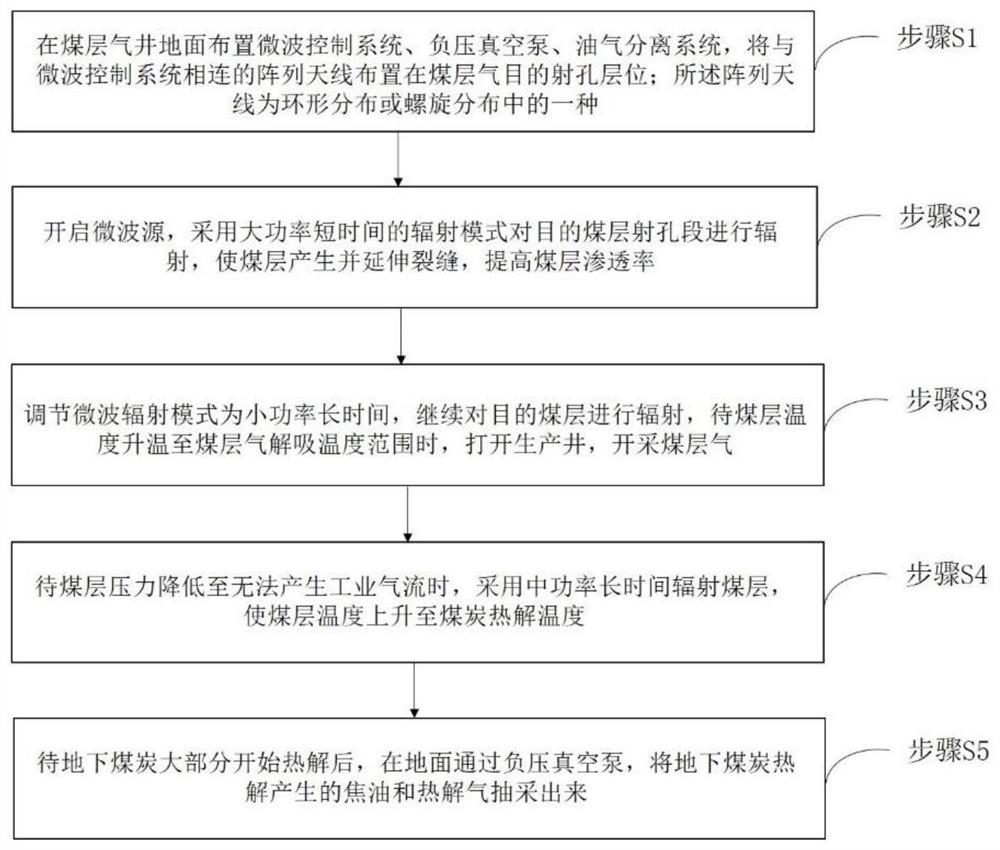

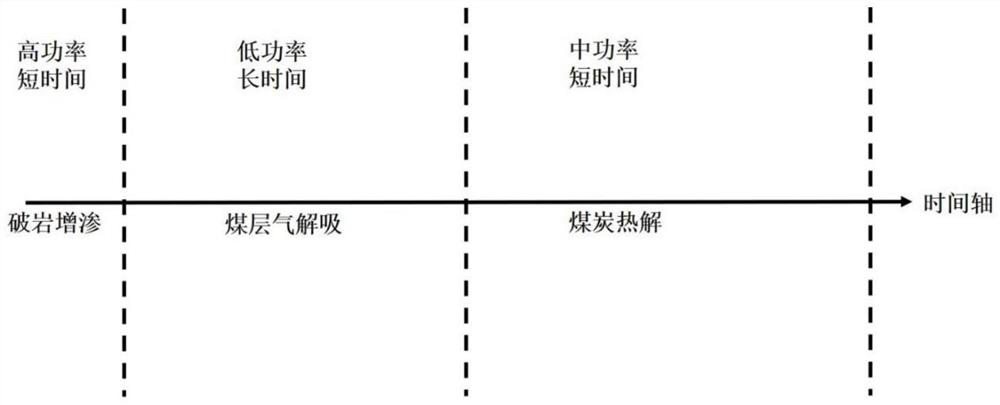

[0032] A method for combined mining of deep coalbed methane and coal by using multi-mode microwave radiation, comprising the following steps:

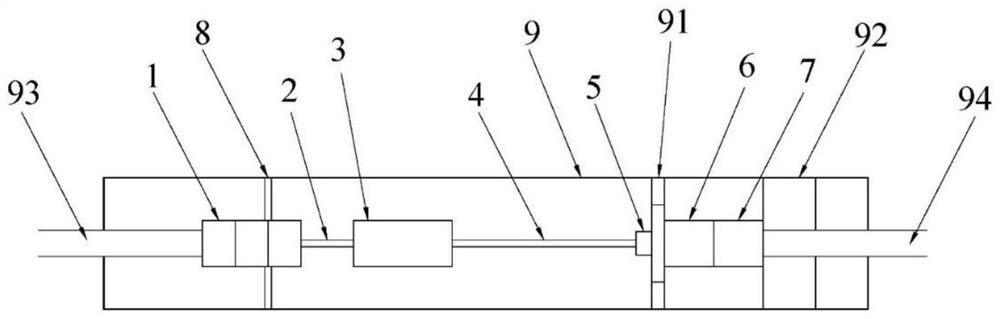

[0033] S1: Arrange a microwave control system, a negative pressure vacuum pump, and an oil-gas separation system on the ground of the coalbed methane well, and arrange the array antenna connected to the microwave control system at the target perforation layer of the coalbed methane; the array antenna is distributed in a ring;

[0034] S2: Turn on the microwave source, and use 4000W microwave radiation power to irradiate the coal seam for 10 minutes, so as to generate and extend cracks in the coal seam and increase the permeability of the coal seam;

[0035] S3: Adjust the microwave radiation power to 400W, and continue to radiate the target coal seam. When the temperature of the coal seam rises to 200°C, open the production well and exploit coalbed methane; continue to radiate the target coal seam with a power of 200W, and the radiation...

Embodiment 2

[0040] A method for combined mining of deep coalbed methane and coal by using multi-mode microwave radiation, comprising the following steps:

[0041] S1: Arrange a microwave control system, a negative pressure vacuum pump, and an oil-gas separation system on the ground of the coalbed methane well, and arrange the array antenna connected to the microwave control system at the target perforation layer of the coalbed methane; the array antenna is helically distributed;

[0042] S2: Turn on the microwave source and irradiate the coal seam with 8000W microwave radiation power for 2 minutes to generate and extend cracks in the coal seam and increase the permeability of the coal seam;

[0043] S3: Adjust the microwave radiation power to 400W, and continue to radiate the target coal seam. When the temperature of the coal seam rises to 200°C, open the production well and exploit coalbed methane; continue to radiate the target coal seam with a power of 200W, and the radiation time is 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com