High-concentration organic waste gas treatment and recycling system

A technology of organic waste gas and high concentration, which is applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high-concentration waste gas treatment difficulty, etc., to improve the efficiency of waste liquid treatment, avoid excessive discharge, and improve removal rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

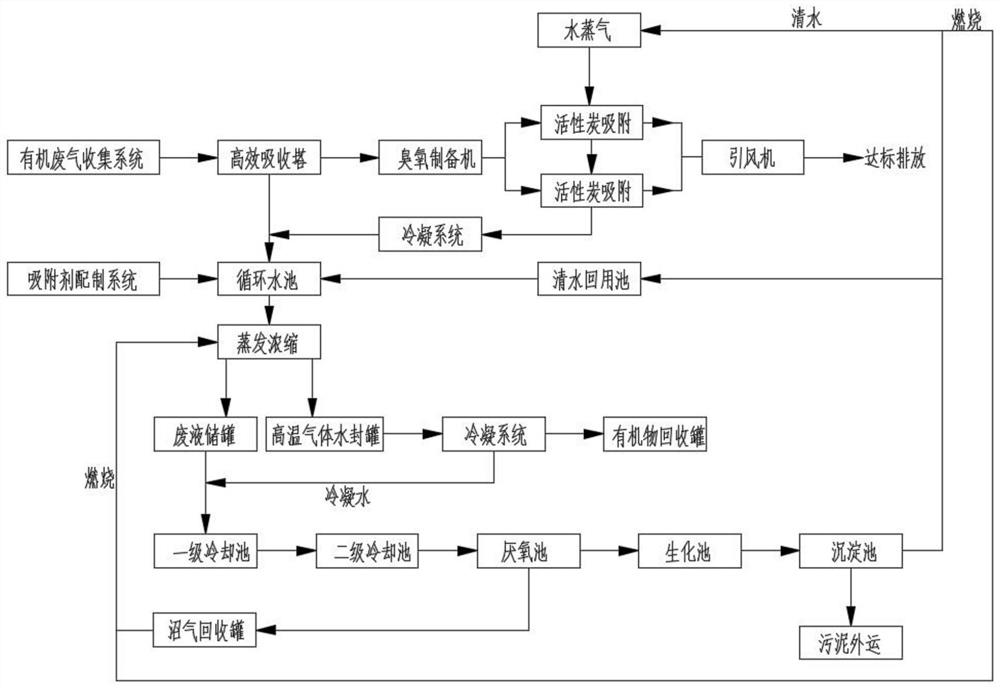

[0030] like figure 2As shown, the main technological process for the recovery of high-concentration organic waste gas in this embodiment includes: the high-concentration organic waste gas collected by the gas collecting hood of the production workshop and the reactor pipeline enters the high-efficiency absorption tower, and the structure inside the absorption tower improves the organic waste gas and the recombination. The contact surface area of the adsorbent, the composite adsorbent preparation system automatically quantitatively prepares the corresponding concentration through the waste gas concentration of the organic waste gas, and uses the principle of similar compatibility to absorb the liquid to dissolve the organic waste gas. It also relies on the microbubbles produced by the adsorbent to increase the absorption contact surface area to enhance the absorption effect of organic waste gas; relying on the porous microgel produced in the absorption process to coat organic...

Embodiment 2

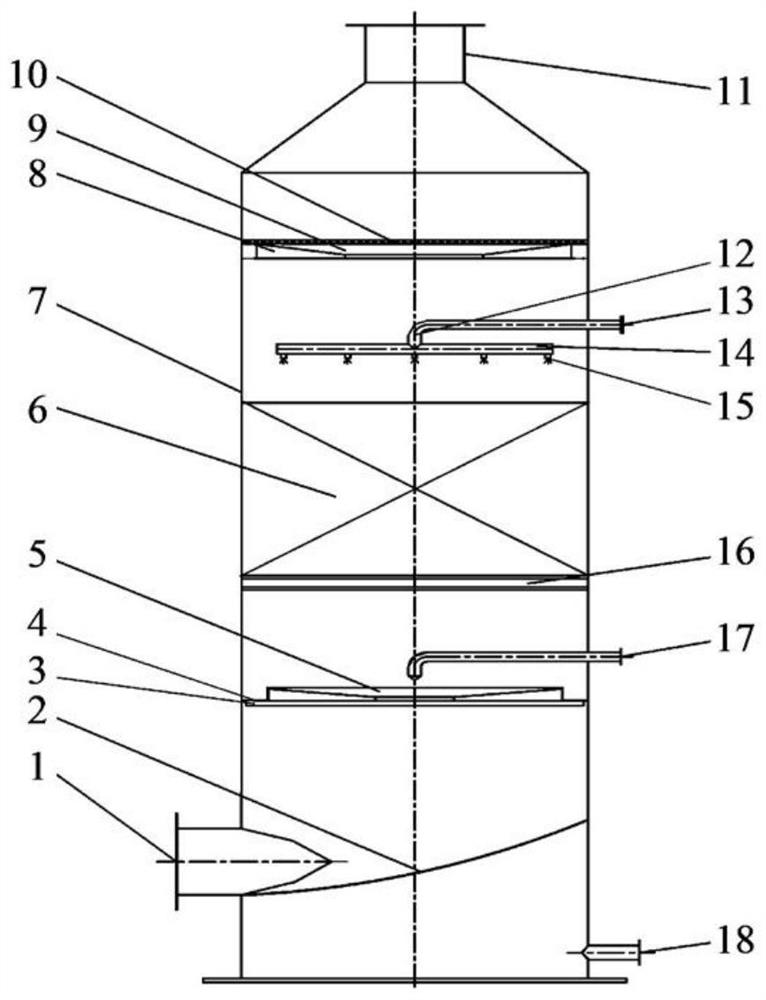

[0033] like figure 1 As shown, this embodiment is used to specifically disclose a high-efficiency absorption tower for high-concentration organic waste gas. The high-efficiency absorption tower includes a tower wall 7. The organic waste gas enters the high-efficiency absorption tower tangentially into the intake pipe 1, and the waste gas moves upwards along the tower wall 7 under the guidance of the deflector 2, and the viscous dust particles in the waste gas are thrown towards the tower wall 7 under the action of the rotating centrifugal force. , the adsorbent flowing down from the liquid collection area of the swirl plate 5 forms a layer of liquid film on the tower wall 7, and the viscous dust particles thrown onto the tower wall 7 are adhered by the liquid film to be purified. The vertical height of the inlet pipe 1 is slightly higher than The vertical height of the discharge pipe 18, a deflector 2 is arranged between the tower walls 7, a liquid film forming baffle 3 is a...

Embodiment 3

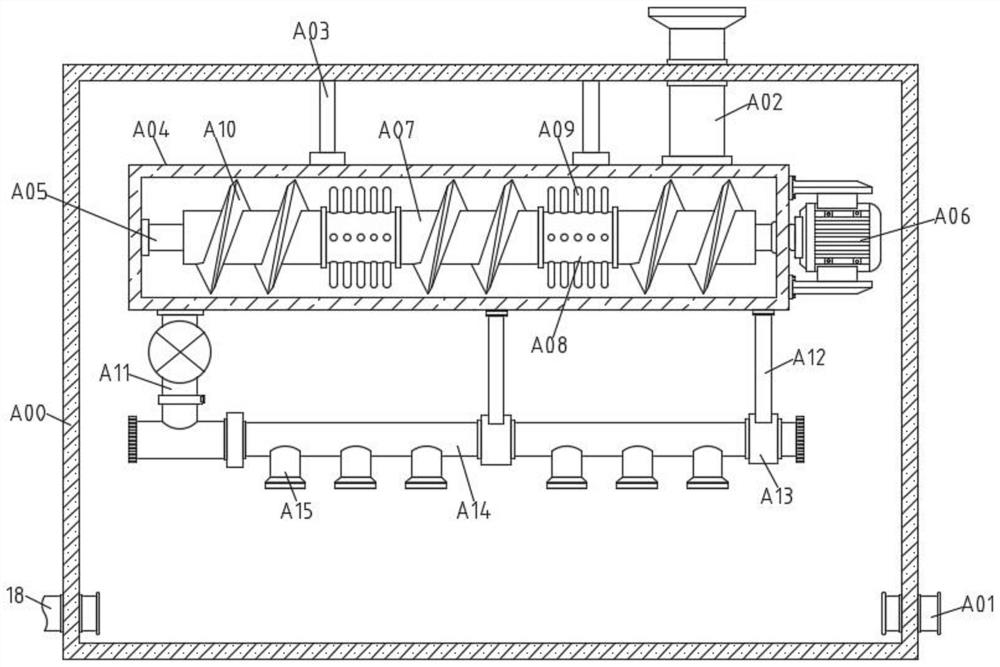

[0035] The difference between this embodiment and Embodiment 2 is that: the end of the drain pipe 18 away from the tower wall 7 is provided with a waste liquid treatment tank A00, and the waste liquid treatment tank A00 can process the waste liquid of the high-efficiency absorption tower in time to prevent the waste liquid from directly The discharge causes environmental pollution, and the waste water is purified by spraying out the treatment liquid. At the same time, the raw materials of the treatment liquid can be directly put into the hopper A02 for mixing. While mixing, the treatment liquid is transported from left to right , so as to improve the efficiency of waste liquid treatment.

[0036] like image 3 As shown, the waste liquid treatment box A00 is connected with the drain pipe 18, the side of the waste liquid treatment box A00 away from the drain pipe 18 is fixedly connected with the liquid outlet pipe A01, and the inner top wall of the waste liquid treatment box A00...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap