Reverse conduction semiconductor device and method for manufacturing reverse conduction semiconductor device

A technology of reverse conduction and semiconductor, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of increased manufacturing cost, concentration difference, and complicated impurity addition process, and achieve high latch-up tolerance, Avoid manufacturing costs, avoid greatly increased effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

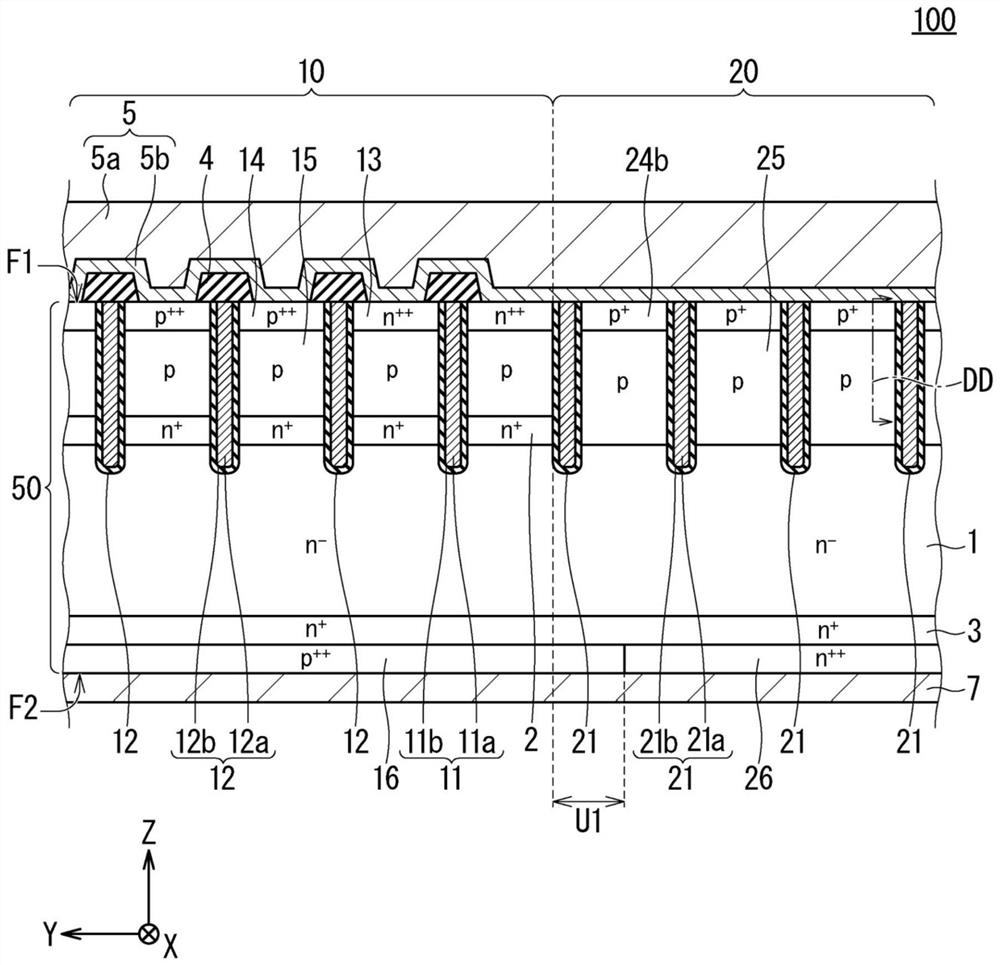

[0126] Figure 17 so with figure 2 The same field of view schematically shows a partial plan view of the structure of the RC-IGBT 102 (reverse conduction type semiconductor device) viewed along the upper surface (first main surface) of the semiconductor substrate 50 according to the second embodiment. In Embodiment 2, the same as Embodiment 1 ( figure 2 ) different, p + The anode contact layer 24b is p ++ The anode contact layer 24a surrounds the configuration at p ++ The inner side of the anode contact layer 24a. In addition, since the configuration other than that is substantially the same as that of the above-mentioned first embodiment, the same or corresponding elements are given the same reference numerals, and the description thereof will not be repeated.

[0127] In common with Embodiments 1 and 2, in p + The anode contact layer 24b is provided with a p-type by further counter-doping an acceptor to a region where a donor is added. Therefore, at the upper surfac...

Embodiment approach 5

[0136] Figure 20 so with Figure 17 The same field of view schematically shows a partial plan view of the structure of the RC-IGBT 105 (reverse conduction type semiconductor device) viewed along the upper surface (first main surface) of the semiconductor substrate 50 according to the fifth embodiment. In Embodiment 5, the same as Embodiment 2 ( Figure 17 ) different, p ++ Anode contact layer 24a is p + The anode contact layer 24b surrounds the configuration at p + The inner side of the anode contact layer 24b. In other words, transposing p ++ Anode contact layer 24a and p + Configuration of the anode contact layer 24b. In addition, since the configuration other than that is substantially the same as that of the above-mentioned second embodiment, the same or corresponding elements are given the same reference numerals, and the description thereof will not be repeated.

[0137] According to the present embodiment, the density of holes injected into the p-type anode lay...

Embodiment approach 6

[0139] Figure 21 so with figure 2 The same field of view schematically shows a partial plan view of the structure of the RC-IGBT 106 (reverse conduction type semiconductor device) viewed along the upper surface (first main surface) of the semiconductor substrate 50 according to the sixth embodiment. In this embodiment, with Embodiment 5 ( Figure 20 ) is different from p + Anode contact layer 24b surrounded by p ++ The anode contact layer 24a is scattered and arranged in a zigzag shape. In addition, since the configuration other than that is substantially the same as that of the above-mentioned fifth embodiment, the same reference numerals are attached to the same or corresponding elements, and the description thereof will not be repeated.

[0140] According to this embodiment 6 ( Figure 21 ), and Embodiment 5 ( Figure 20 ), the hole current density at the diode region 20 becomes more equal. Thereby, the heat dissipation of the diode region 20 can be improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com