Application of monolithic catalyst in catalytic decomposition of ozone

A monolithic catalyst, catalytic decomposition technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, separation methods, etc. Weak, catalyst performance deterioration and other problems, to achieve the effect of high application value and practicability, excellent ozone conversion rate and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides an application of a monolithic catalyst in the catalytic decomposition of ozone, and the specific steps of the application are:

[0039] (1) Weigh 2mmol iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O), 4mmol ammonium fluoride (NH 4 F) Dissolve 5mmol of urea (Urea) in 40mL of deionized water, stir for 20min to mix the solution evenly, add the above solution into a 50mL hydrothermal reaction kettle, and then add a piece of 2×20×30mm nickel foam into the reaction kettle , and then sealed and placed in an oven at 120°C for 6 hours. After the reaction was completed, the hydrothermal kettle was cooled to room temperature, and the obtained monolithic catalyst was washed to neutrality, and dried (60°C, 10h) to obtain a block-shaped monolithic catalyst, which was denoted as : NF-2-4-5-40;

[0040] (2) Cut the block monolithic catalyst into discs with a diameter of 8 mm for later use. A monolithic catalyst with a thickness of 2 mm and a diameter of 8 m...

Embodiment 2

[0042] This embodiment provides an application of a monolithic catalyst in the catalytic decomposition of ozone, and the specific steps of the application are:

[0043] (1) Weigh 2mmol iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O), 4mmol ammonium fluoride (NH 4 F) Dissolve 10mmol of urea (Urea) in 40mL of deionized water, stir for 20min to mix the solution evenly, add the above solution into a 50mL hydrothermal reaction kettle, and then add a piece of 2×20×30mm nickel foam into the reaction kettle , and then sealed and placed in an oven at 120°C for 6 hours. After the reaction was completed, the hydrothermal kettle was cooled to room temperature, and the obtained monolithic catalyst was washed to neutrality, and dried (60°C, 10h) to obtain a block-shaped monolithic catalyst, which was denoted as : NF-2-4-10-40;

[0044] (2) Cut the block monolithic catalyst into discs with a diameter of 8 mm for later use. A monolithic catalyst with a thickness of 2 mm and a diameter of 8...

Embodiment 3

[0046] This embodiment provides an application of a monolithic catalyst in the catalytic decomposition of ozone, and the specific steps of the application are:

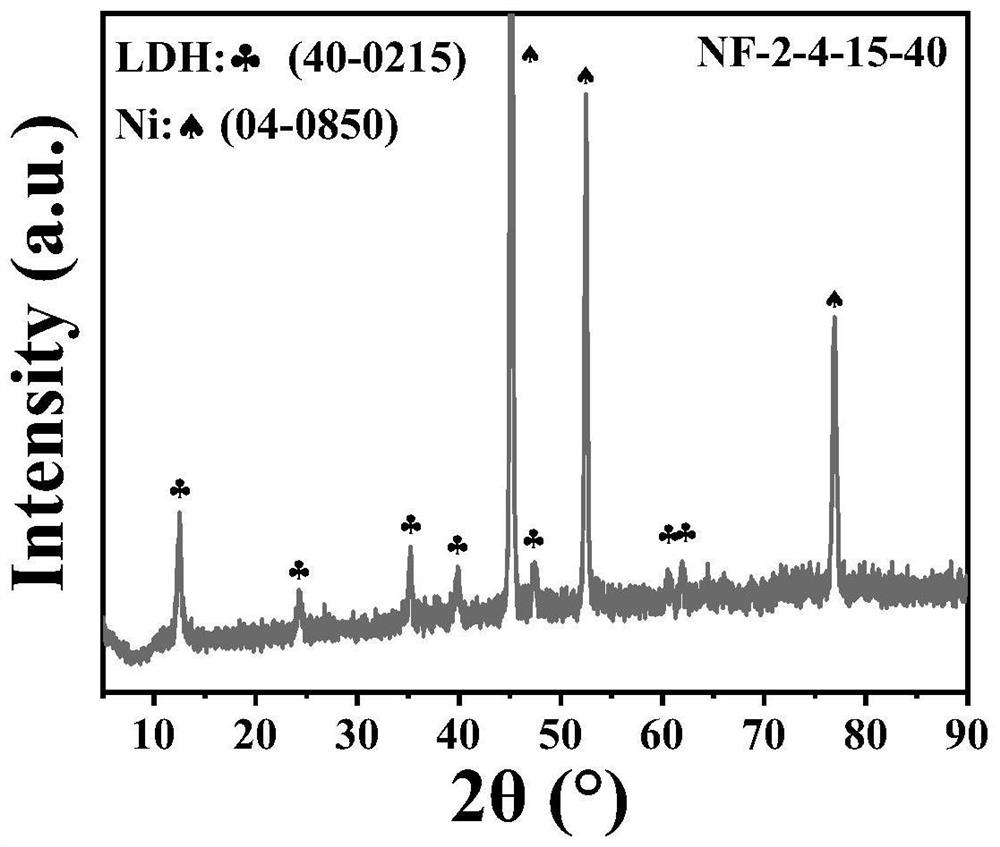

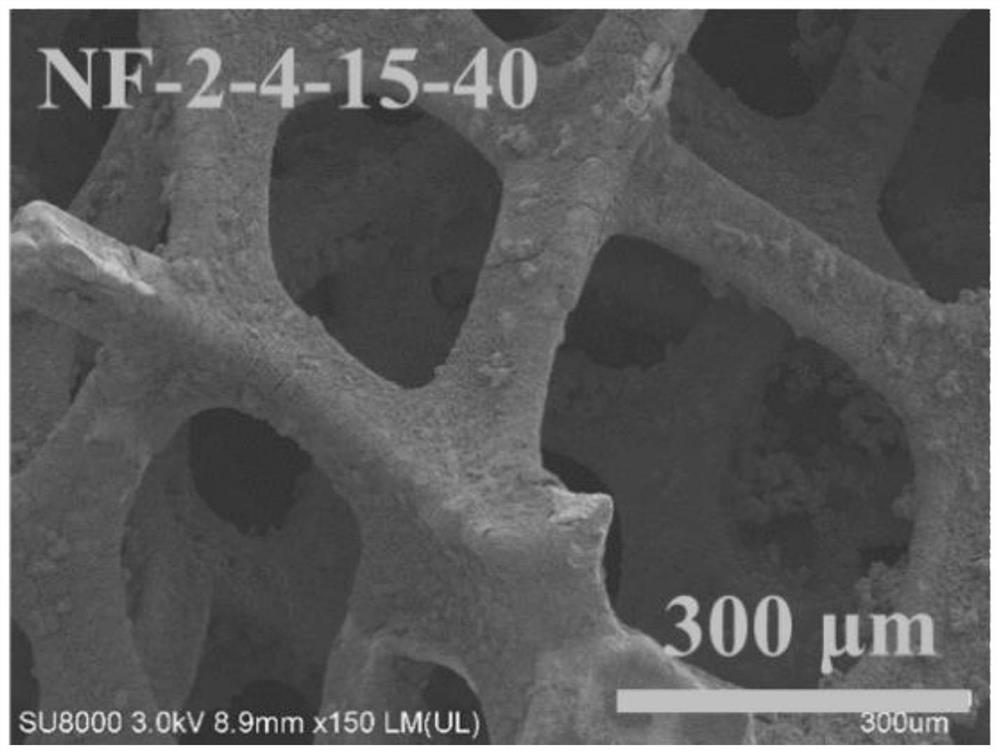

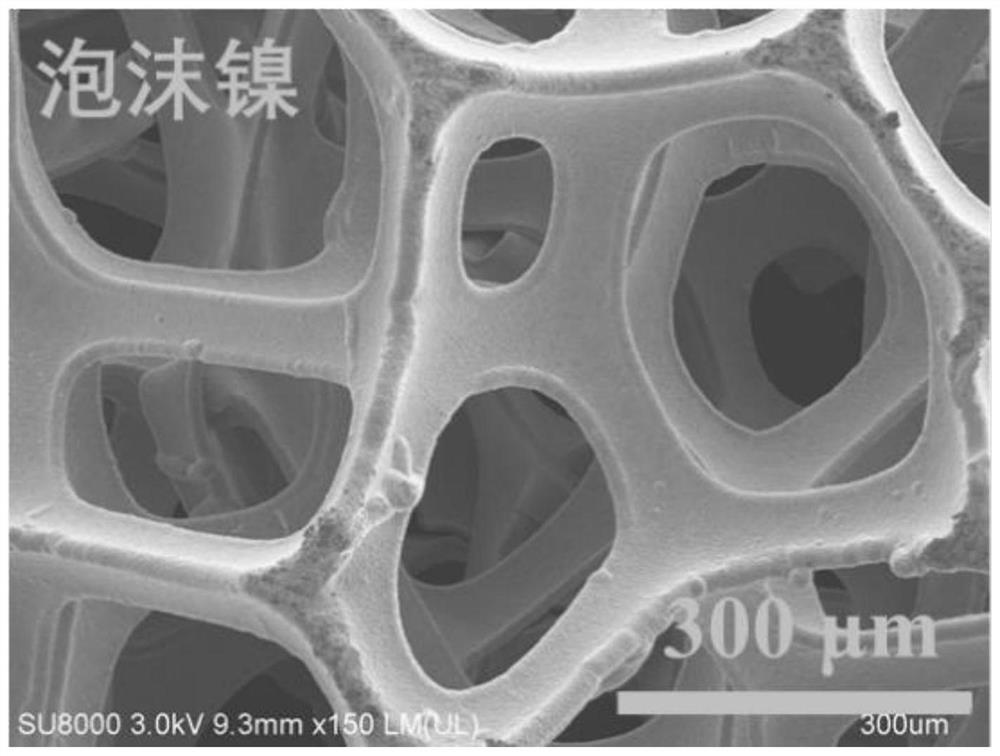

[0047] (1) Weigh 2mmol iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O), 4mmol ammonium fluoride (NH 4 F) Dissolve 15mmol of urea (Urea) in 40mL of deionized water, stir for 20min to mix the solution evenly, add the above solution into a 50mL hydrothermal reaction kettle, and then add a piece of 2×20×30mm nickel foam into the reaction kettle , and then sealed and placed in an oven at 120°C for 6 hours. After the reaction was completed, the hydrothermal kettle was cooled to room temperature, and the obtained monolithic catalyst was washed to neutrality, and dried (60°C, 10h) to obtain a block-shaped monolithic catalyst, which was denoted as : NF-2-4-15-40;

[0048] The XRD figure of described monolithic catalyst is as follows figure 1 As shown, the SEM image of the monolithic catalyst is as follows figure 1 As shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com